Vaporization heat fully recyclable lithium bromide central air-conditioning

A central air-conditioning and lithium bromide technology, which is applied in heating methods, air-conditioning systems, ventilation and heating energy recovery systems, etc., can solve the problems of lithium-bromide air-conditioning energy efficiency ratio less than 2, heat waste, and increased cooling water consumption of lithium-bromide air-conditioning , to achieve low power, make up for heat dissipation loss and heat transfer loss, and achieve the effect of low compressor power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

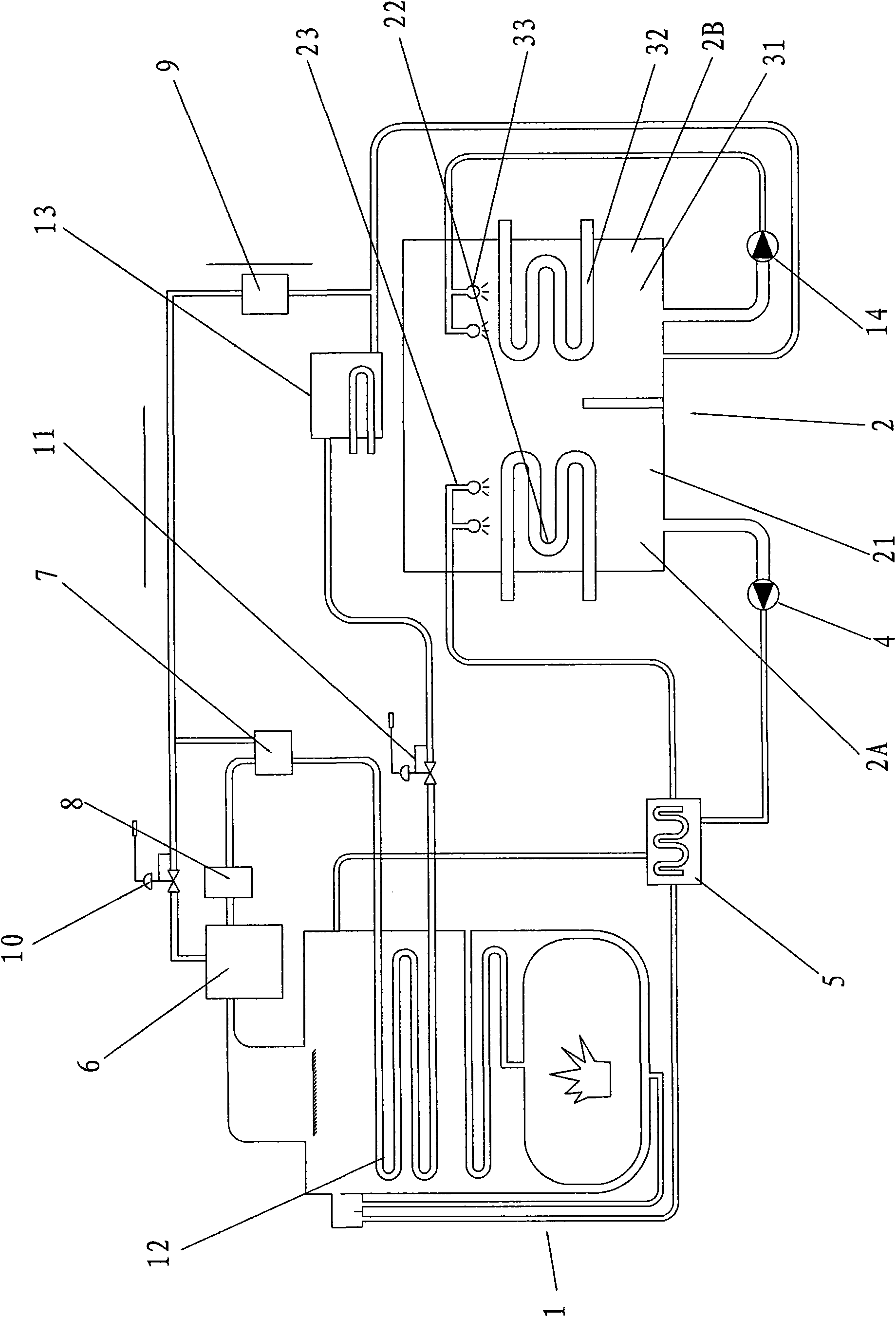

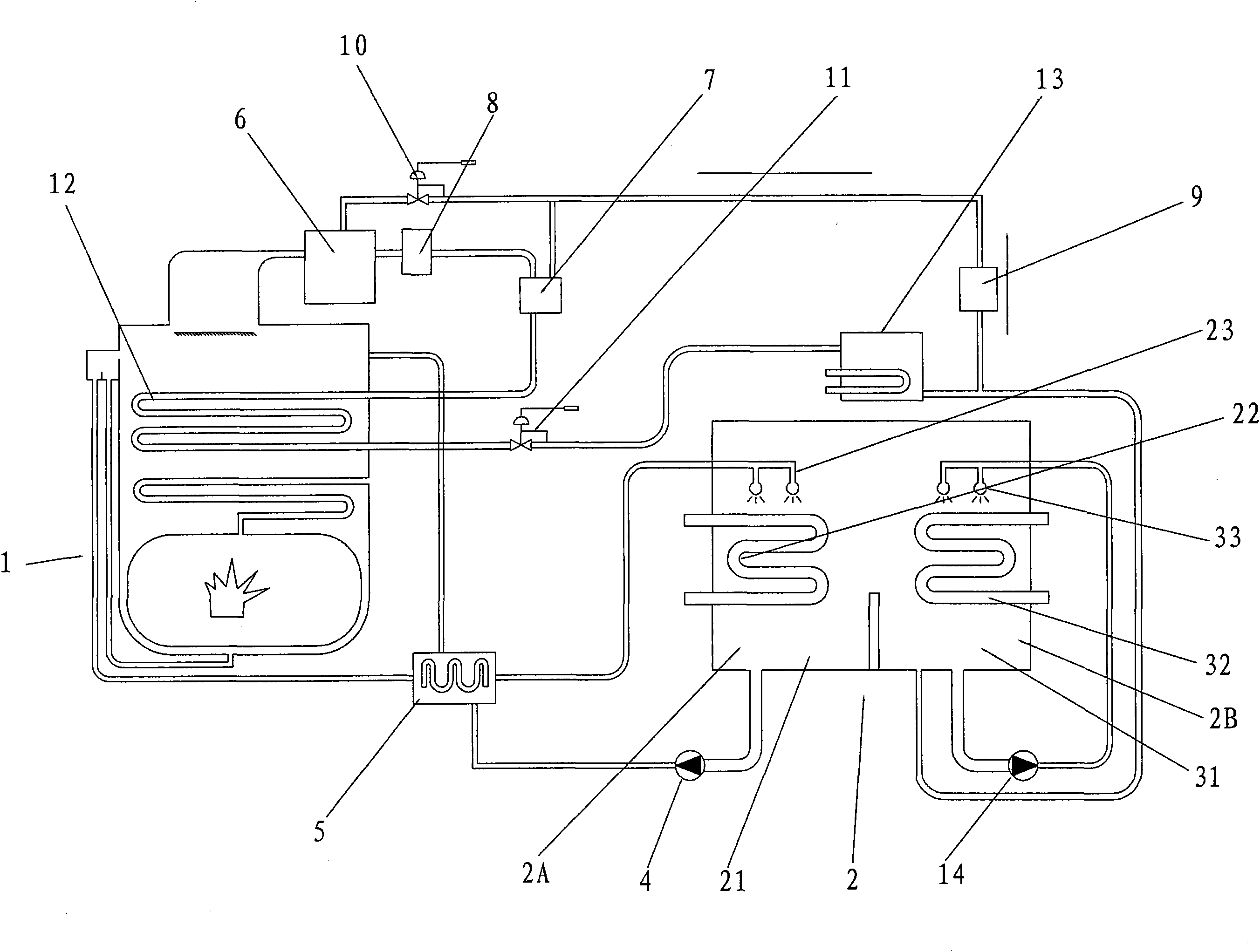

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] Such as figure 1 As shown, a lithium bromide central air conditioner with complete recovery of vaporization heat includes a high-pressure generator 1, a high-temperature heat exchanger 5, and an absorption evaporation chamber 2, and the absorption evaporation chamber 2 includes an absorption chamber 2A, an evaporation chamber 2B, and an absorption heat exchanger 22. Evaporation heat exchanger 32, refrigerant water nozzle 33 and low-temperature concentrated solution nozzle 23, the absorption chamber 2A is connected to the evaporation chamber 2B, the bottom of the absorption chamber 2A is the dilute solution plate 21, and the bottom of the evaporation chamber 2B is the refrigerant water plate 31, The refrigerant water nozzle 33 communicates with the refrigerant water pan 31 through the refrigerant pump 14; the dilute solution pan 21 communicates with the high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com