Horizontal cooling silo

A cooling warehouse, horizontal technology, applied in the field of cooling storage equipment and cooling storage, can solve the problems of high cost, complex structure, inability to combine storage and cooling, etc., achieve simple structure, improve work efficiency, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

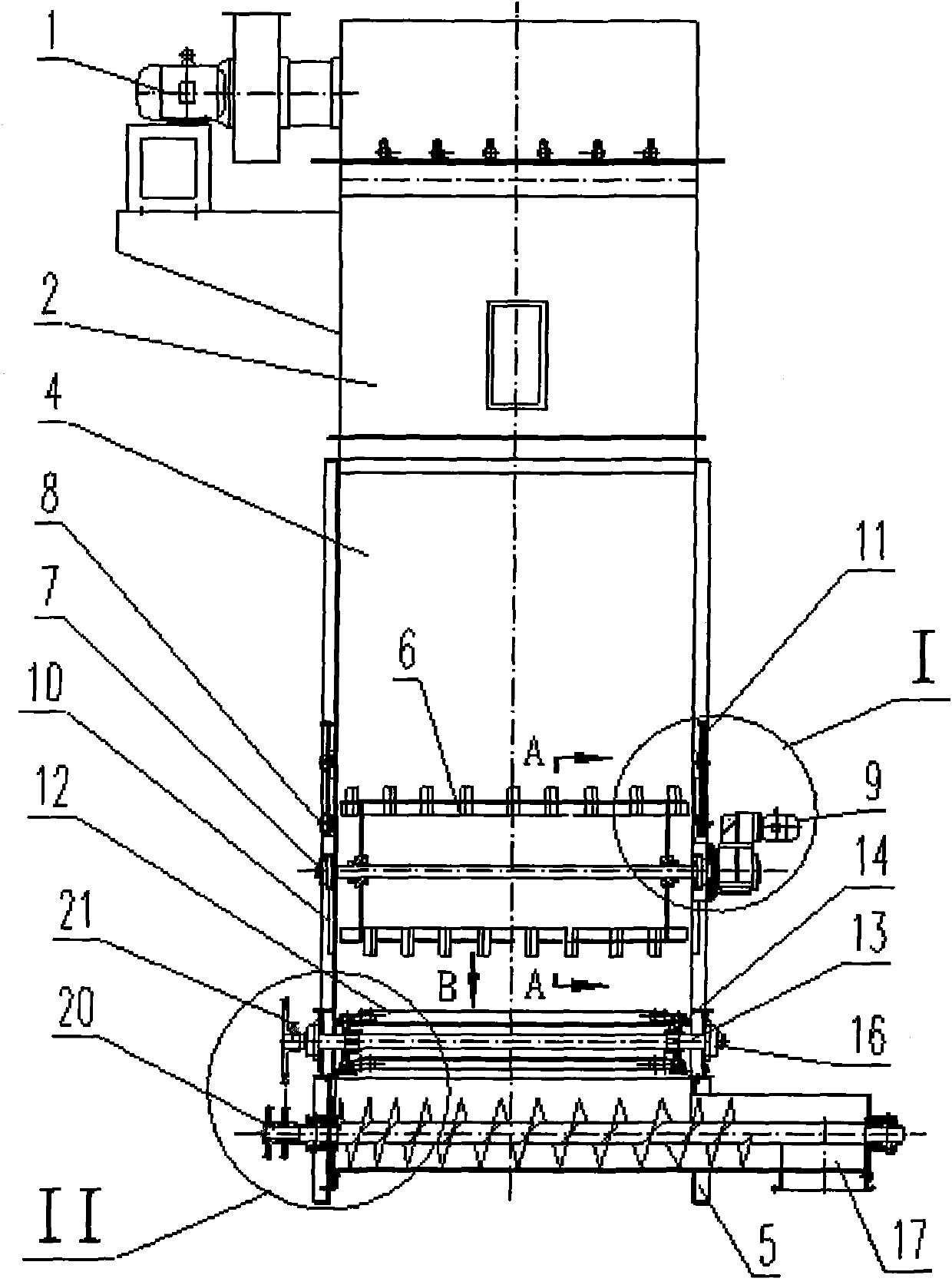

[0022] The present invention will be further described below in conjunction with accompanying drawing:

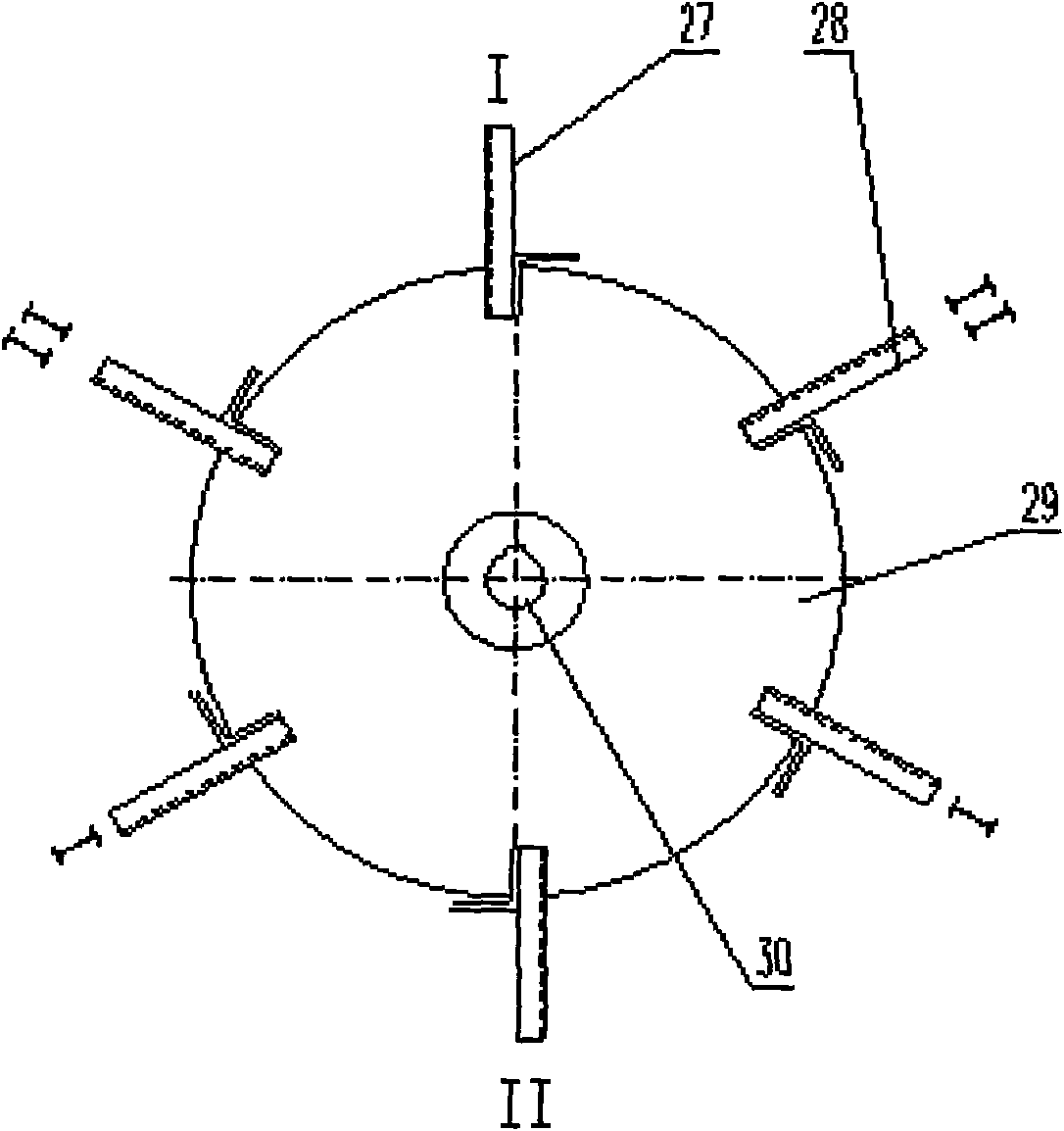

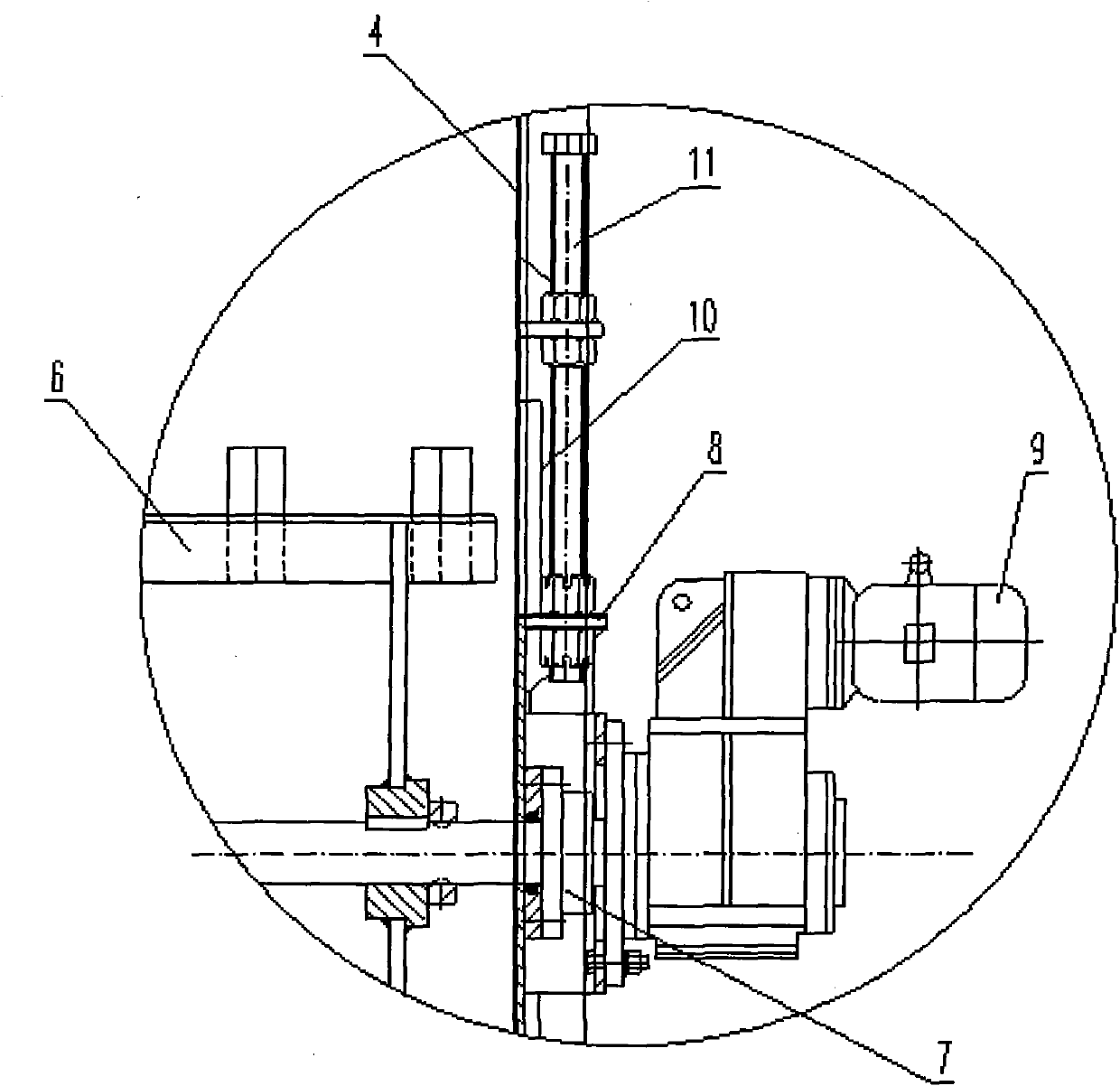

[0023] Such as Figure 1~6 In the shown embodiment, a horizontal cooling bin is specifically composed of a cooling fan 1, a pulse bag filter 2, a silo 4, a conveying material bed 5, a conveying scraper chain assembly 12, and a spreading roller 6. Discharge screw conveyor 17, gear motor, etc. The cooling fan 1 is installed on the air outlet of the pulse bag filter 2, the pulse bag filter 2 is fixed on the top cover of the silo 4, and communicated with each other, and the silo 4 is installed on the conveying material bed 5;

[0024] The conveying scraper chain assembly 12 is driven by the traction sprocket 14 fixed on the transmission main shaft 13, and is supported on the wear-resistant liner 15, which is fixed on the conveying material bed 5, and the transmission main shaft 13 passes through the second The bearing 16 is also fixed on the conveying material bed 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com