Processing technology of web-fed printed wallboard

A processing technology and wallboard technology, used in printing, printing presses, rotary printing machines, etc., can solve the problems of the overall quality of the printing press and the poor interchangeability of wallboards, reducing rework or scrap, and eliminating the need for tool changes. process, the effect of improving perpendicularity and parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

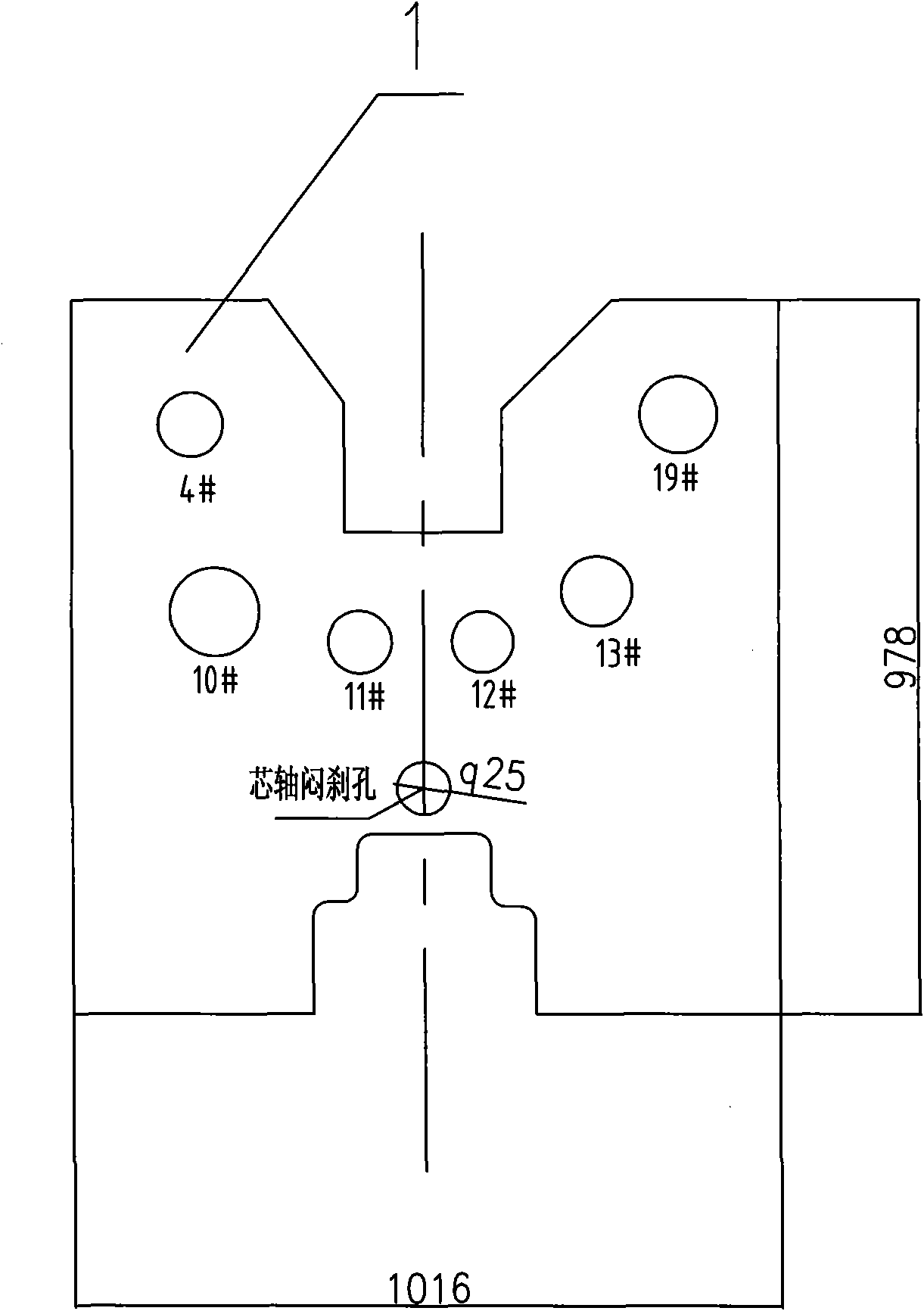

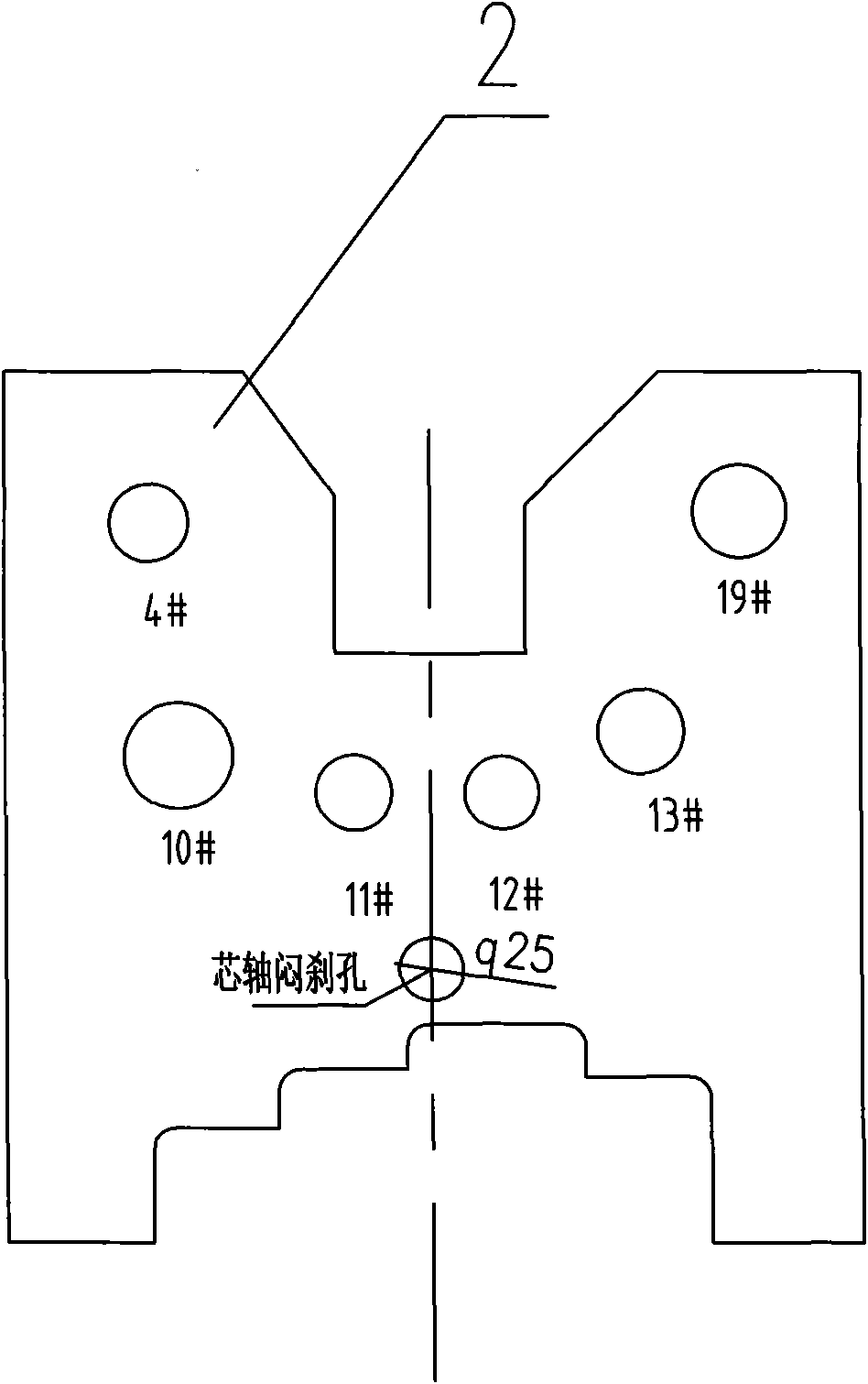

[0072] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the processing technology of the reel printing wallboard, the described reel printing wallboard is composed of two wallboards of high-strength cast iron (HT250) starting surface wallboard 1 and operation surface wallboard 2;

[0073] The process flow is as follows:

[0074] 37. Cross the line

[0075] Taking care of the blank margin and uniform wall thickness, draw two large planes with a size of 305mm for the wall panel on the starting surface;

[0076] 38. Large vertical mill

[0077] Roughly machine the two major planes of the operation surface wallboard 2 by using the rough-fine compound cutter head, leaving 1-2mm allowance on each side;

[0078] 39. Longmen milling

[0079] Roughly process the 1305mm size two planes of the engine surface wallboard 1 single piece and the two planes of the engine surface wallboard and each surface in the box, leaving a margin of 2-3mm on each surface;

[0080] 40. Cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com