Load-bearing conductive signalling non-extension cable of slided intelligent clinometer

A sliding type, inclinometer technology, applied in the field of inclinometers, can solve the problems of measuring point depth positioning error, affecting the accuracy of measurement results, large diameter, etc., and achieve the effects of low deformation characteristics, light weight and small diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

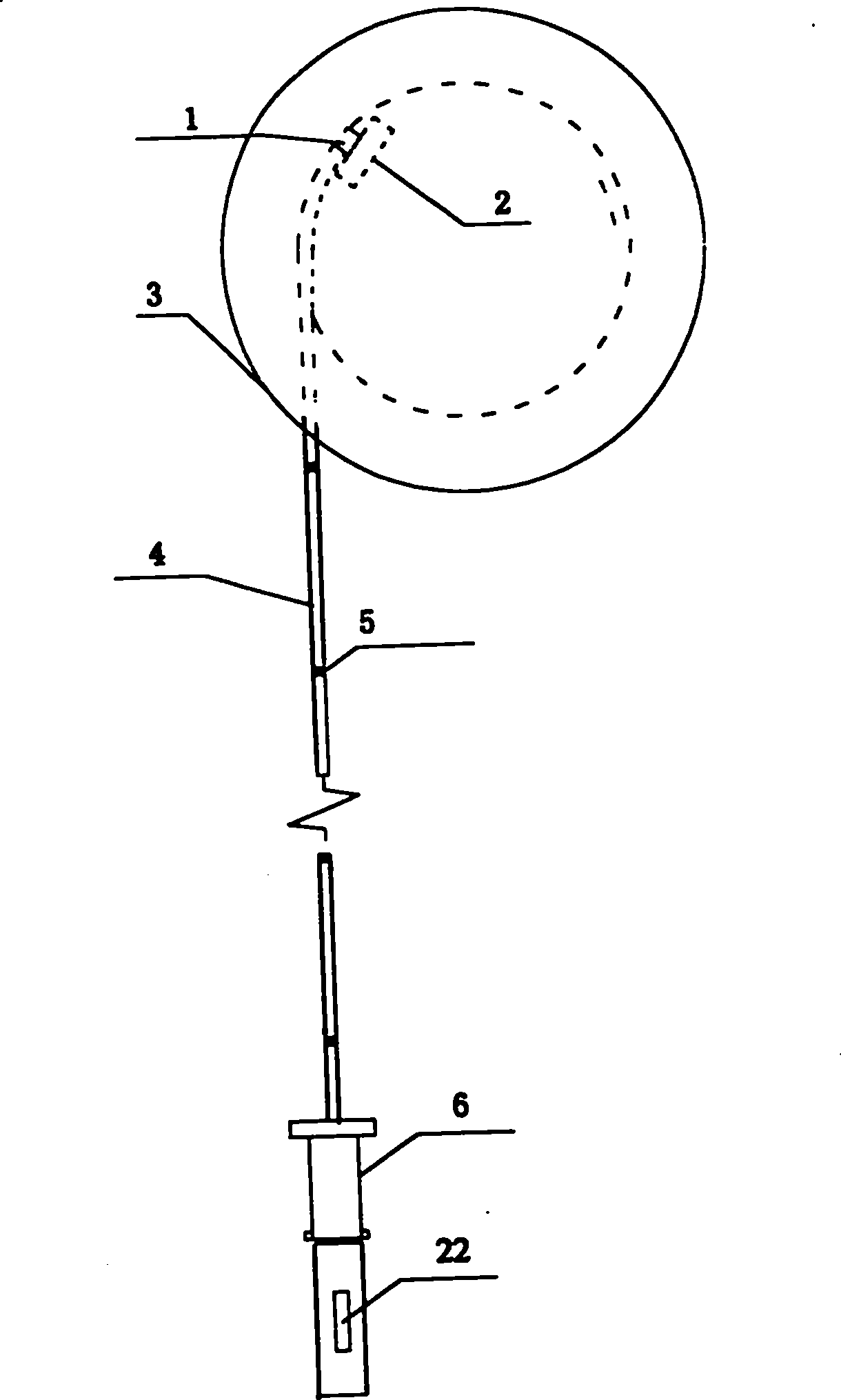

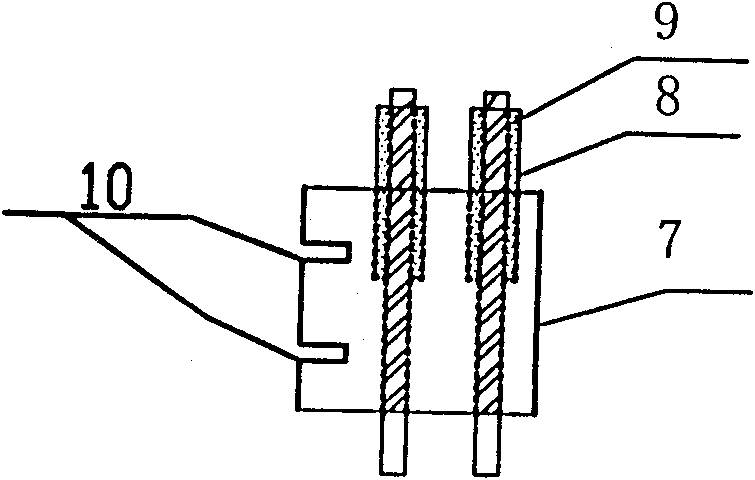

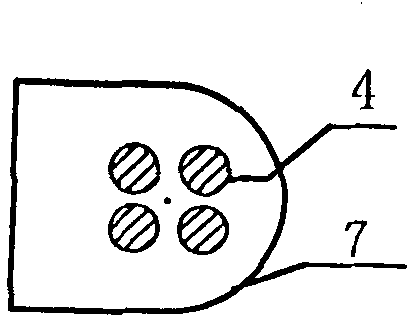

[0013] Control attached Figure 1-7 , its structure is to include cable beginning connector 1, cable main controller 2, integrated inductive winding machine 3, cable 4, tinfoil ring 5, probe connector 6, wherein cable beginning connector 1, cable main controller 2, Integrated inductive winding machine 3, cable 4, tinfoil ring 5, probe connector 6, wherein the cable start connector 1 and cable main controller 2 are fixed on the inner wall of the winding wheel of the integrated inductive winding machine, and the cable 4 The core wire at the start end is anchored on the cable start connector 1, and the lead-out line of the cable start connector 1 is connected with the signal input line of the cable master controller. Tin foil rings 5 are arranged at equal intervals on the top, the cables 4 and tin foil rings 5 are integrally plastic-sealed in the plastic sealing layer 14, the cables 4 are coiled and integrated with the inductive winding machine 3, and then connected to the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com