Method for preparing high-purity quartz sand

A high-purity quartz sand and quartz sand technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of large number of enterprises, low variety and small scale, etc., to protect resources and make full use of resources , the effect of wide distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

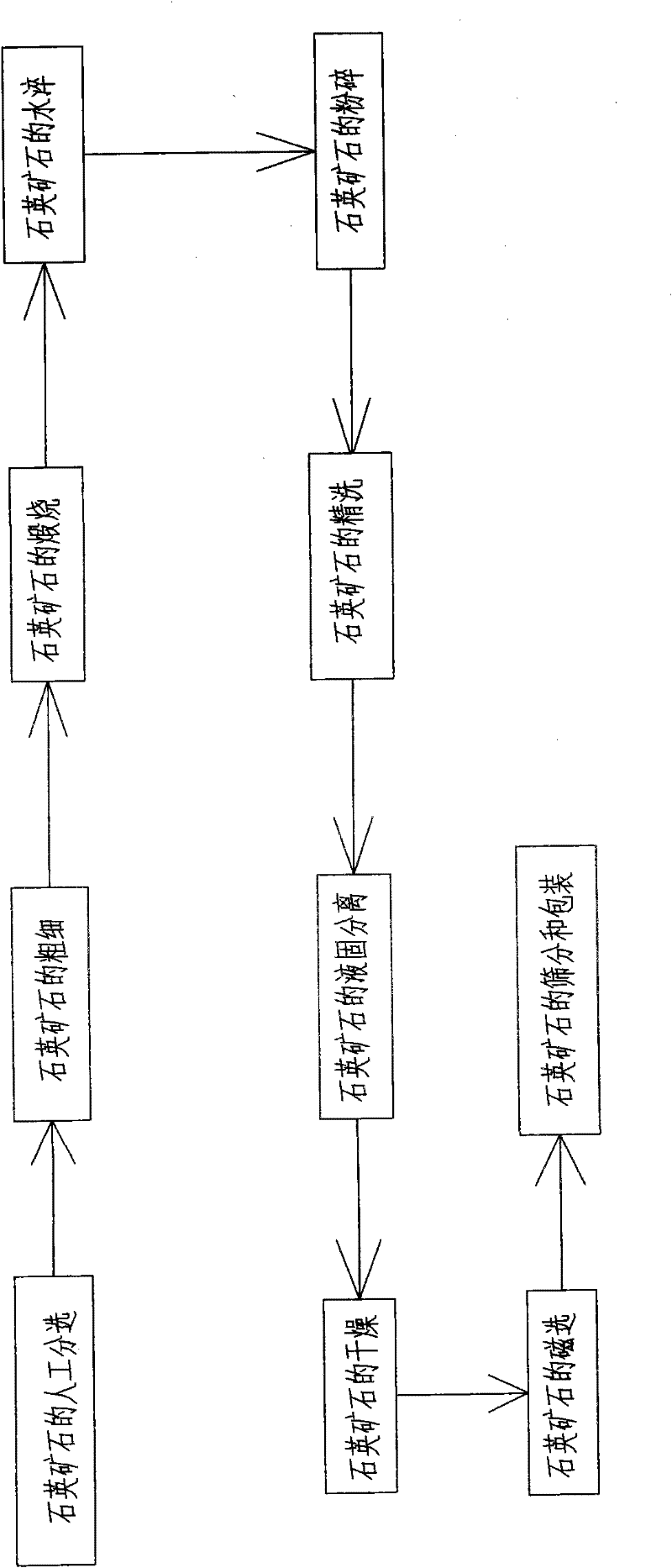

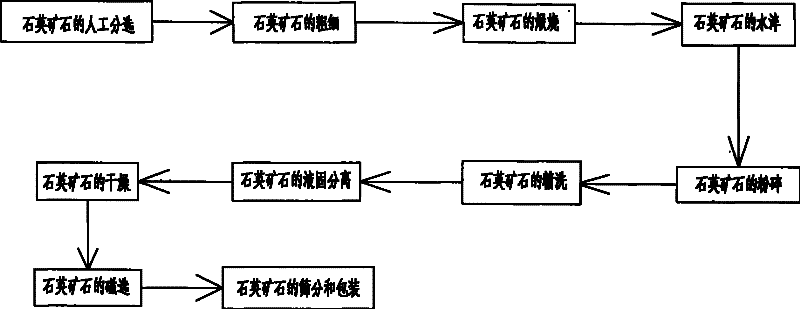

[0037] Accompanying drawing is the program chart of an embodiment of the present invention, in conjunction with accompanying drawing, specifically illustrate this embodiment, in this embodiment, ultrapure water refers to the water that purity level is 14.5-15.5 trillion, and concentrated hydrochloric acid refers to that concentration is 35- 37% hydrochloric acid for laboratory use.

[0038] The steps are:

[0039] 1. Manual sorting of quartz ore

[0040]Manually, the quartz ore is divided into blocks with a size of 30mm×30mm by mechanical means, and the quartz ore is sorted and sorted manually, and the quartz ore blocks with more impurities are selected for use, according to transparency, translucence and white Opaque, followed by first grade, second grade, and third grade, transparent quartz ore blocks are first grade, translucent quartz ore blocks are second grade, white opaque quartz ore blocks are third grade, and are classified and placed in turnover containers.

[0041...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com