Light lattice sandwich plate and method for manufacturing same by mechanical drilling

A mechanical drilling and sandwich panel technology, which is applied in drilling/drilling equipment, boring/drilling, manufacturing tools, etc., can solve the problems of unsuitable mass production, poor structural performance of sandwich panels, etc., and achieve weight reduction , improve structural performance, and achieve simple effects in technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

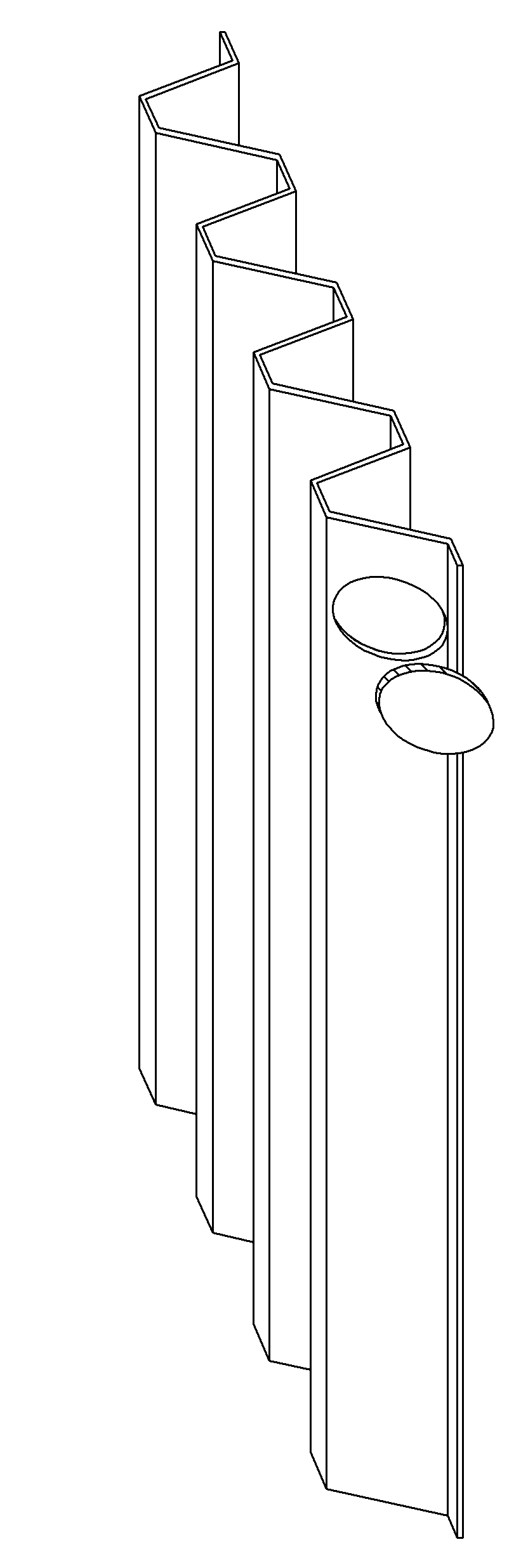

[0040] Specific implementation mode one: the following combination Figure 7 Describe this embodiment, a kind of lightweight lattice sandwich panel of this embodiment, it comprises the corrugated plate 1 with hole, upper panel 2 and lower panel 3, the upper top surface of corrugated plate 1 with hole and upper panel 2 Fixed together, the lower bottom surface of the corrugated plate 1 with holes and the lower panel 3 are fixed together, and a row of through holes is distributed on each inclined side of the corrugated plate 1 with holes. The through holes may be uniformly or unevenly distributed on the inclined side, which is determined according to actual needs.

specific Embodiment approach 2

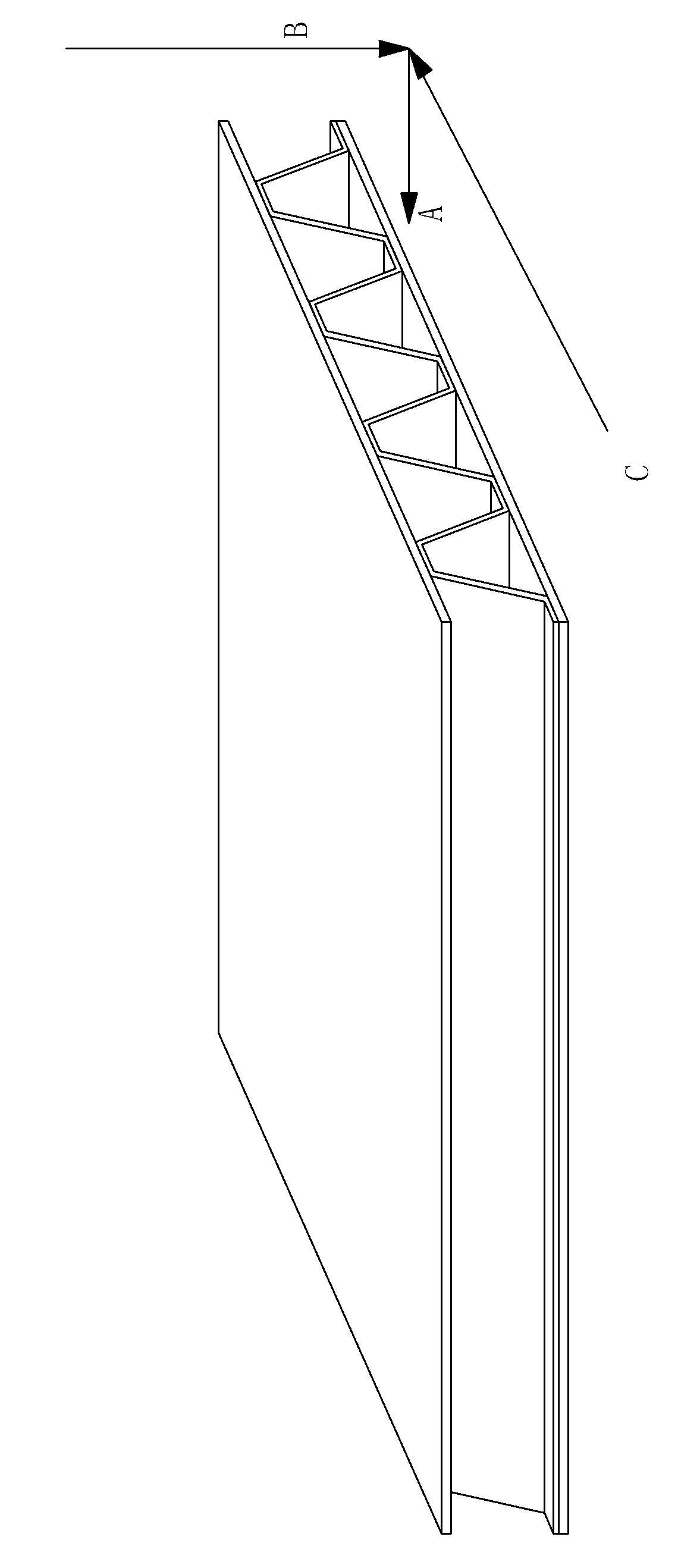

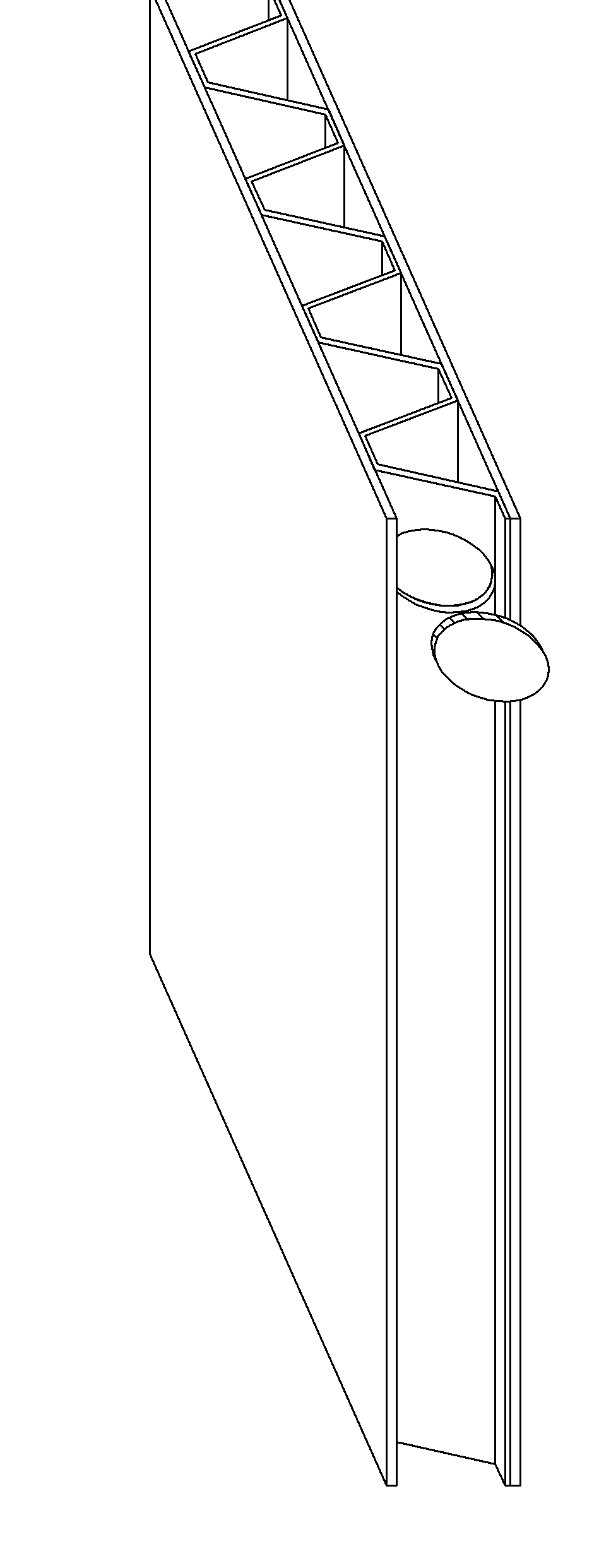

[0041] Specific implementation mode two: the following combination Figure 1 to Figure 4 , Figure 7 to Figure 11 To illustrate this embodiment, this embodiment adopts the method of mechanical drilling to prepare the lightweight lattice sandwich panel described in Embodiment 1, which includes the following steps:

[0042] Step 1. Fix the corrugated board with the upper and lower panels to form a workpiece to be processed, and mark the drilling position on the inclined side of the corrugated board;

[0043] Step 2. Place the workpiece to be processed horizontally on the drilling machine table, and fix and clamp it with a clamp, adjust the drilling machine equipment, and use a slender diamond tool to drill holes at all drilling positions. The tool feeding direction is the same as the upper The panels are parallel and perpendicular to the corrugated board lines,

[0044] Process parameters of mechanical drilling:

[0045] The tool feed speed is 0.1mm / s~2mm / s, and the tool spee...

specific Embodiment approach 3

[0057] Specific implementation mode three: the following combination Figure 1 to Figure 9 To illustrate this embodiment, this embodiment adopts the method of mechanical drilling to prepare the lightweight lattice sandwich panel described in Embodiment 1, which includes the following steps:

[0058] Step 1. Pretreat the corrugated plate to be processed: mark the drilling position on the inclined side of the corrugated plate;

[0059]Step 2. Place the corrugated plate horizontally on the drilling machine table, and fix and clamp it with a fixture, adjust the drilling machine equipment, and use a slender diamond tool to drill at the drilling position. The tool feeding direction is parallel to the upper panel and is in line with the The corrugated board's corrugated lines are vertical,

[0060] Process parameters of mechanical drilling:

[0061] The tool feed speed is 0.1mm / s~2mm / s, and the tool speed is 100 rpm~3000 rpm;

[0062] Step 3. After drilling the corrugated plate ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com