Layered-structure anatase titanium-oxide hollow hexagonal nanosheet and preparation method thereof

A layered structure, nanosheet technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high energy consumption, complex reaction, difficult control, etc., and achieve the effect of simple reaction process, easy control and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

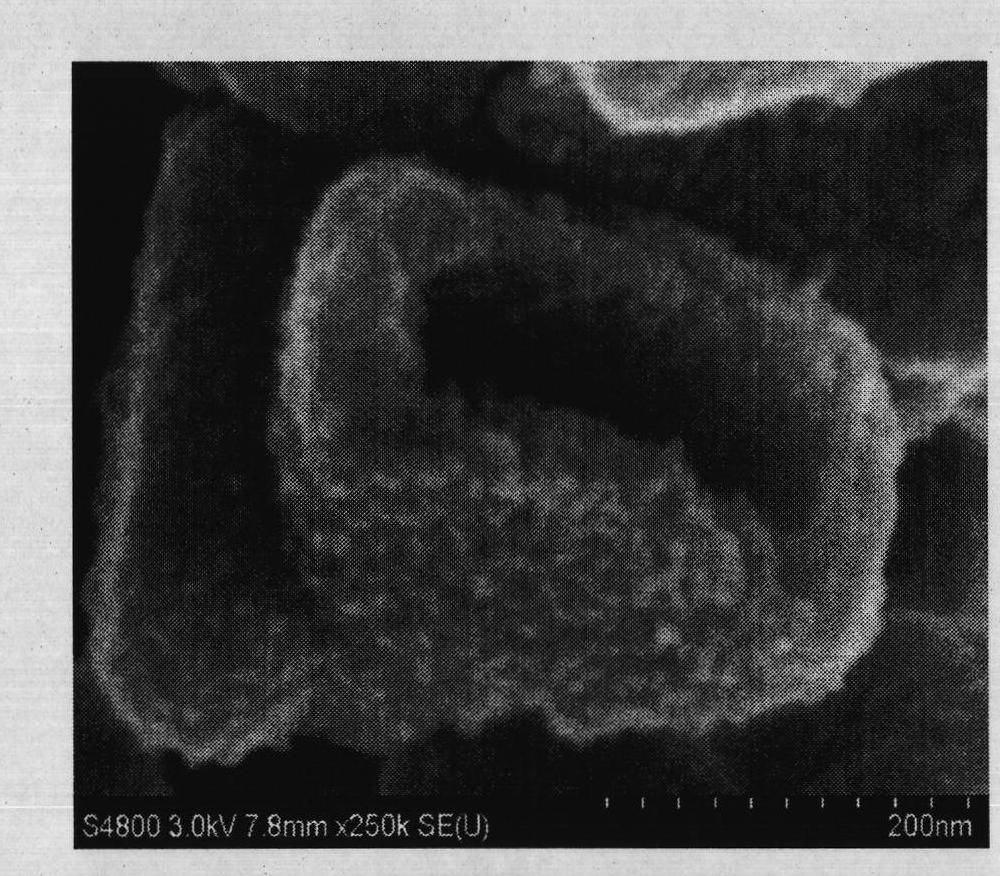

[0016] Example 1 Preparation of hollow hexagonal titanium oxide nanosheets with single-layer structure

[0017] Dissolve 1.48 g of ammonium fluotitanate and 1.24 g of boric acid in 100 ml of deionized water, and magnetically stir until the solution is clear. Disperse 0.23 g of cadmium hydroxide in 10 ml of deionized water, ultrasonically disperse for 10 minutes, add the above-mentioned ammonium fluotitanate / boric acid aqueous solution dropwise to the above-mentioned dispersion solution of cadmium hydroxide nanosheets, and stir magnetically for 120 minutes. The white precipitate was washed with deionized water, dried at 80°C, and sintered at 450°C for 30 minutes to obtain hollow hexagonal titanium oxide nanosheets with a single-layer structure.

Embodiment 2

[0018] Example 2 Preparation of hollow hexagonal titanium oxide nanosheets with single-layer structure

[0019] Other processes are the same as in Example 1. However, the ratio of ammonium fluorotitanate and boric acid was adjusted as follows: 1.48 g of ammonium fluorotitanate and 1.73 g of boric acid were dissolved in 100 ml of deionized water. Hollow hexagonal titanium oxide nanosheets with a single-layer hollow structure were obtained.

Embodiment 3

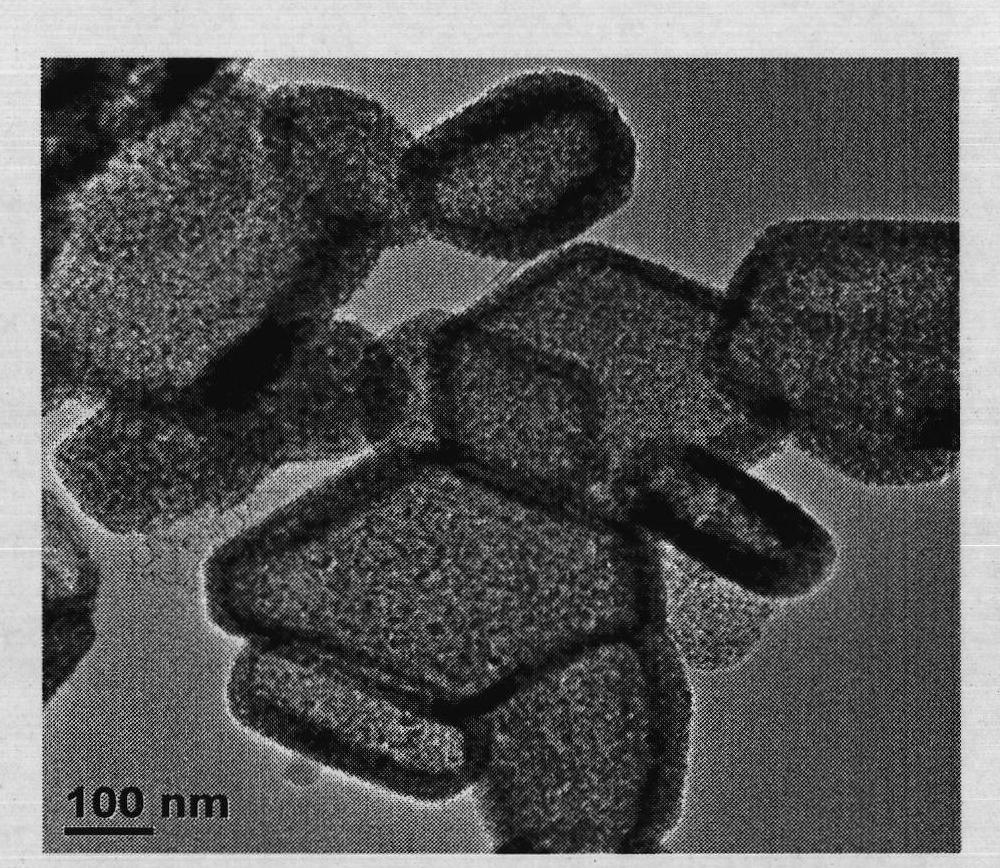

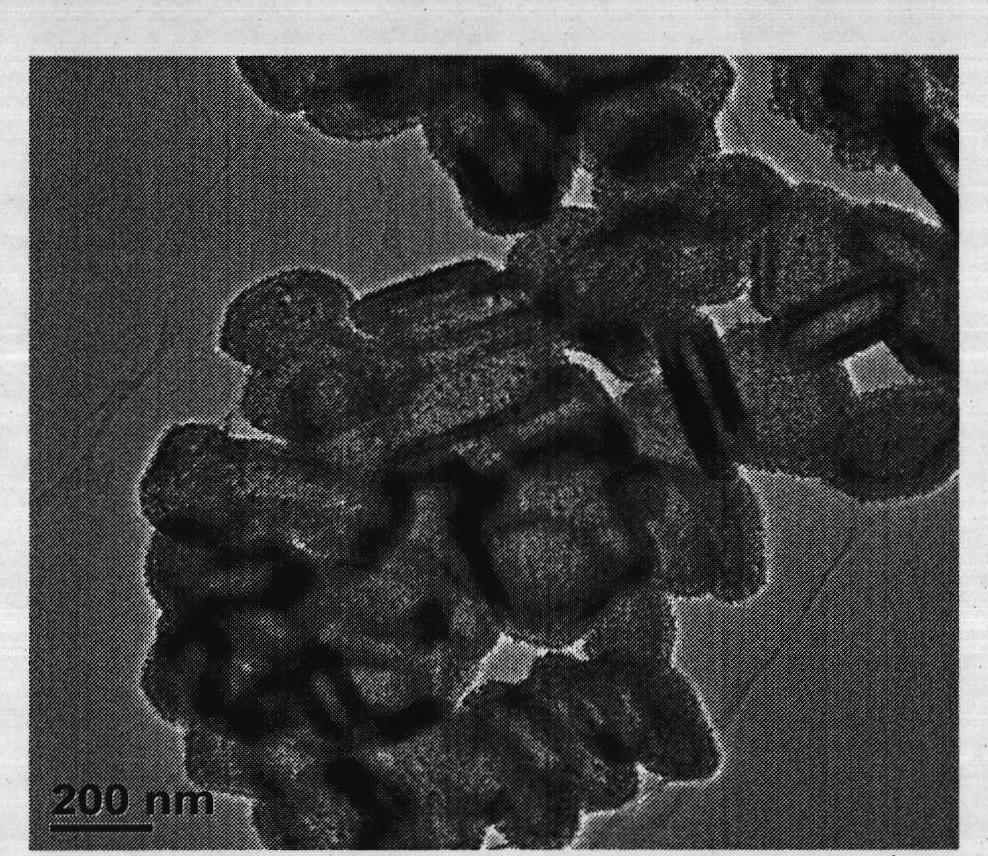

[0020] Example 3 Preparation of hollow hexagonal titanium oxide nanosheets with double-layer structure

[0021] Dissolve 0.98 g of ammonium fluotitanate and 1.22 g of boric acid in 50 ml of deionized water, and magnetically stir until the solution is clear. Disperse 0.11 g of cadmium hydroxide in 5 ml of deionized water and ultrasonically disperse for 10 minutes. Add the above-mentioned ammonium fluorotitanate / boric acid aqueous solution dropwise to the above-mentioned dispersion solution of cadmium hydroxide nanosheets, stir magnetically for 120 minutes, let stand for 12 hours, wash the white precipitate with deionized water, dry it at 80°C, and heat it at 500°C After sintering for 30 minutes, hollow hexagonal titanium oxide nanosheets with double-layer structure were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com