High metal content molecular sieves and their manufacture

A molecular sieve and metal technology, applied in the field of high metal content molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

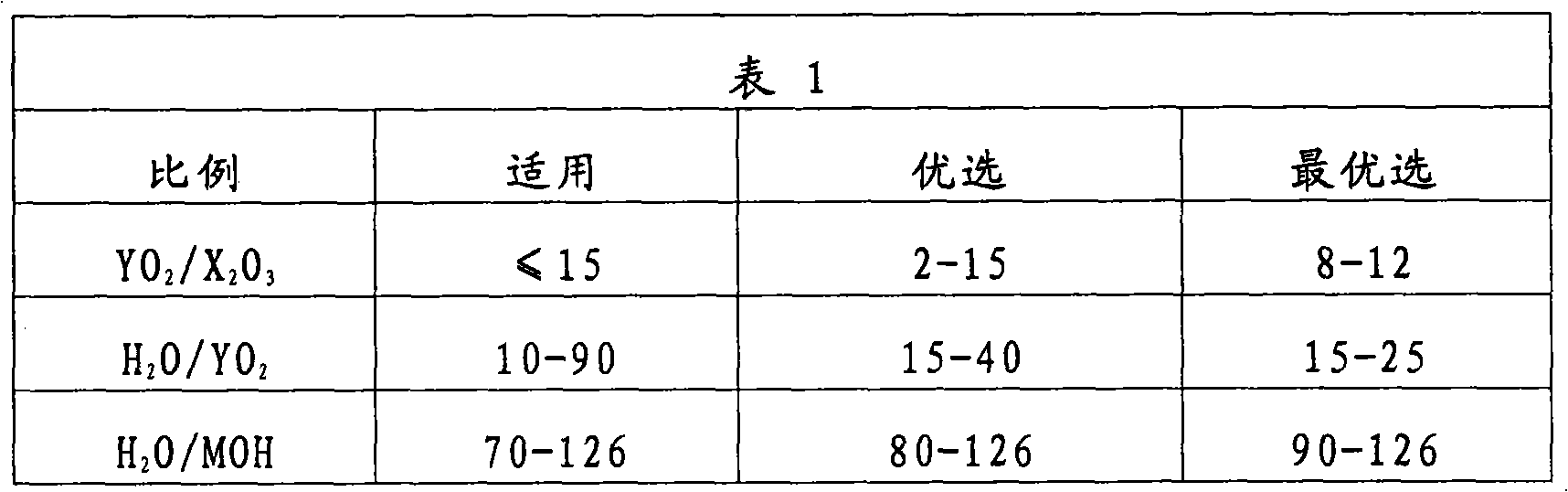

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1 uses n-propylamine and seed synthesis ZSM-5

[0070] Prepared by 250g deionized water, 10g 50% NaOH aqueous solution, 16g sodium aluminate (25.5% alumina and 19.5% Na 2 O), 8g n-propylamine, 3g ZSM-5 seeds and 75g Reaction (synthesis) mixture of 90 amorphous silica-alumina (15:1 molar silica / alumina) (supplied by Sasol / Condea). H of the reaction mixture 2 The O / NaOH molar ratio was 125.6. The reaction mixture was injected into a Parr autoclave and crystallized at 155°C (310°F) and a stirring rate of 200 RPM for 27 hours.

[0071] The solid product was isolated from the resulting product mixture by filtration, washed with deionized water and dried at 110°C. The product mixture contained 78.7% solids. The solid product was analyzed by X-ray diffraction and scanning electron microscopy (SEM), and it was found to be highly crystalline small crystal ZSM-5 (MFI structure type at this time), whose SiO 2 / Al 2 o 3 The molar ratio is 9:1.

[0072]The ZSM-5...

Embodiment 2

[0073] Embodiment 2 uses n-propylamine and seed synthesis ZSM-5

[0074] Prepared by 250g deionized water, 14.5g 50% NaOH aqueous solution, 6g sodium aluminate (25.5% alumina and 19.5% Na 2 O), 8g n-propylamine, 3g ZSM-5 seeds and 75g Reaction (synthesis) mixture of 90 amorphous silica-alumina (15:1 molar silica / alumina) (supplied by Sasol / Condea). H of the reaction mixture 2 The O / NaOH molar ratio was 91.5. The reaction mixture was injected into a Parr autoclave and crystallized at 155°C (310°F) and a stirring rate of 200 RPM for 24 hours.

[0075] The solid product was isolated from the resulting product mixture by filtration, washed with deionized water and dried at 110°C. The product mixture contained 86.9% solids. The solid product was analyzed by X-ray diffraction and scanning electron microscopy (SEM), and it was found to be highly crystalline small crystal ZSM-5 (MFI structure type at this time), whose SiO 2 / Al 2 o 3 The molar ratio is 11:1.

[0076] The ZSM...

Embodiment 3

[0077] Example 3 Synthesis of ZSM-5 using n-Propylamine and Seeds

[0078] Prepared by 125g deionized water, 10g 50% NaOH aqueous solution, 3g sodium aluminate (25.5% alumina and 19.5% Na 2 (0), 8g n-propylamine, 2g ZSM-5 seeds and 37.5g Reaction (synthesis) mixture of 90 amorphous silica-alumina (15:1 molar silica / alumina) (supplied by Sasol / Condea). H of the reaction mixture 2 The O / NaOH molar ratio was 71.0. The reaction mixture was injected into a Parr autoclave and crystallized at 155°C (310°F) and a stirring rate of 200 RPM for 22 hours.

[0079] The solid product was isolated from the resulting product mixture by filtration, washed with deionized water and dried at 110°C. The solid product was analyzed by X-ray diffraction and scanning electron microscopy (SEM), and it was found to be highly crystalline small crystal ZSM-5 (MFI structure type at this time), whose SiO 2 / Al 2 o 3 The molar ratio is 12:1.

[0080] The ZSM-5 material was converted to its acid form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com