Charging management method and charger for lithium ion battery pack

A lithium-ion battery pack and charging management technology, which is applied in battery circuit devices, current collectors, electric vehicles, etc., can solve the problems of poor charging capacity, reduced battery safety, poor battery consistency, etc., to improve low-temperature charging capacity, cycle Effects of life improvement and reduction of battery polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

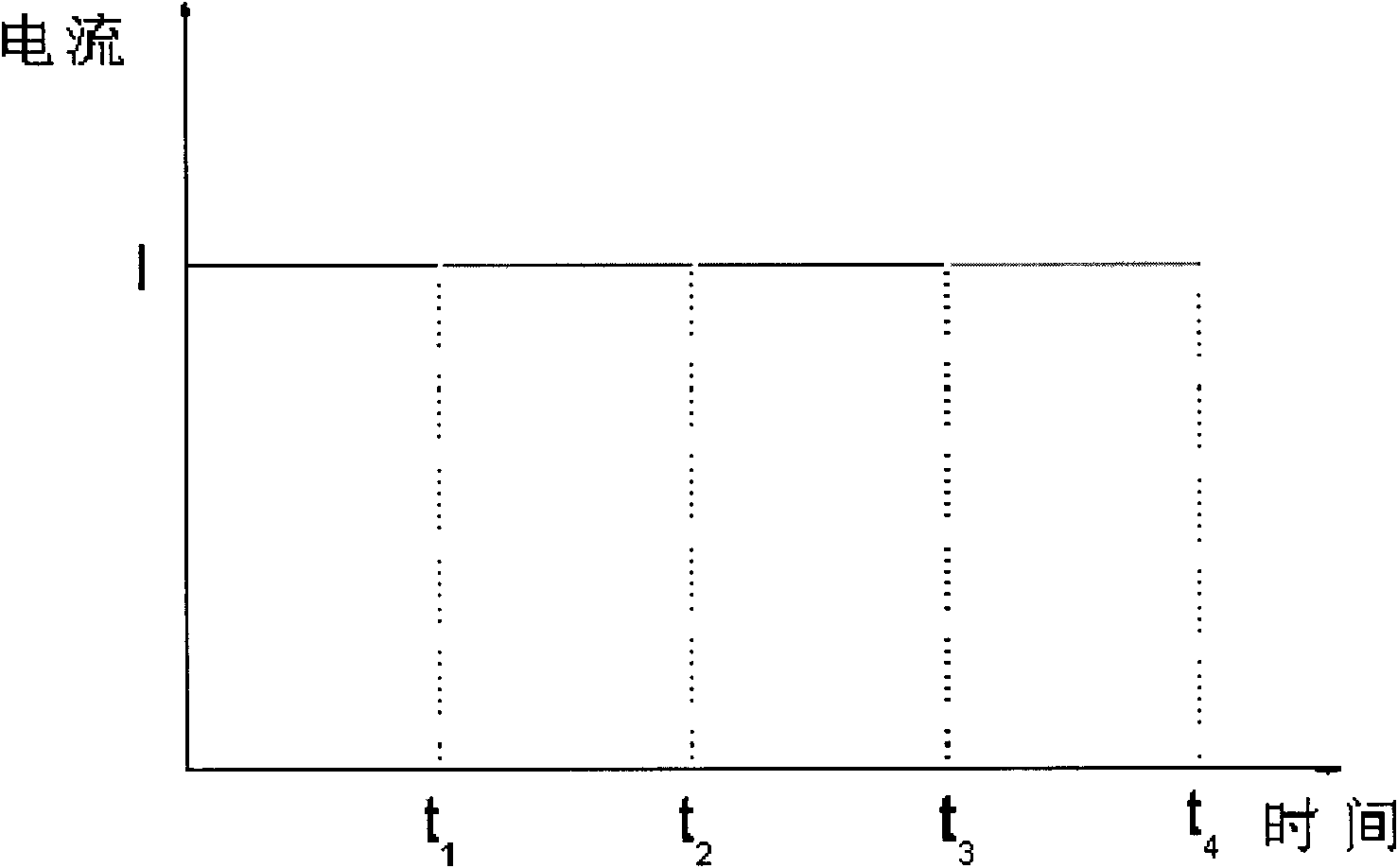

[0026] First Embodiment Square Wave Charging

Embodiment 1

[0027] Embodiment 1, charging under low temperature conditions

[0028] Using the square wave charging method, the battery pack is a lithium iron phosphate battery pack, and the charging ambient temperature is -20°C. It is divided into two independent groups (A group and B group). Each group has a battery voltage of 200V and a capacity of 75Ah. The groups are charged alternately, that is, group A charges for 5 minutes and rests for 5 minutes (at the same time, group B stands for 5 minutes and charges for 5 minutes), and the charging current is 35A. If it cooperates with the whole process of equalization charging at the same time, it is required that the difference between the highest and the lowest voltage of the single cells in the battery pack exceeds 50mV to start equalization, and when the difference between the highest and the lowest voltage of the single cells in the battery pack is lower than 10mV, stop equalization and continue square wave charging. The cycle life of t...

Embodiment 2

[0032] Embodiment 2, adopt the square wave charging method, the battery pack is a lithium manganese oxide battery pack, the charging environment temperature is 26 ℃, the battery pack is divided into two independent groups (A group and B group), each group battery voltage 200V, capacity 75Ah, The two groups A and B are charged alternately, that is, group A charges for 10 minutes and rests for 10 minutes (at the same time, group B stands for 10 minutes and charges for 10 minutes), and the charging current is 35A. If it cooperates with the whole process of equalization charging at the same time, it is required that the difference between the highest and the lowest voltage of the single cells in the battery pack exceeds 35mV to start equalization, and when the difference between the highest and the lowest voltage of the single cells in the battery pack is lower than 20mV, stop equalization and continue square wave charging. The cycle life of the battery pack is 1550 times (the capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com