N-type field effect transistor, metal gate and manufacturing method thereof

A technology of field effect transistors and metal gates, which is applied in the field of semiconductor components with metal gates, can solve problems such as component failure and increase component instability, and achieve the effect of low leakage paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Various embodiments of the present invention will be described below. In various examples in this specification, repeated element symbols may appear to simplify the description, but this does not mean that there is any specific relationship between the various embodiments and / or the drawings. . Furthermore, when it is mentioned that a certain element is located "on" or "over" another element, it may mean that the two elements are in direct contact or that other elements or film layers are interposed therebetween. In order to simplify the drawings and highlight the features of the present invention, various components may not be drawn in actual scale.

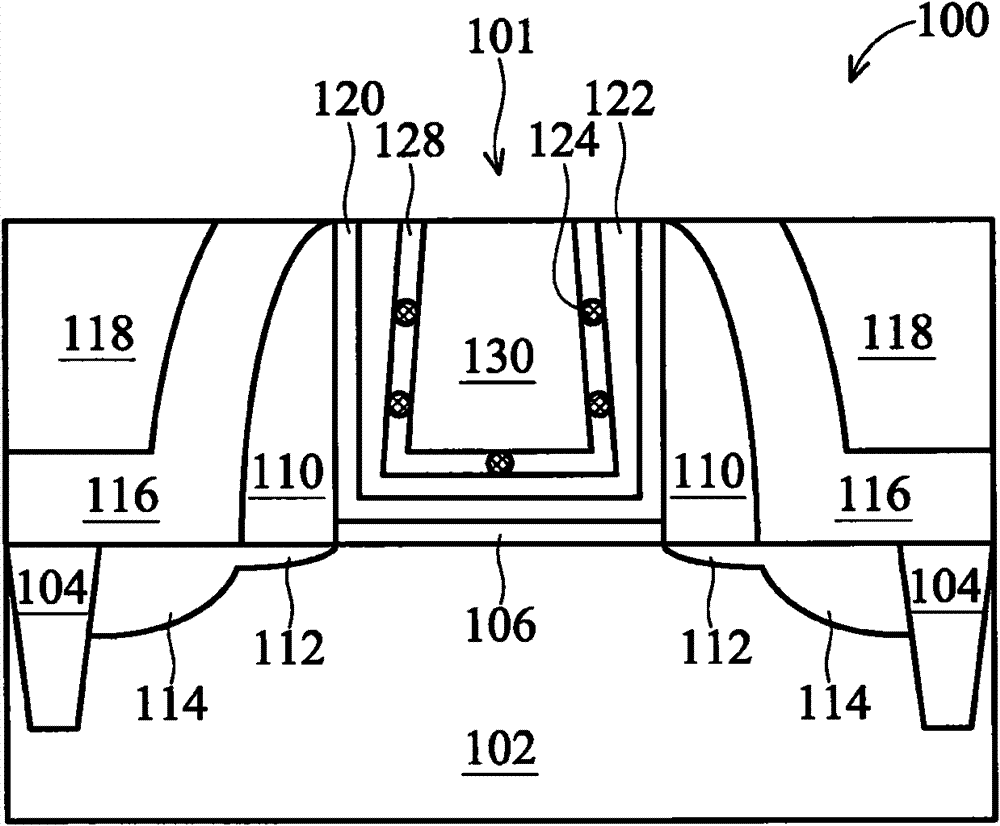

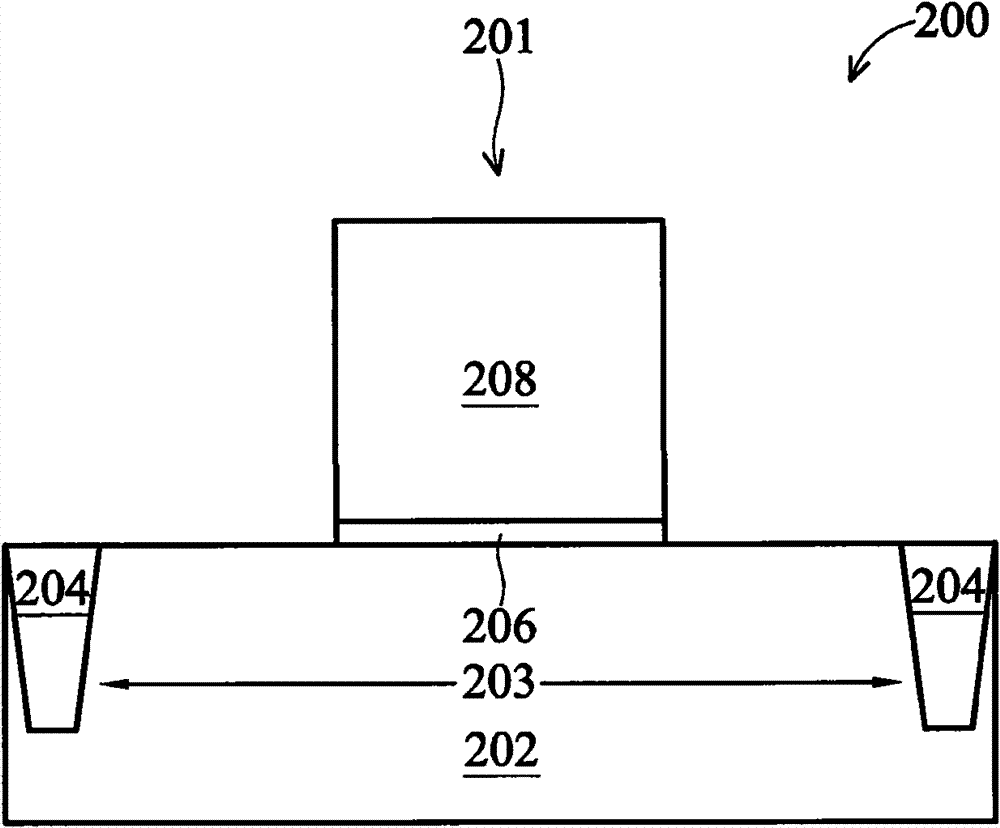

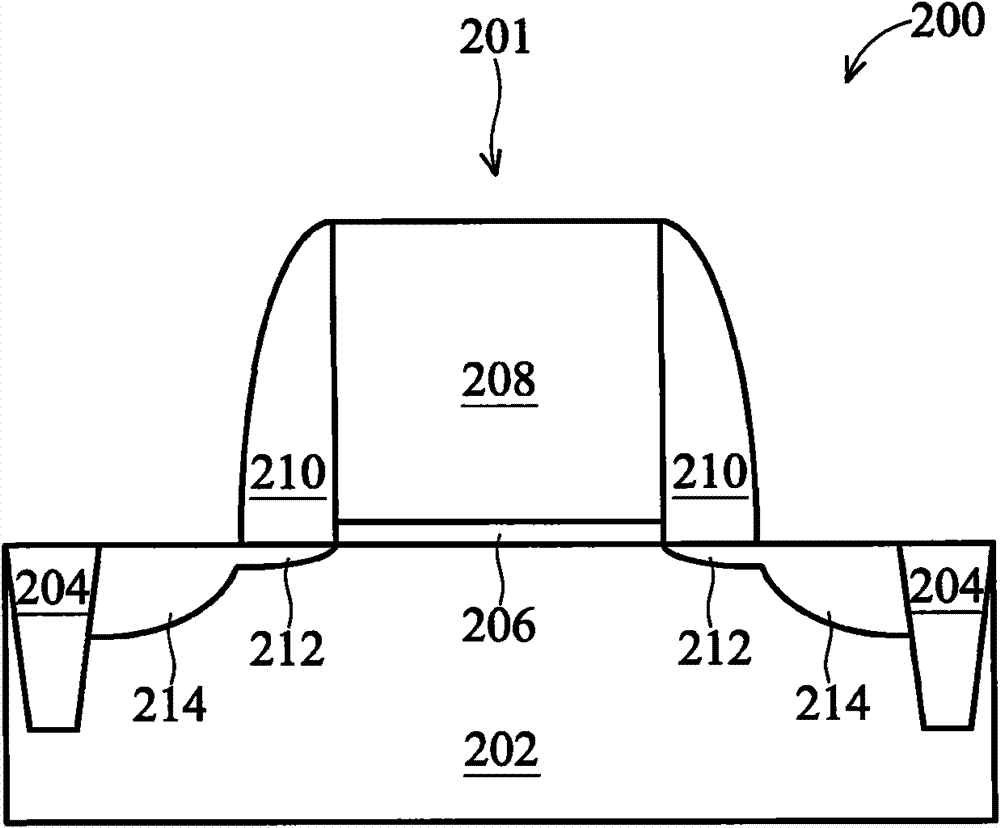

[0034] Please refer to Figure 2A ~ Figure 3 , the semiconductor device 200 and the method 300 will be described together below. Figure 2A ~ Figure 2I A series of cross-sectional views are used to illustrate various stages of the fabrication process of the metal gate structure according to the embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com