Tube-pin bending machine for helical tubes

A screw-type, bending machine technology, applied in glass forming, glass re-forming, glass manufacturing equipment and other directions, can solve the problem that the shape of lamp pins cannot be standardized, the labor intensity of operators is high, and the quality of products is affected. and other problems, to achieve the effects of good product quality, long service life and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

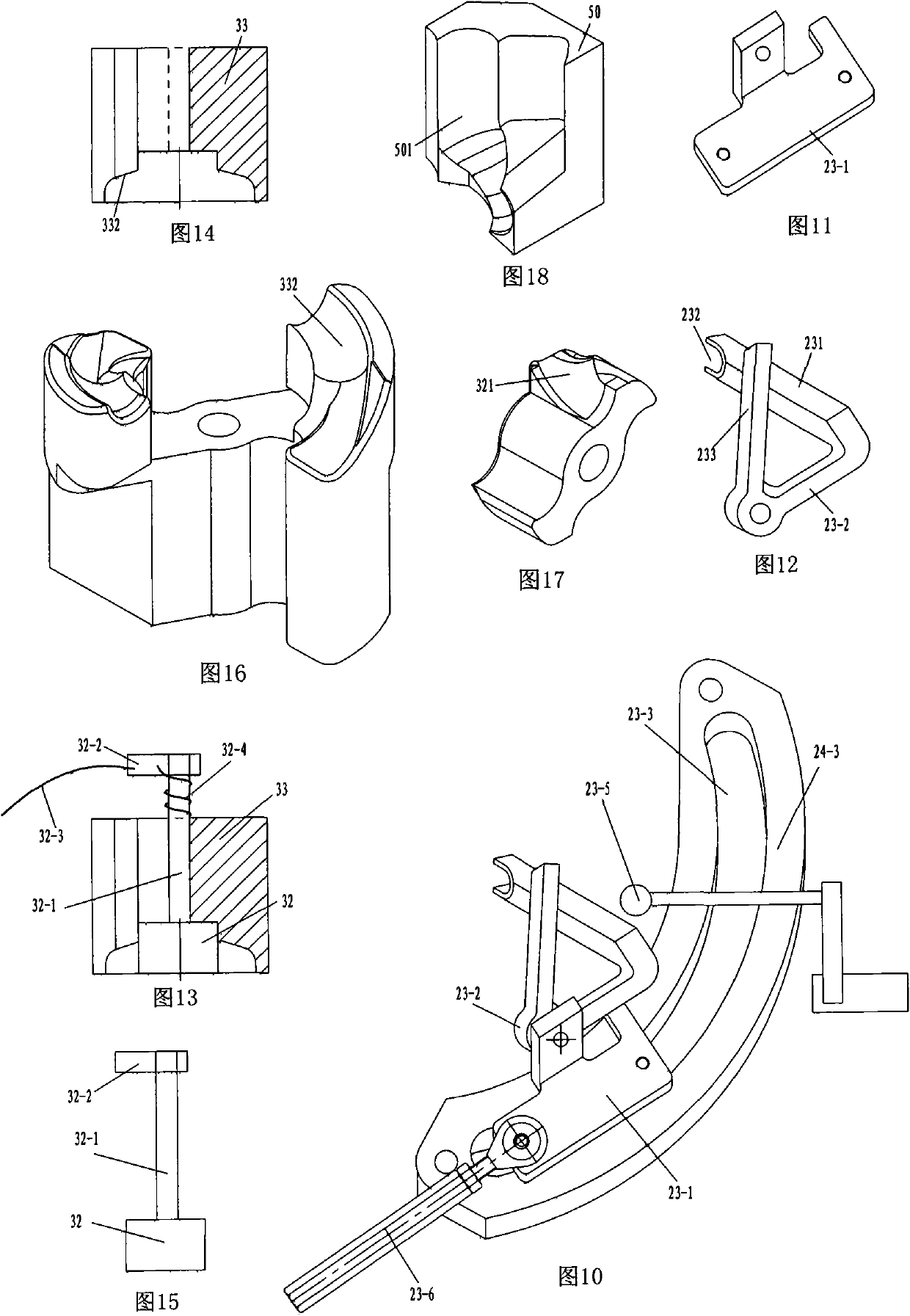

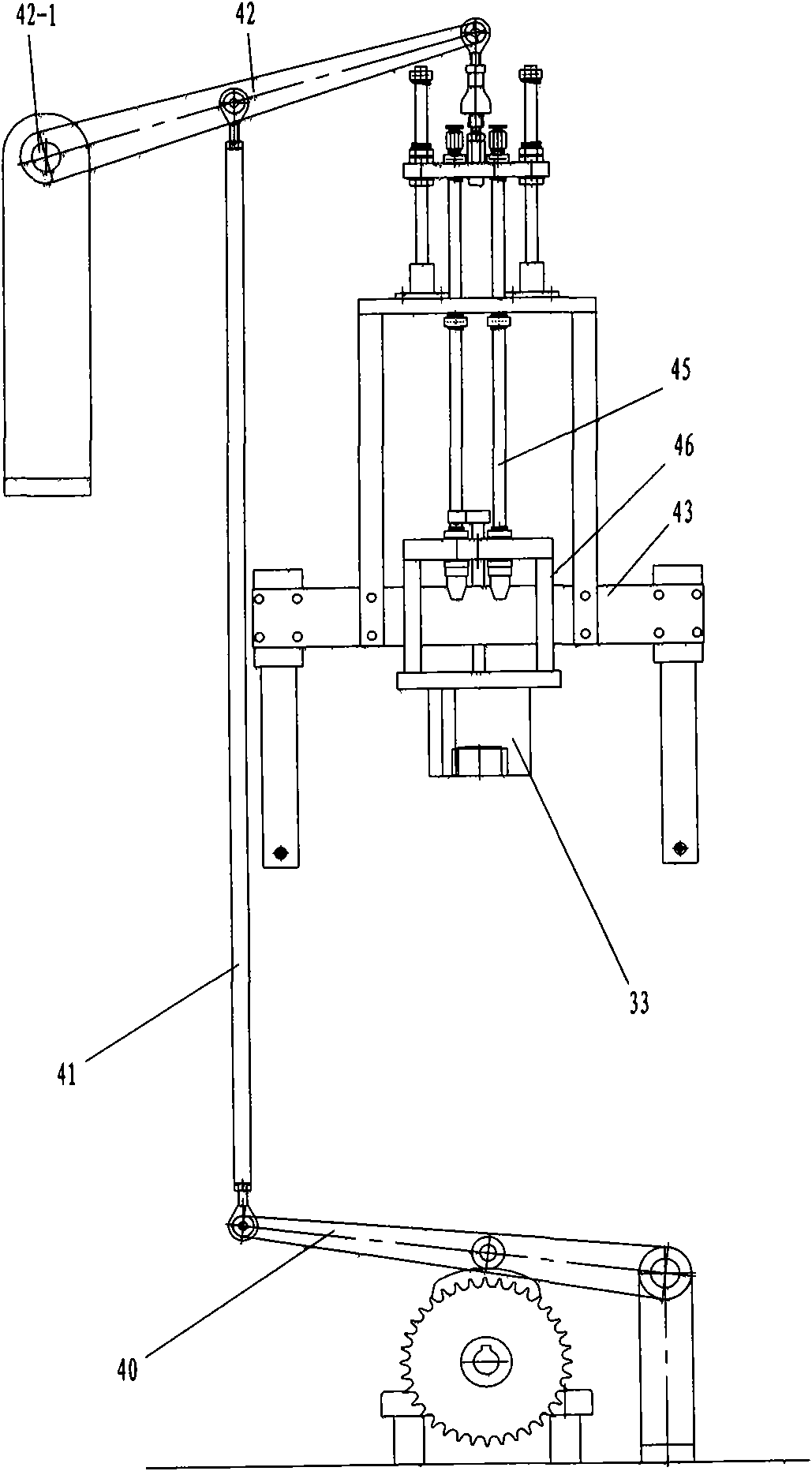

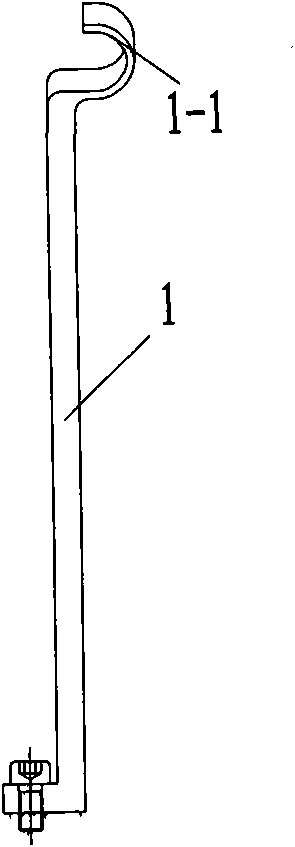

[0045] As shown in the figure, in the spiral lamp tube bending machine, a strip-shaped frame 20 is arranged, and the conveyor belt driven by the gap mechanism is positioned end-to-end between the head and the tail of the machine. The positioning molds for processing the lamp tubes are evenly arranged in a line on the conveyor belt 6, and the loading and unloading lamp tube station 2, oven 3, heating torch 21 and foot bending station 5 are also arranged in sequence from the head to the tail of the machine;

[0046]The foot-bending station is provided with a bending-foot mechanism driven by a driving mechanism to bend the softened pin according to the set requirements; the driving mechanism adopts a conventional crank-link mechanism.

[0047] The conveyor belt is a chain arranged at the center of the frame, and the chain is wrapped around four chain wheels 6-1 from the head to the tail and connected end to end to form a circle; the driving wheel in the chain wheel is driven by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com