Exhaust manifold and exhaust system employing same

An exhaust manifold and exhaust branch pipe technology, which is applied to exhaust devices, mufflers, engine components, etc., can solve problems such as the inability to meet the requirements of high performance and low emission of the engine, and the inability to effectively improve low-speed performance. Low-speed performance, the effect of reducing the level of mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

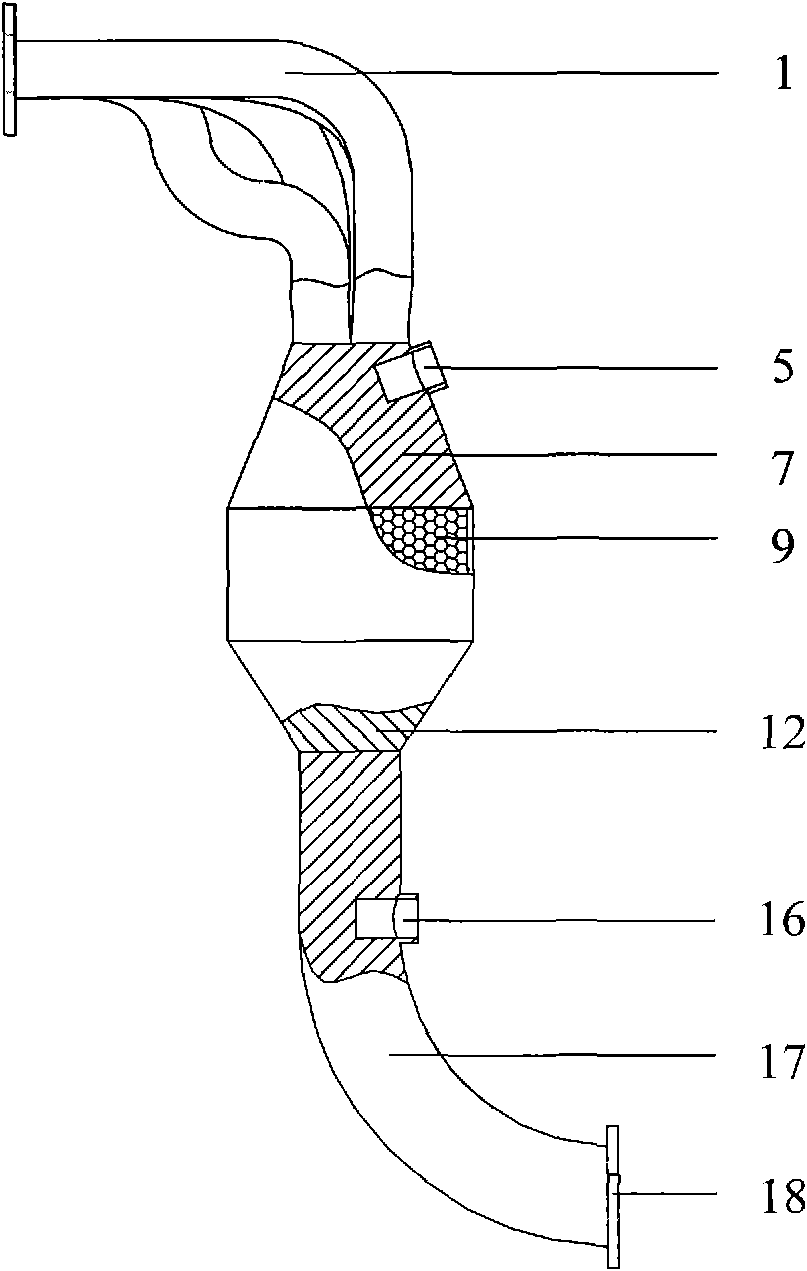

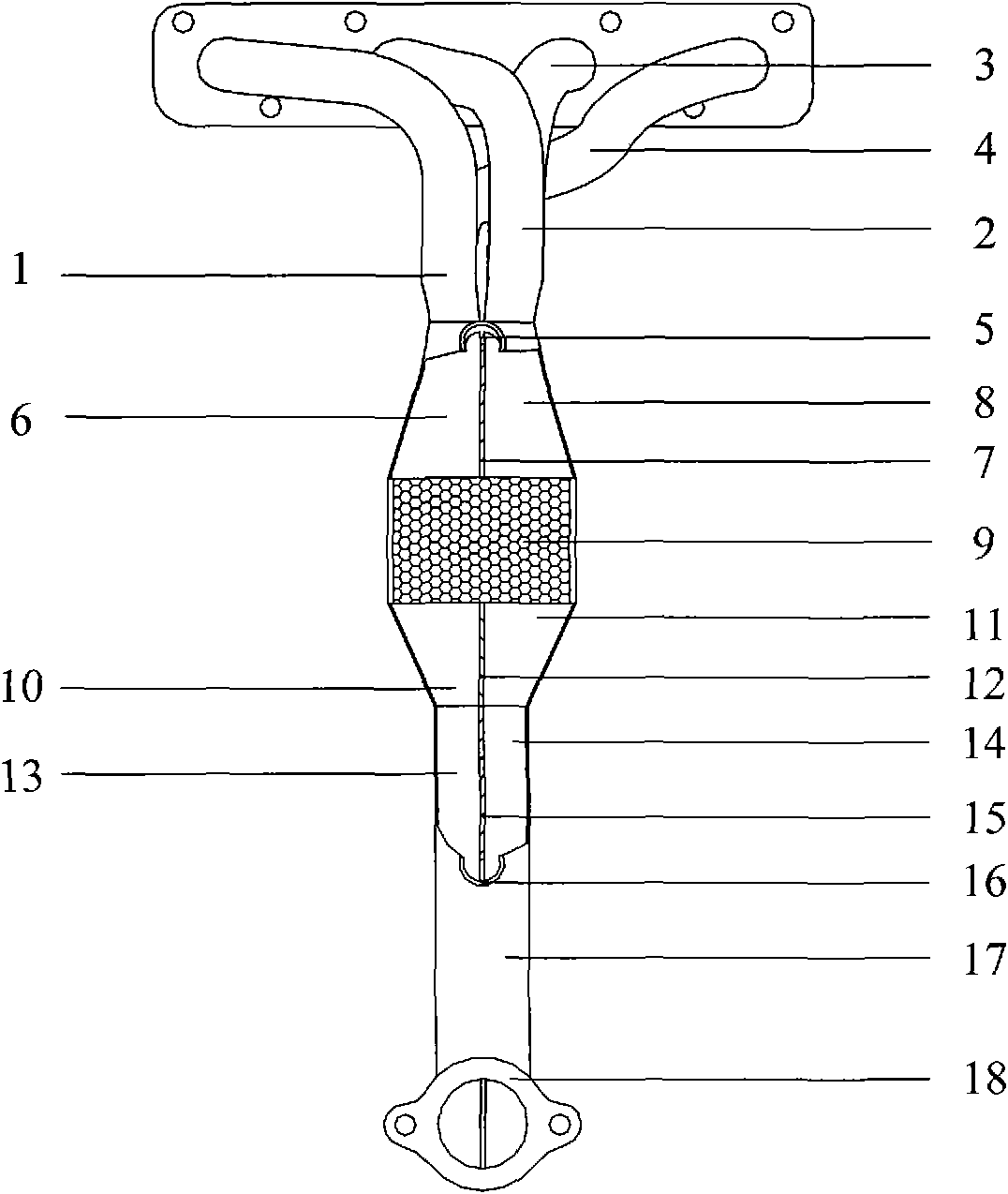

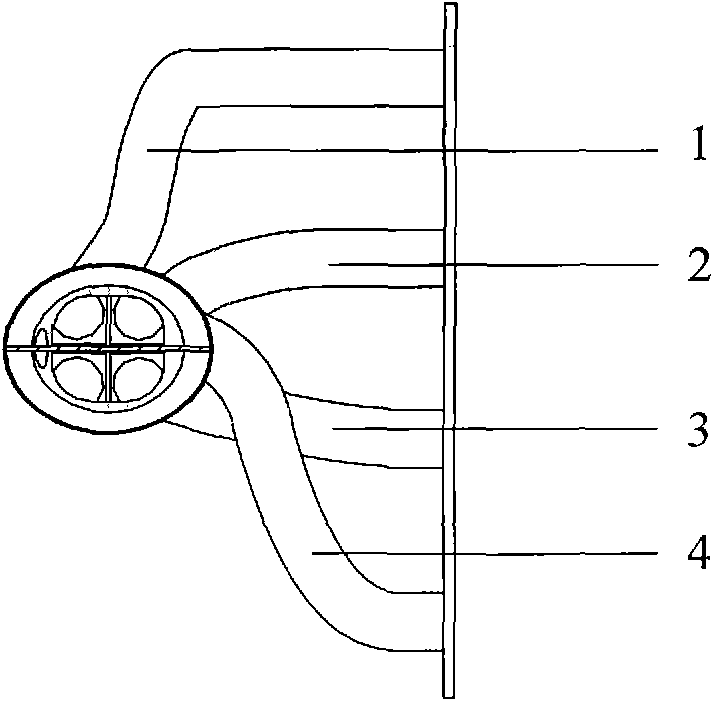

[0024] Such as Figure 1-Figure 3 As shown, in the embodiment of the present invention, the exhaust system of a four-cylinder engine is taken as an example for description. Such as figure 1 As shown in , from the left are the first exhaust branch pipe 1, the second exhaust branch pipe 2, the third exhaust branch pipe 3 and the fourth exhaust branch pipe 4, corresponding to the first cylinder, the second cylinder, and the third exhaust branch pipe of the engine respectively. cylinder and fourth cylinder. The engine ignition is sequentially ignited in the order of the first cylinder, the third cylinder, the fourth cylinder, the second cylinder and the first cylinder.

[0025] The exhaust manifold in the exhaust system mainly includes: a first exhaust branch pipe, a second exhaust branch pipe, a third exhaust branch pipe and a fourth exhaust branch pipe respectively connected with each cylinder, and a spindle-shaped pre-exhaust pipe. The catalytic converter, the exhaust front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com