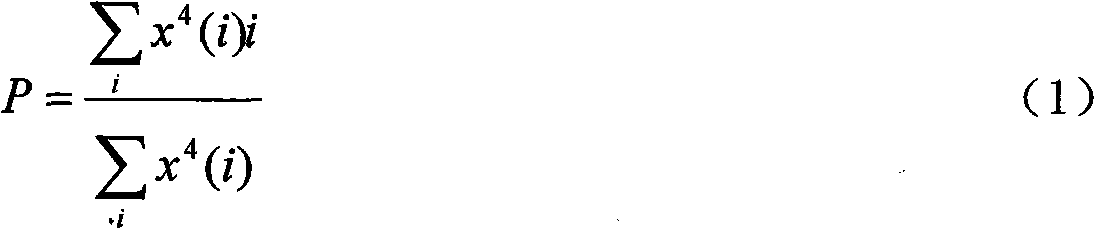

Microstructure topography test system and method based on white light phase shift interferometry

A technology of phase-shift interference and testing system, which is applied in the field of microstructure topography testing, can solve problems such as overshoot and lower measurement resolution, achieve high measurement efficiency, avoid unwrapping process, and expand the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

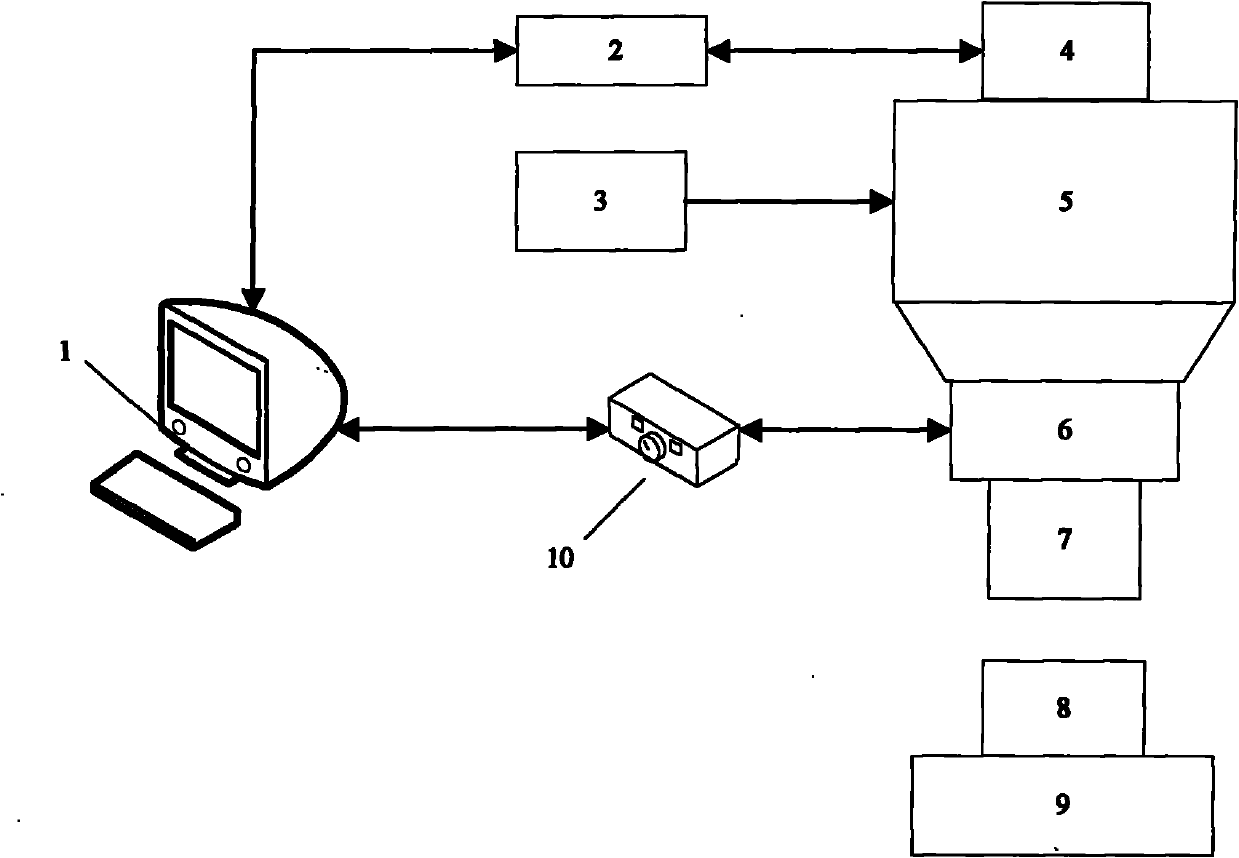

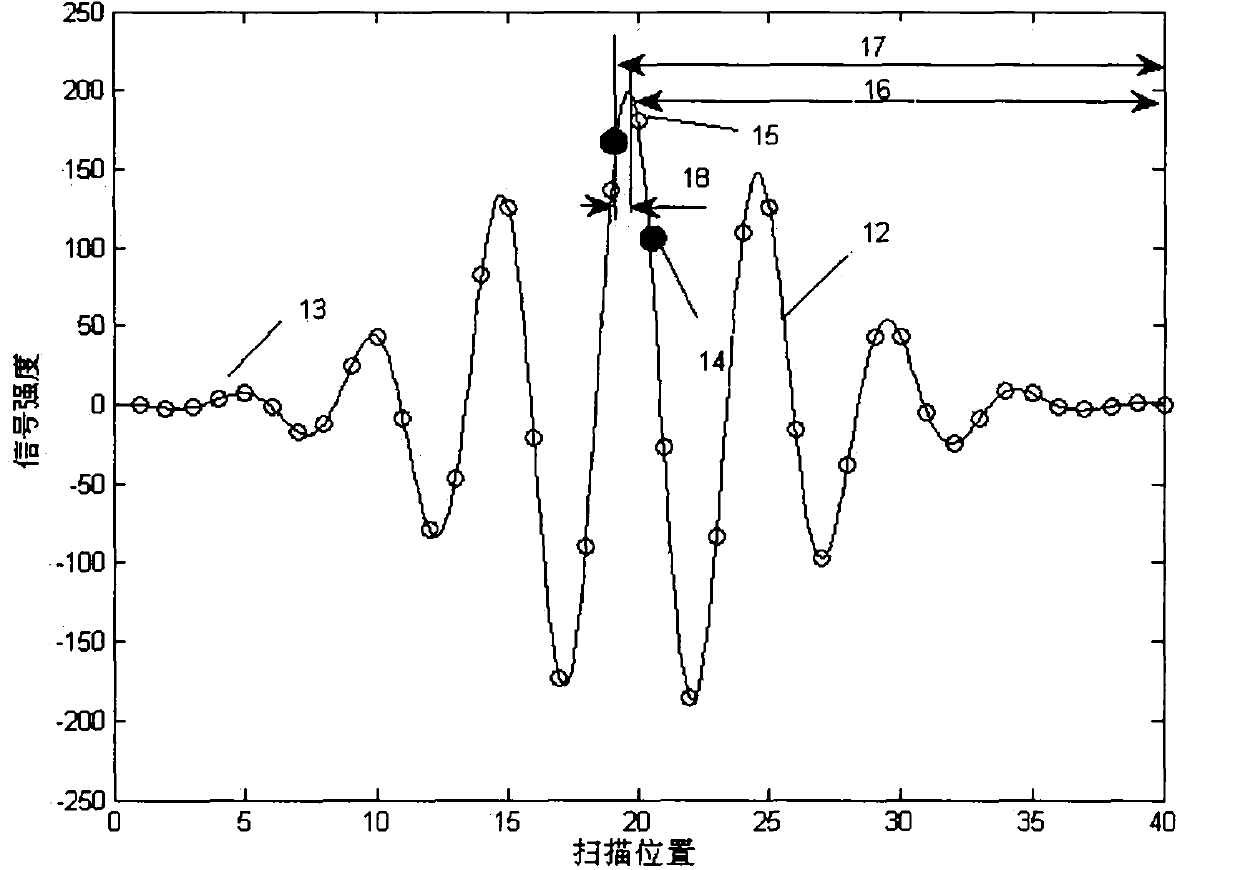

[0033] The microstructure morphology test system and test method based on white light phase shift interferometry of the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

[0034] The microstructure topography testing system based on white light phase-shift interferometry of the present invention comprises a digital CCD camera 4, a micro-optical system 5, a piezoelectric ceramic (PZT) phase shifter 6, an interference objective lens 7 and a display device arranged in sequence. The micro-optical system 5 provides the white light source 3 of the light source, the piezoelectric ceramic (PZT) driver 10 connected to the piezoelectric ceramic (PZT) phase shifter 6, and a PC 1, and the PC 1 passes through the image acquisition card 2 is connected with the digital CCD camera 4, and the PC 1 is also connected with the piezoelectric ceramic (PZT) driver 10 through the image acquisition card 2, and the input end of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com