Vertical biochemical reaction device

A biochemical reaction and vertical technology, applied in fertilization equipment, climate change adaptation, application, etc., can solve the problems of large footprint, difficulty in centralized treatment of odor and fermentation speed, etc., to achieve a smaller footprint and facilitate industrialization and automation Control and realize the effect of dynamic continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

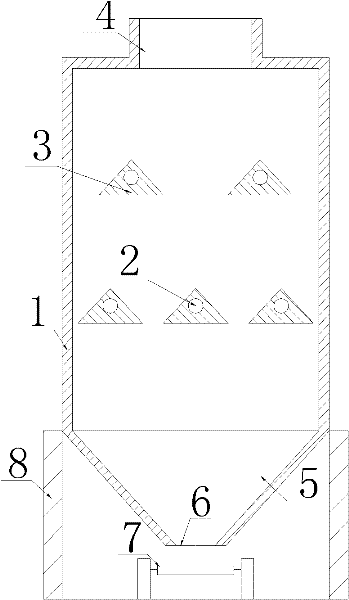

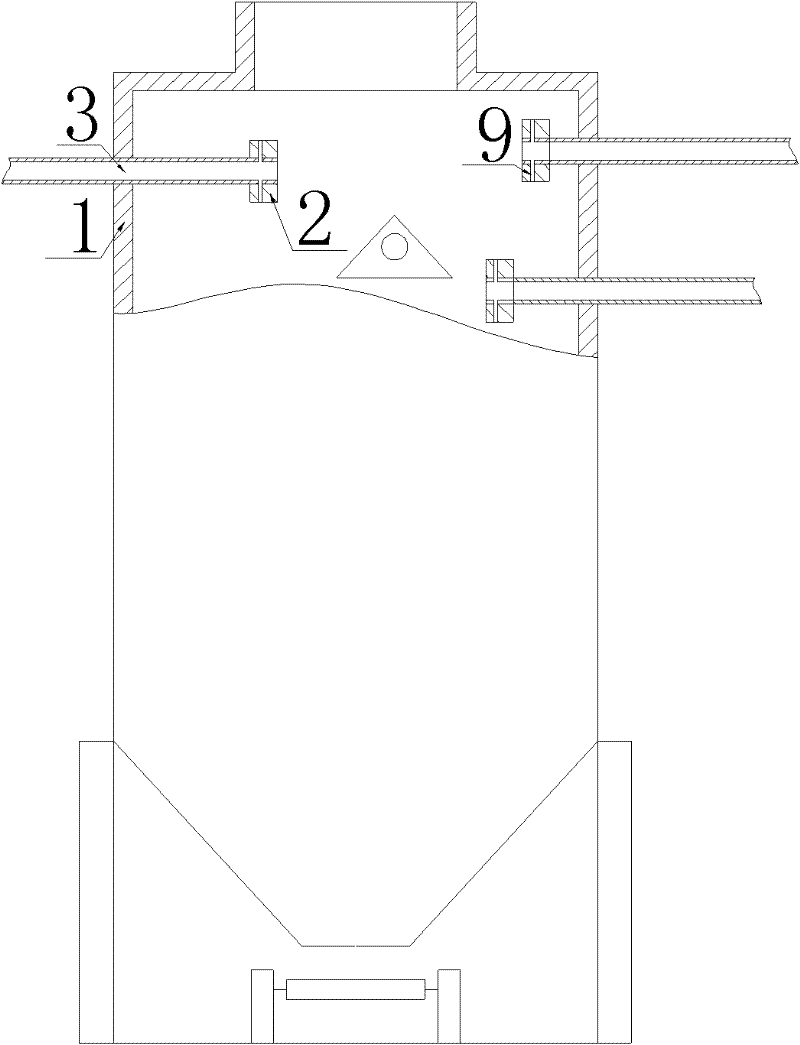

[0015] figure 1 with figure 2 Shown in is the vertical biochemical reaction device of the present invention. The device includes a housing 1, which is fixed on the ground through a bracket 8. The top of the housing 1 is provided with a feeding port 4, the lower part of the housing 1 is connected with a hopper 3, the housing 1 communicates with the hopper 3, the bottom of the hopper 3 is provided with a discharge port 6, and the bottom of the discharge port 6 is provided with a delivery port. Feeding machine 7, feeder 7 is fixed on the ground. Inside the housing 1 is a cavity, such as figure 1 As shown, a plurality of stirrers 2 are fixedly connected in the housing 1, such as figure 1 shown. The agitator 2 is fixed with a ventilation duct 3, and there is always air circulation in the ventilation duct 3. The ventilation duct 3 is fixed on the housing 1, that is, the agitator 2 is fixedly connected with the housing 1 through the ventilation duct 3, and the ventilation duct ...

Embodiment 2

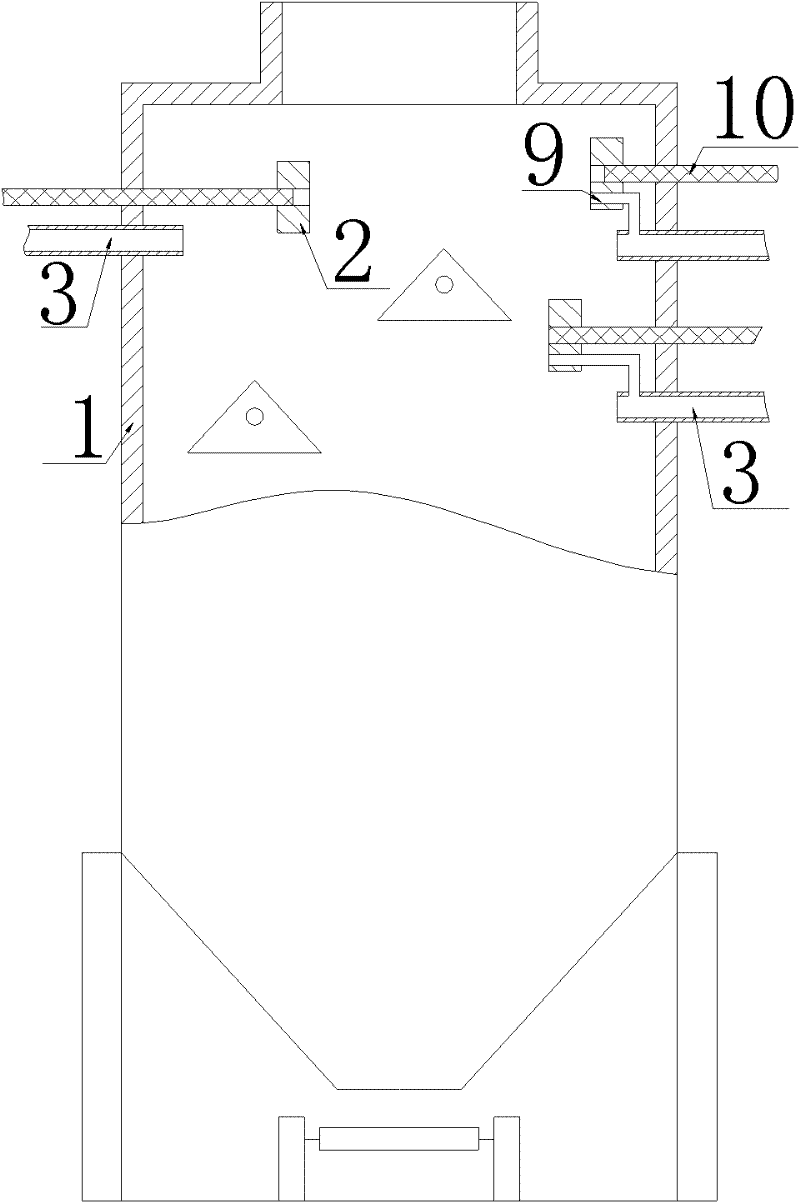

[0019] Such as image 3 As shown, the agitator 2 is fixedly connected to the housing 1 through a connecting shaft 10 , and the agitators 2 are arranged in a staggered manner in the housing 1 . A ventilation duct 3 is fixed on the housing 2, and the ventilation duct 3 is fixedly connected to the housing 1. One end of the ventilation duct 2 communicates with the inside of the housing 1, and the other end communicates with the outside, that is, the ventilation duct 2 connects the inside of the housing 1 with the outside. connected externally. The agitator 2 is provided with an air hole 9 , and the air hole 9 communicates with the ventilation duct 3 .

[0020] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com