Drive control device of high-speed switch of silicon controlled switched capacitor

A technology of switching capacitors and high-speed switches, which is applied in the directions of reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problem that the implementation idea and the zero-crossing point of the optocoupler detection voltage have no obvious improvement, and the thyristor cannot be accurately detected. Problems such as zero-crossing, inability to work, fast switching conditions, etc., to avoid voltage fluctuations, reduce costs, and improve driving capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

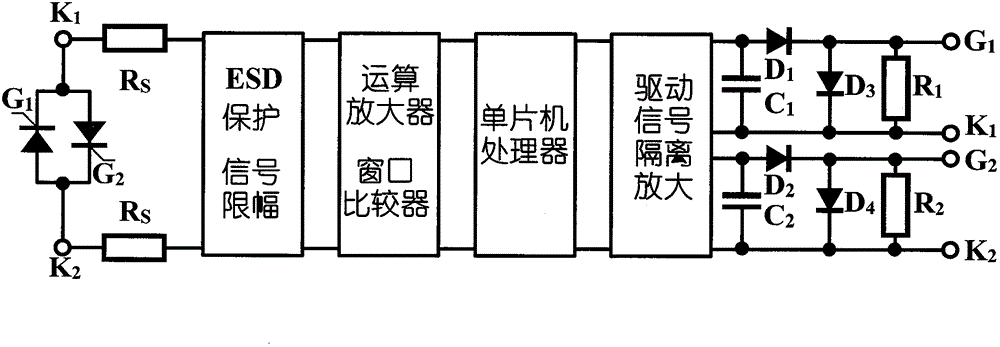

[0017] Such as figure 1 As shown, the drive control device of the thyristor switching capacitor high-speed switch of the present invention consists of a thyristor, an ESD protection and signal limiting module, an operational amplifier and a window comparator module, a single-chip processor, a driving signal isolation amplification module and The driving signal shaping circuit is composed of; the driving control device of the thyristor switching capacitor high-speed switch is connected in parallel with the two ends of the thyristor in the capacitive reactive power compensation device circuit, and two sampling resistors are connected in the control and protection circuit of the thyristor R s , two sampling resistors R s One end of the thyristor and the node K at both ends of the thyristor 1 and K 2 connection, the two sampling resistors R s The other end of the other end is connected with ESD protection and signal limiting module input respectively; The output terminal of ES...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com