Method for producing electroplated board edge of circuit board

A production method and circuit board technology, applied in electrical components, printed circuits, printed circuit manufacturing, etc., can solve problems such as the inability to effectively control static electricity and anti-static problems of electronic components, and achieve metallization, flatness, and processing technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with description of drawings and specific embodiments:

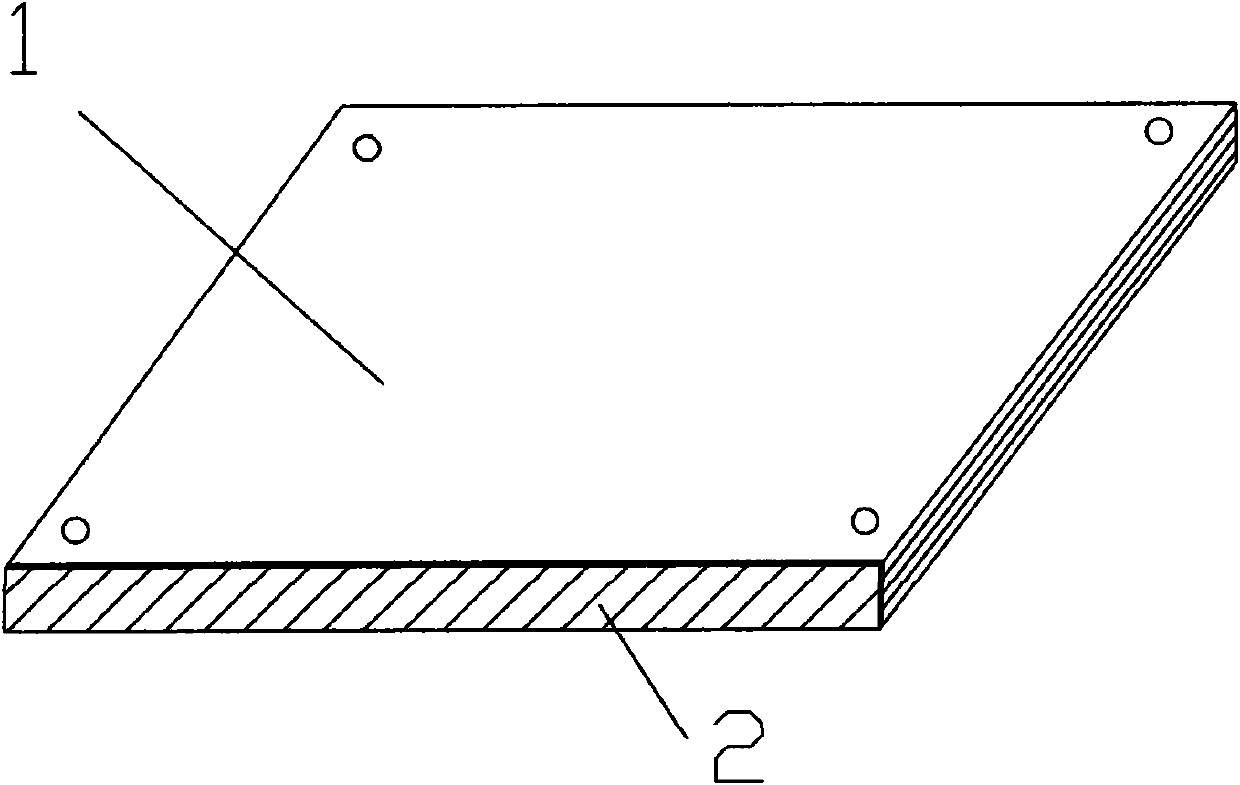

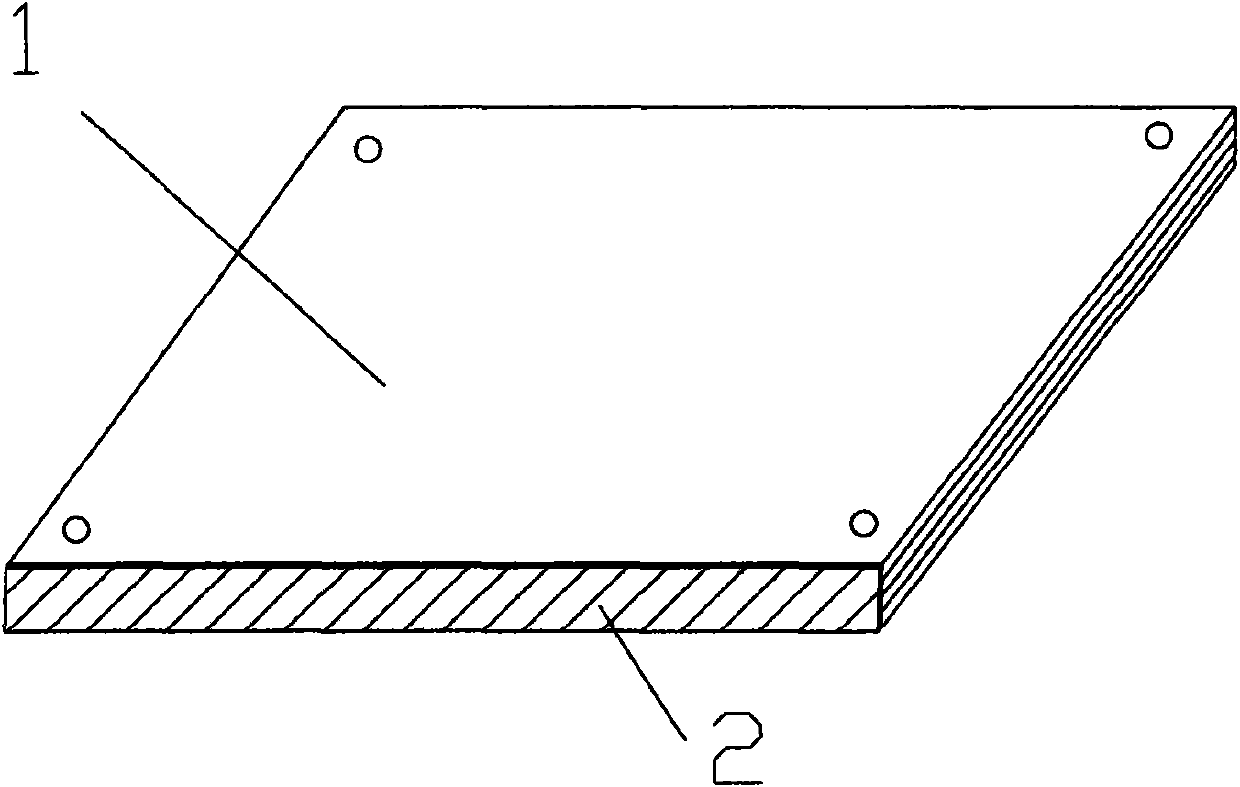

[0048] Such as figure 1 The illustrated circuit board of the present invention includes a board body 1 , and a copper plating layer 2 for electrostatic discharge protection lines is provided on at least one side of the board body 1 .

[0049] The production method of circuit board electroplating board edge of the present invention comprises the following process steps:

[0050] 1) Pre-process treatment

[0051] Mainly include: ①incoming material inspection; ②cutting CCL; ③exposure, development; ④pressing plate; ⑤drilling; ⑥board washing, drying and other processes;

[0052] The specific method is: use an automatic cutting machine to cut the large material into the most suitable small material for the copper clad laminate that has passed the inspection; paste a layer of photosensitive material (dry film) on the surface of the copper clad laminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com