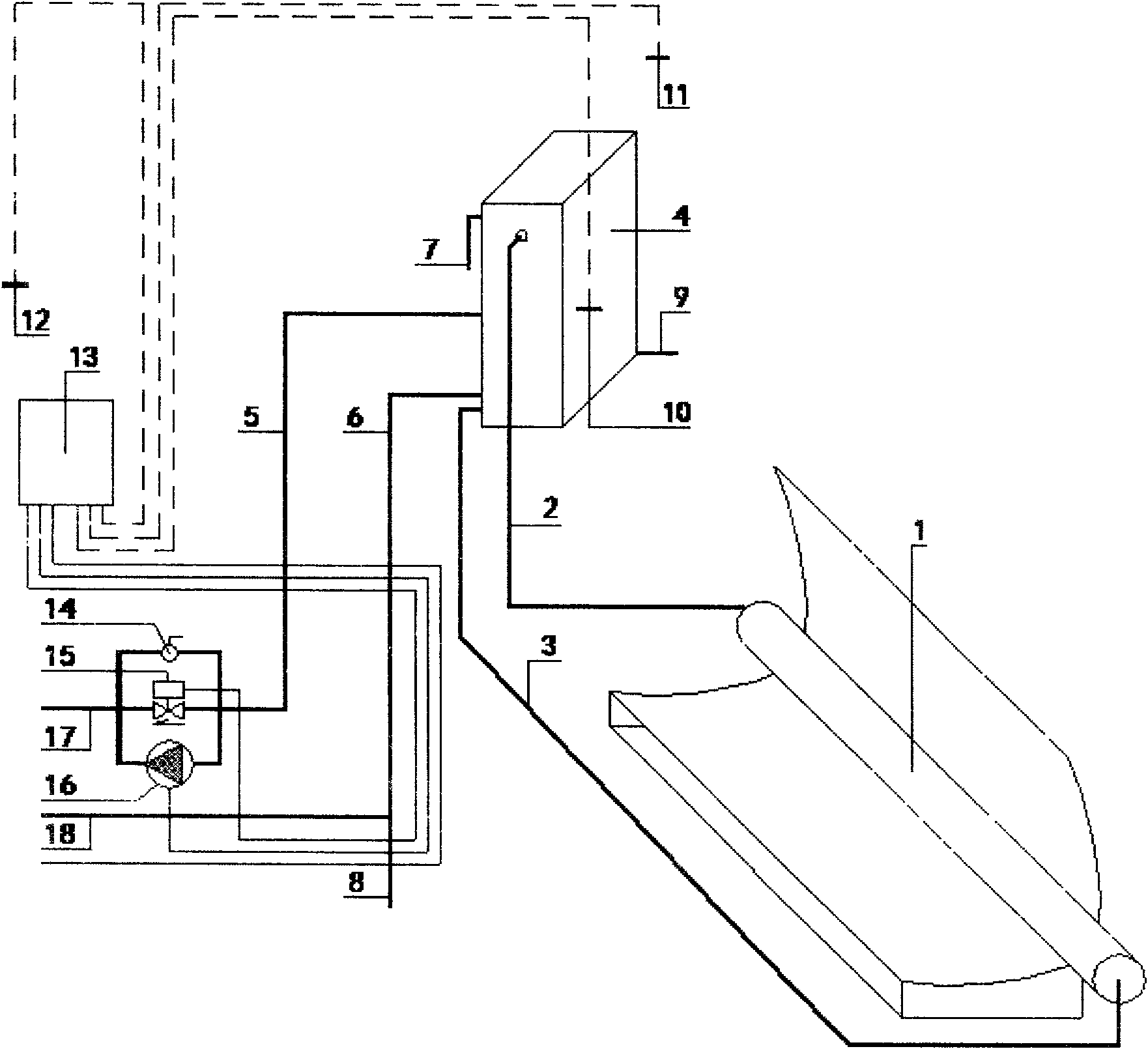

CPC (Composite Parabolic Condenser) parabola concentration solar energy heating system

A heating system and solar energy technology, applied in the field of solar energy utilization, can solve the problems of easy damage to the collector, short service life, high manufacturing and installation costs of the solar heat collection system, and achieve the effect of improving the heat collection efficiency and the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1. Determining the collector structure Through the process of project development, determine the structure of the optimal geometric size of the heat collector and concentrator of the CPC parabolic concentrating solar collector.

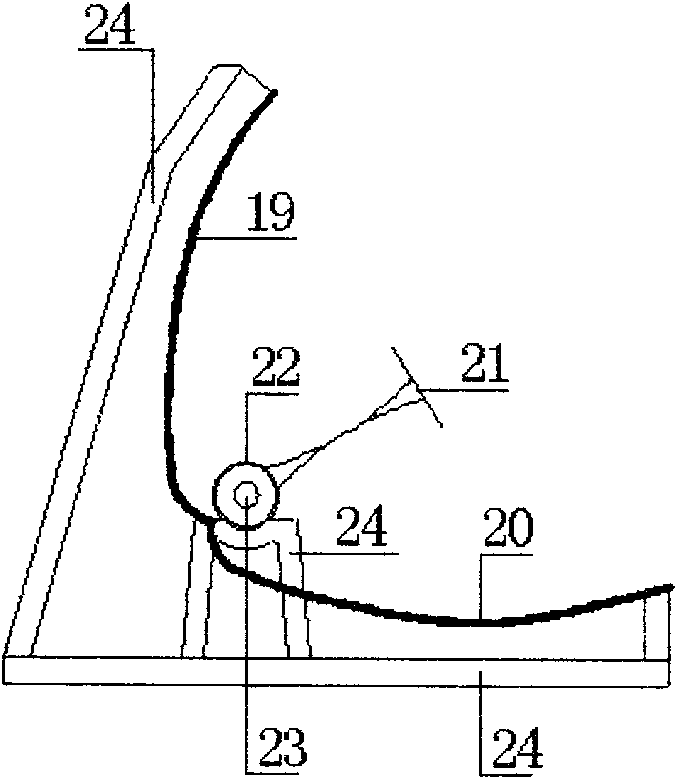

[0058] 2. Determine the heat collector The heat collector of the CPC concentrating solar heat collector is planned to adopt a composite structure of a circular tube heat aid plate. The circular tube is the main heat collector of the far-infrared coating, and the heat aid plate is a triangular wing-shaped secondary heat collector. The calculation and verification are based on the coordinate formula x=γsinα-ιcosα and y=-γcosα-ιsinα. The circular tube heat collector is used as the The double-sided involute in the center corresponds to the tangent of the circular tube to locate the maximum half acceptance angle of the sun of the collector.

[0059] 3. Make sure that the concentrator takes the moving point M(x1, z1) along the involute of the heat co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com