Shield gate mosfet and method for fabricating the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example 1

SIMULATION EXPERIMENTAL EXAMPLE 1

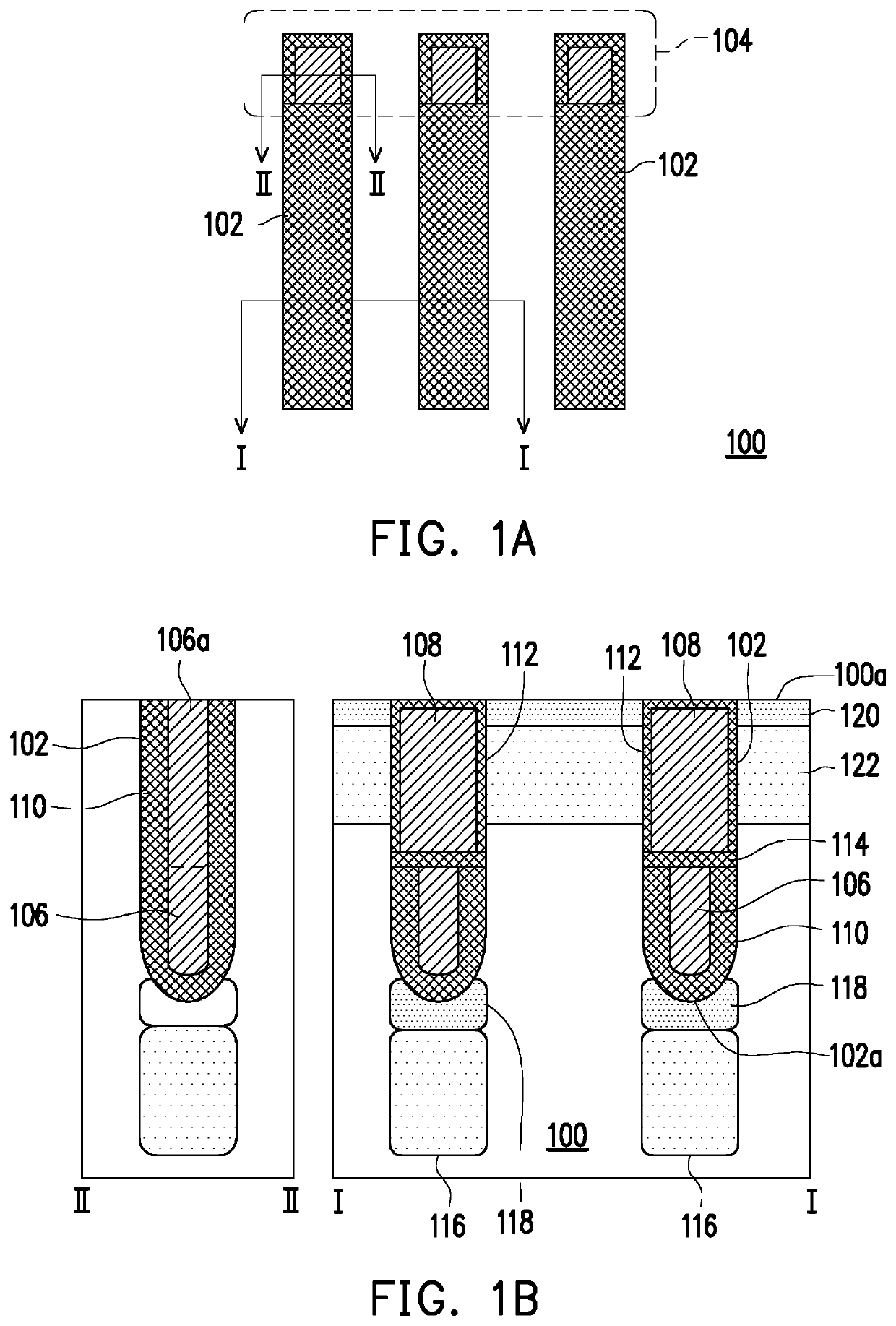

[0054]The simulated structure is the shield gate MOSFET (EPI resistance is 0.35 Ω·cm / thickness 4 μm) shown in FIG. 1B, and a 150 V DG breakdown voltage is simulated, wherein the first doped region is P type, and the second doped region is N type, the doping dosage of the first doped region is a variable, and the depth is about 0.5 μm to 1.5 μm. The depth of the second doped region is about 0.5 μm or less and the doping dosage is 2E11 cm−2, which are shown in FIG. 4 together with the simulation results (BVDss).

[0055]As may be seen from FIG. 4, the structure of the disclosure has a breakdown voltage higher than 152 V; when the doping dosage of the first doped region is 4E12 cm−2 to 5E12 cm−2, the breakdown voltage thereof is higher than 160 V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com