Preparation method of nano copper film-based copper nano structure

A nano-copper and copper nano-technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems that have not been found in relevant reports, and achieve the effect of simple annealing treatment method and clear mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

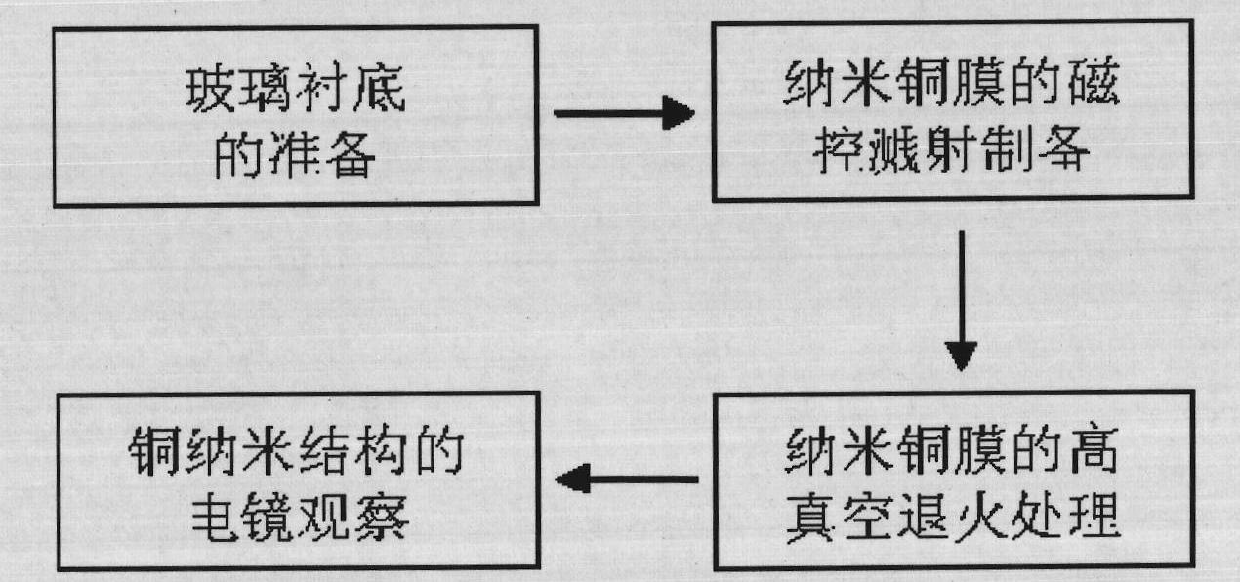

Method used

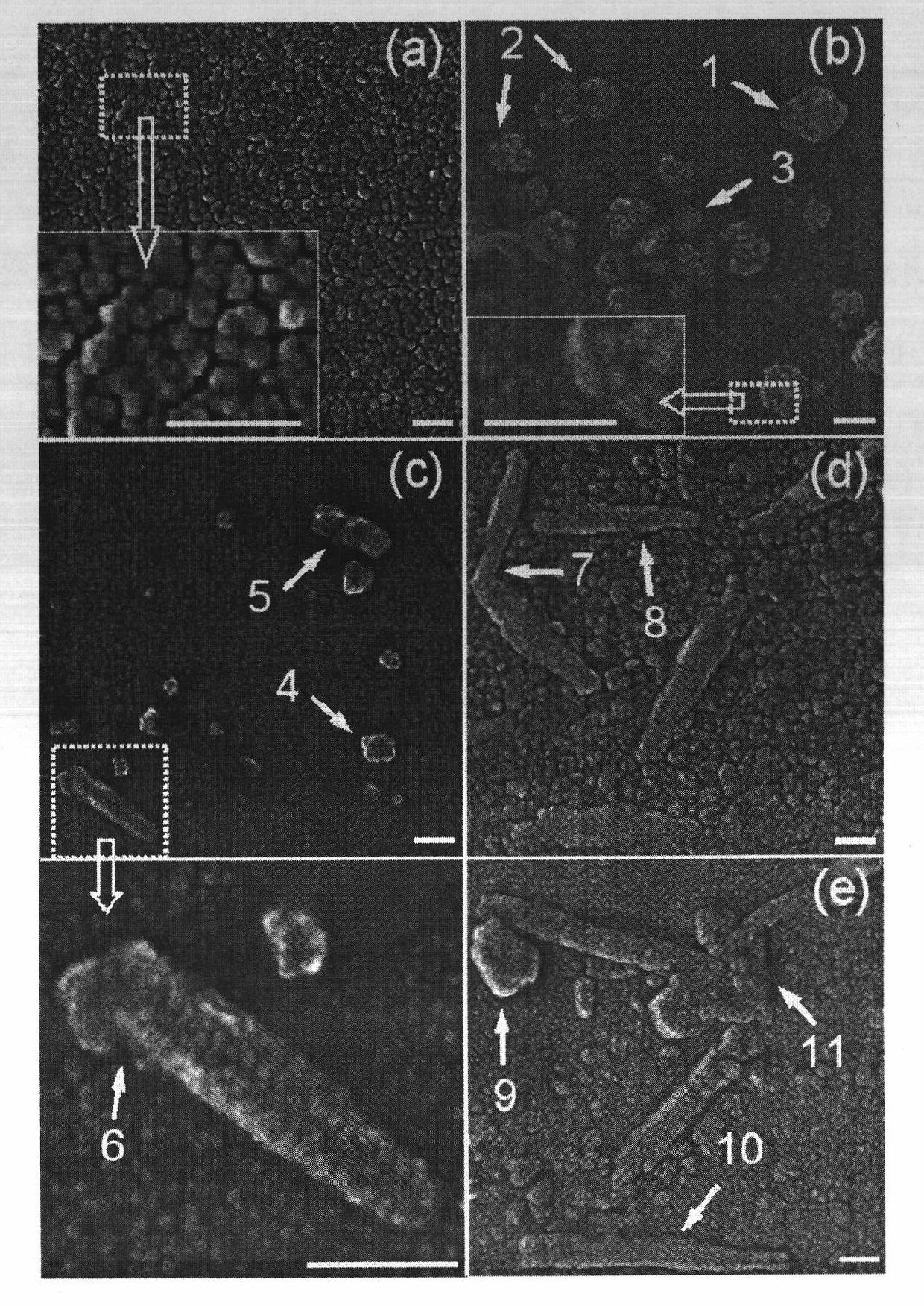

Image

Examples

Embodiment 1

[0020] 1) Preparation of the glass substrate: take a few microscope slides and place them in alcohol for ultrasonic cleaning for 15 minutes, then rinse them repeatedly with deionized water, and then use an electric fan to place the slides front and back at a grazing angle of about 20°. Dry the residual moisture on both sides in one direction, and finally place the glass slide in an oven at 100°C for 15 minutes, and select the cleanest glass slide as the substrate for depositing the nano-copper film;

[0021] 2) Preparation of nano-copper film: place the prepared glass substrate in a magnetron sputtering chamber, install a copper target with a purity of 99.99%, and vacuum the chamber to 5.0×10 -4 Pa, then pass through high-purity Ar gas with a flow rate of 20sccm and a purity of 99.999%, maintain the chamber pressure at 0.5Pa, adjust the sample disk speed to 2r / min, adjust the DC sputtering power to 100W, and remove the baffle at room temperature Start to deposit the copper fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com