Pipe belt type wind turbine air cooler

A wind turbine, tube-belt technology, applied to wind turbine components, wind engines, wind power generation, etc., can solve the problems of shortening the service life of the motor, the decline of the heat dissipation performance of the air cooler, and the damage of the wind turbine, and achieves enhanced replacement. Heat, the effect of increasing air turbulence on the hot side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

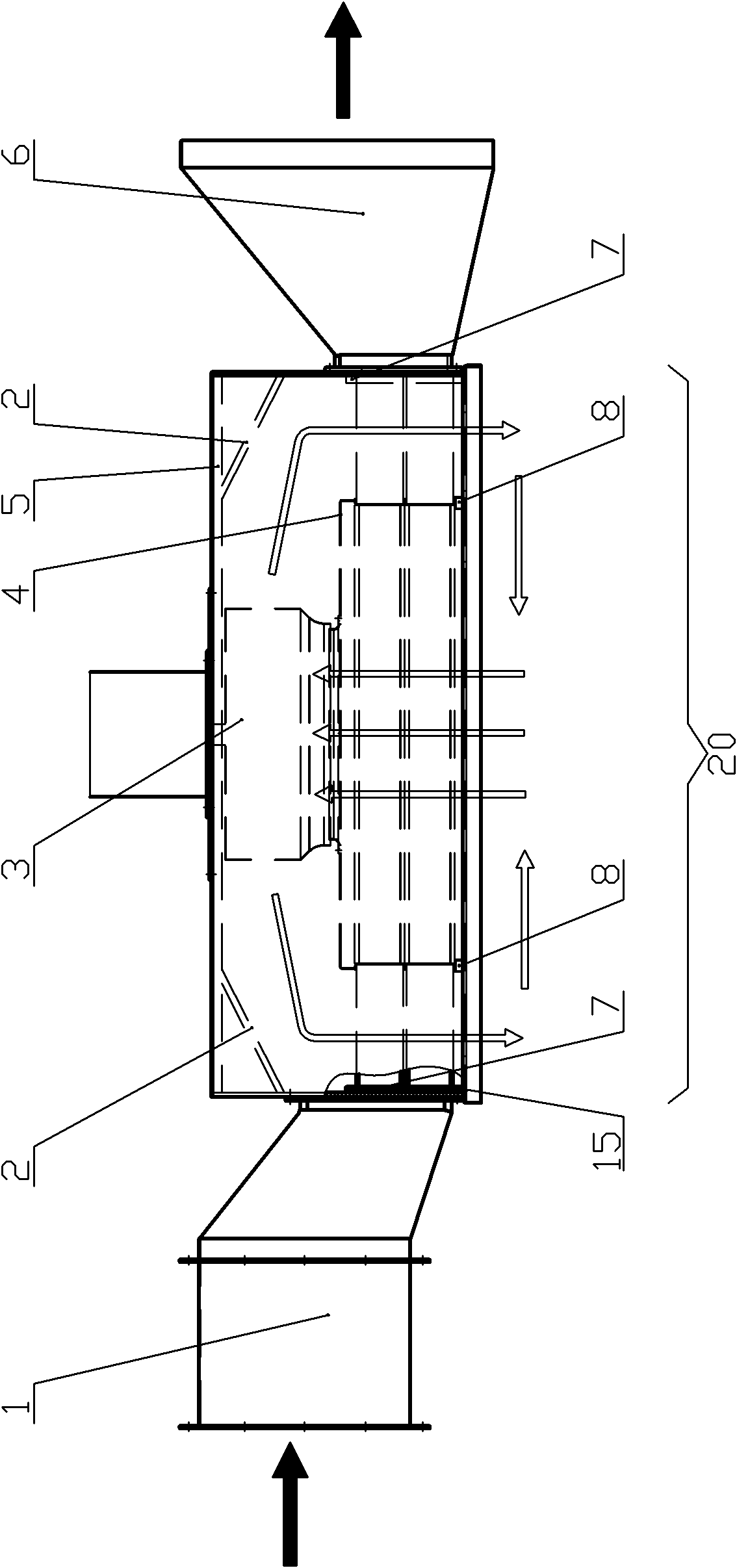

[0023] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-7 :

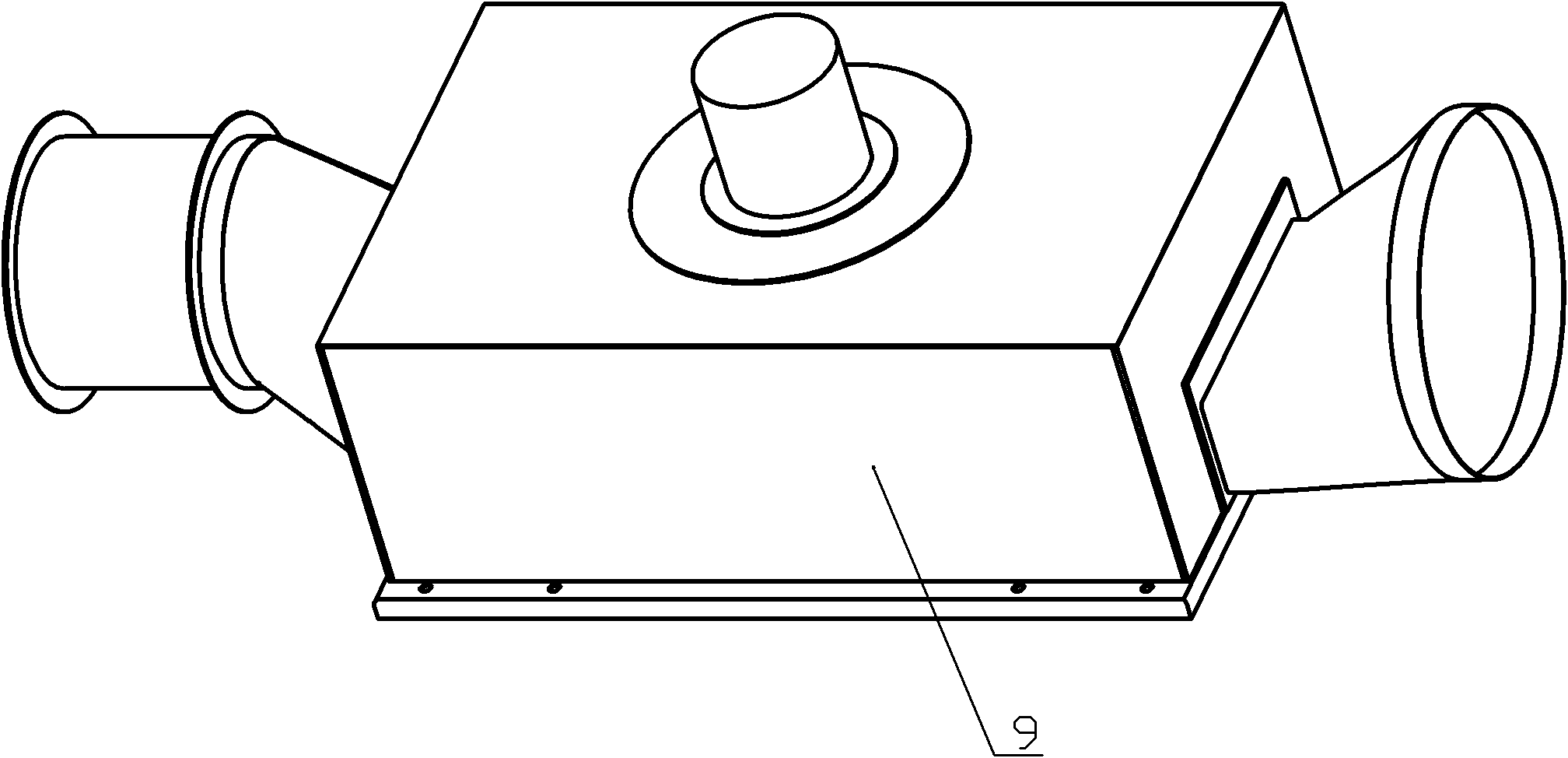

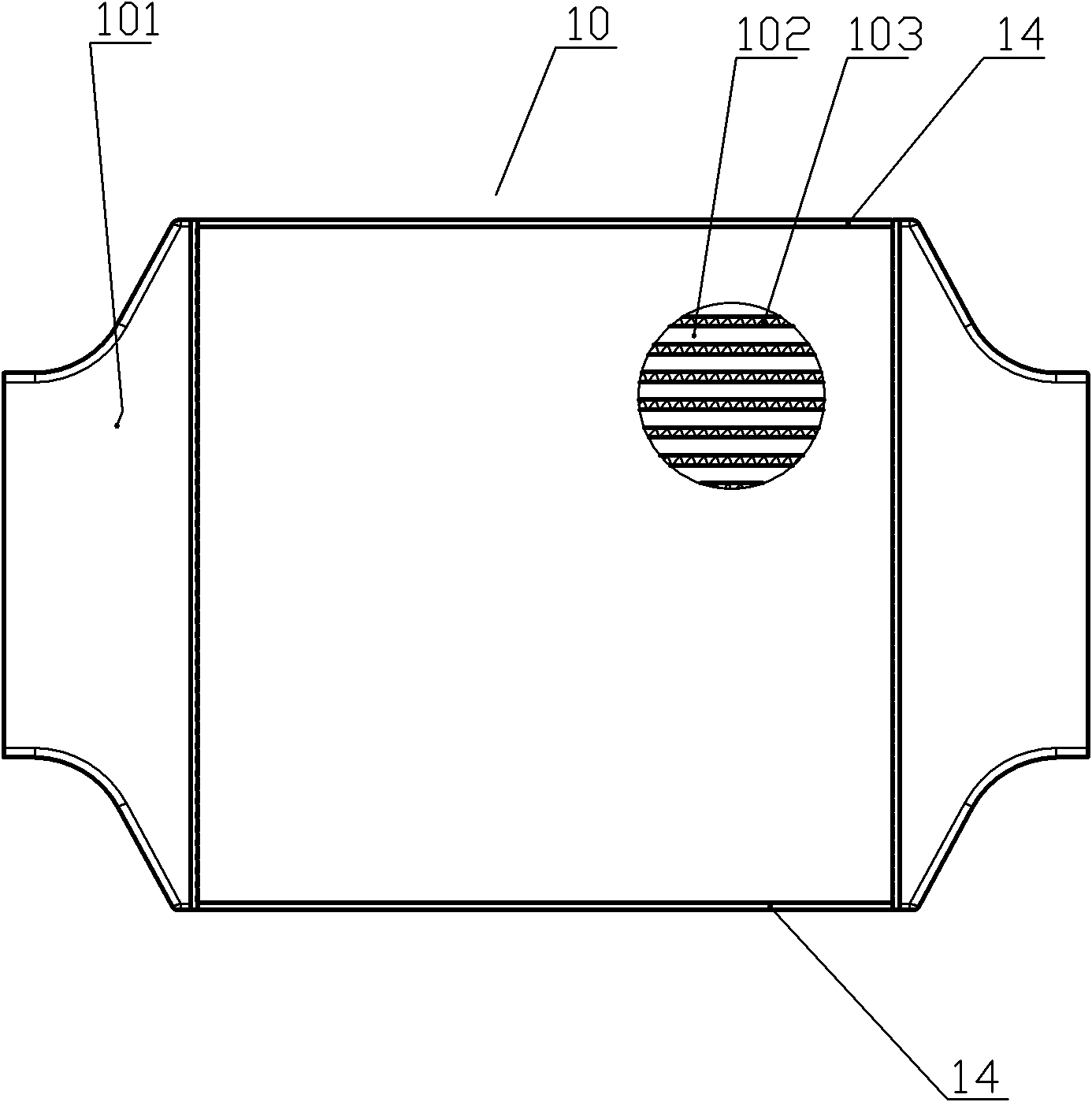

[0024] The tube-belt air-to-air cooler for wind turbines is fixed with a cold-side drainage fan 1 at one end of the cooler 20, with an air outlet 6 fixed at the other end, with a hot-air inlet in the middle, and hot-air outlets on both sides of the hot-air inlet. At the air outlet, several heat dissipation cores 10 are fixed in the cooler shell 9, and a hot side circulation fan 3 is fixed in the center of the uppermost side of the heat dissipation core 10. Several flat tubes 102 are arranged in the heat dissipation core 10 to form a flat tube bundle. A heat dissipation belt 103 is arranged between the flat tubes 102, a main board 104 is fixed at both ends of the flat tube bundle, and an air chamber 101 is fixed on the main board 104. Unicom, the other end communicates with the air exhaust port 6, the heat dissipation strips 103 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com