Phase change random access memory and manufacturing method thereof

A technology of a phase change memory and a manufacturing method, which is applied in the manufacturing of semiconductor/solid state devices, electric solid state devices, semiconductor devices, etc., can solve the problems of reducing the contact area between the bottom electrode 301 and the phase change layer 302, etc., achieve excellent heating effect, improve The effect of read and write speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

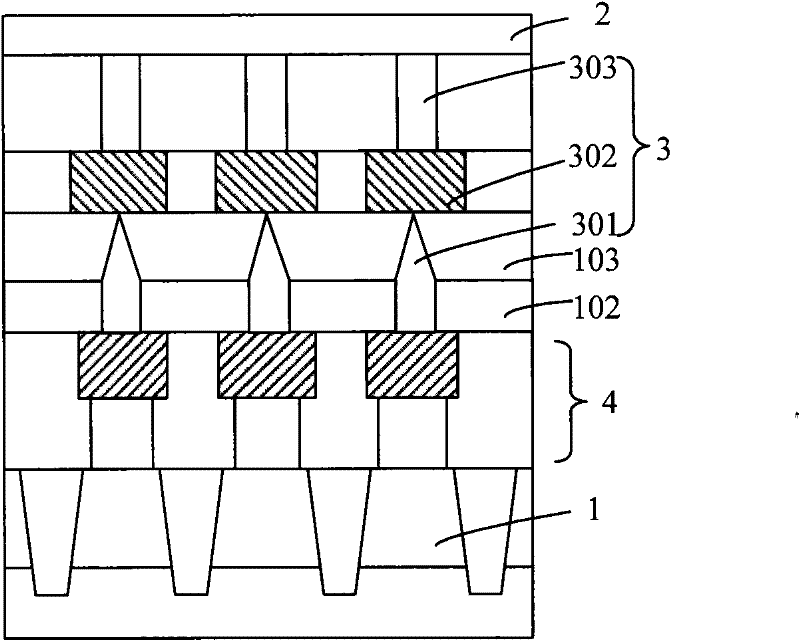

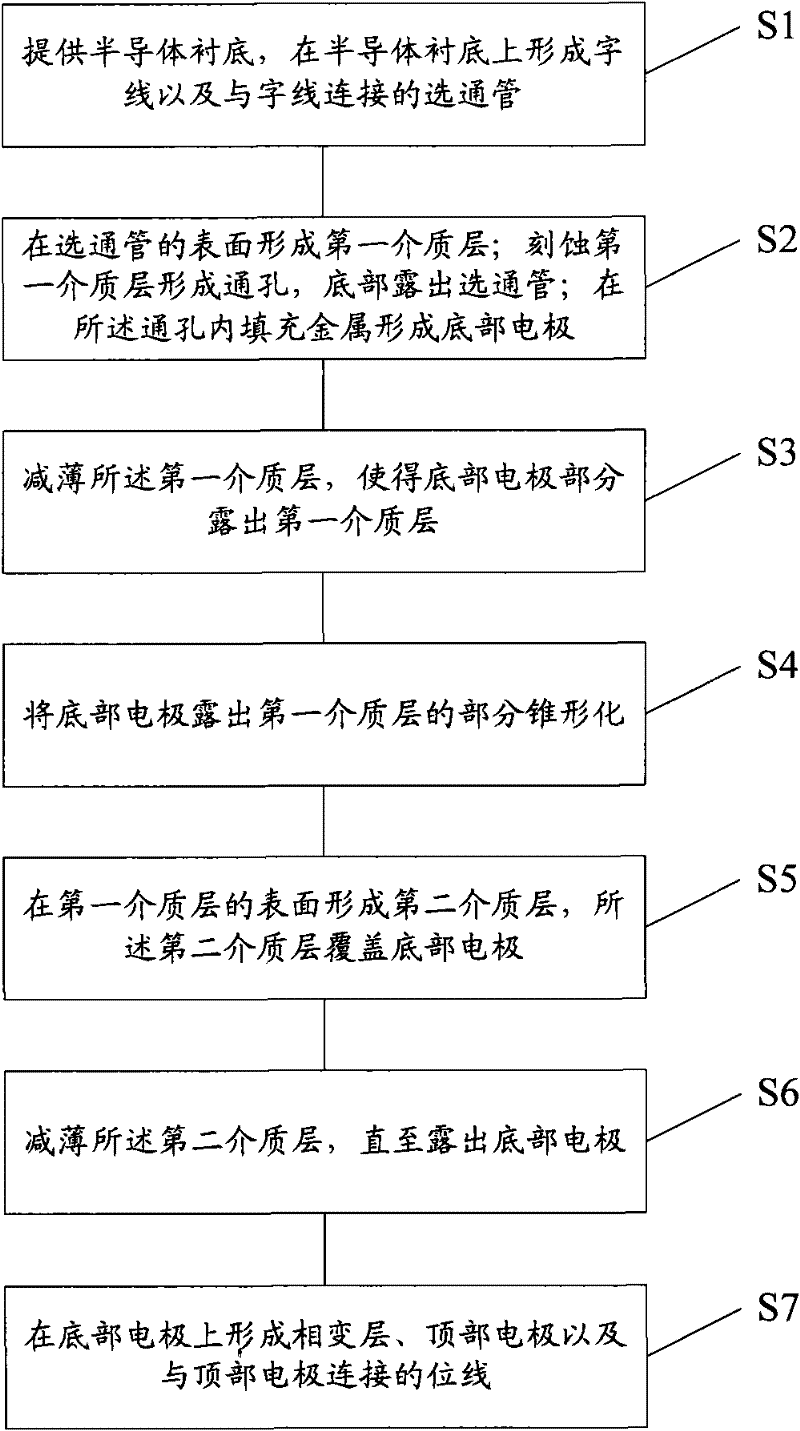

[0039] In the phase change memory formed by the existing manufacturing method, the bottom electrode is in the shape of an inverted trumpet, and the cross section of the top is larger than that of the bottom. Therefore, limited by the existing technology, it is difficult to further reduce the contact area with the phase change layer. The present invention By tapering the top end of the bottom electrode, the cone top forms an ohmic contact with the phase change layer, thereby achieving the purpose of reducing the contact area.

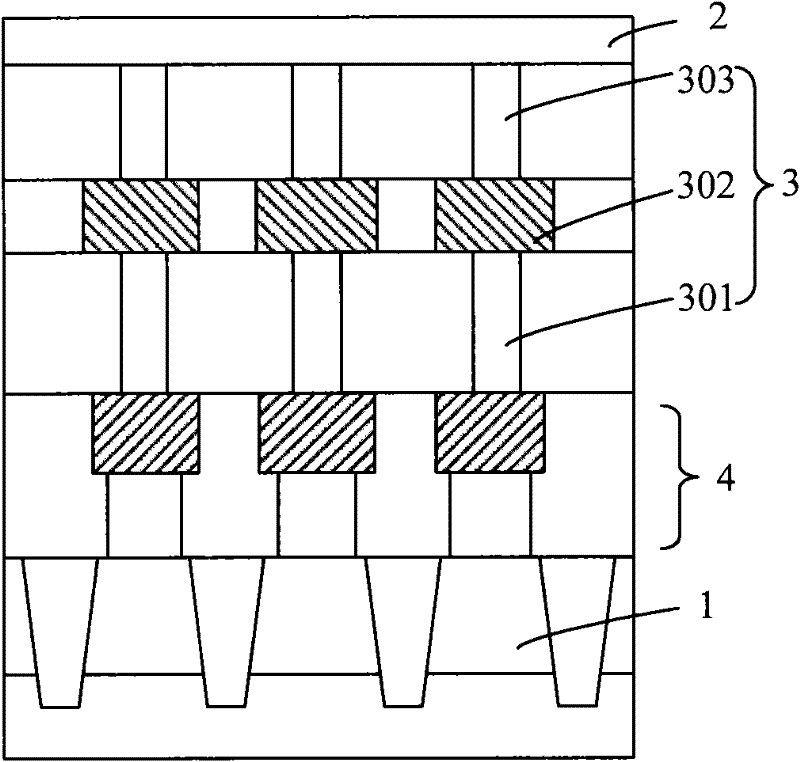

[0040] Such as figure 2 As shown, the phase change memory of the present invention includes:

[0041] Word line 1, bit line 2, phase change memory unit 3, and gate transistor 4;

[0042] The phase-change memory cell 3 includes a bottom electrode 301, a top electrode 303, and a phase-change layer 302 between the bottom electrode 301 and the top electrode 303; one end of the gate transistor 4 is electrically connected to the word line 1, and the other en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com