High-adsorbability porous silicon dioxide absorbing agent and preparation method and application thereof

A porous silica, high adsorption technology, applied in the direction of silica, silica, chemical instruments and methods, etc., can solve the problems of low dehumidification capacity, small dehumidification capacity, high regeneration temperature, etc., and achieve high adsorption/desorption rate , Large adsorption capacity, high adsorption capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) 3g polyvinylpyrrolidone (PVP) was dissolved in 87g water, and 15g concentrated hydrochloric acid (37% by mass) was added to adjust the acidity of the solution to obtain a water / acid / PVP solution;

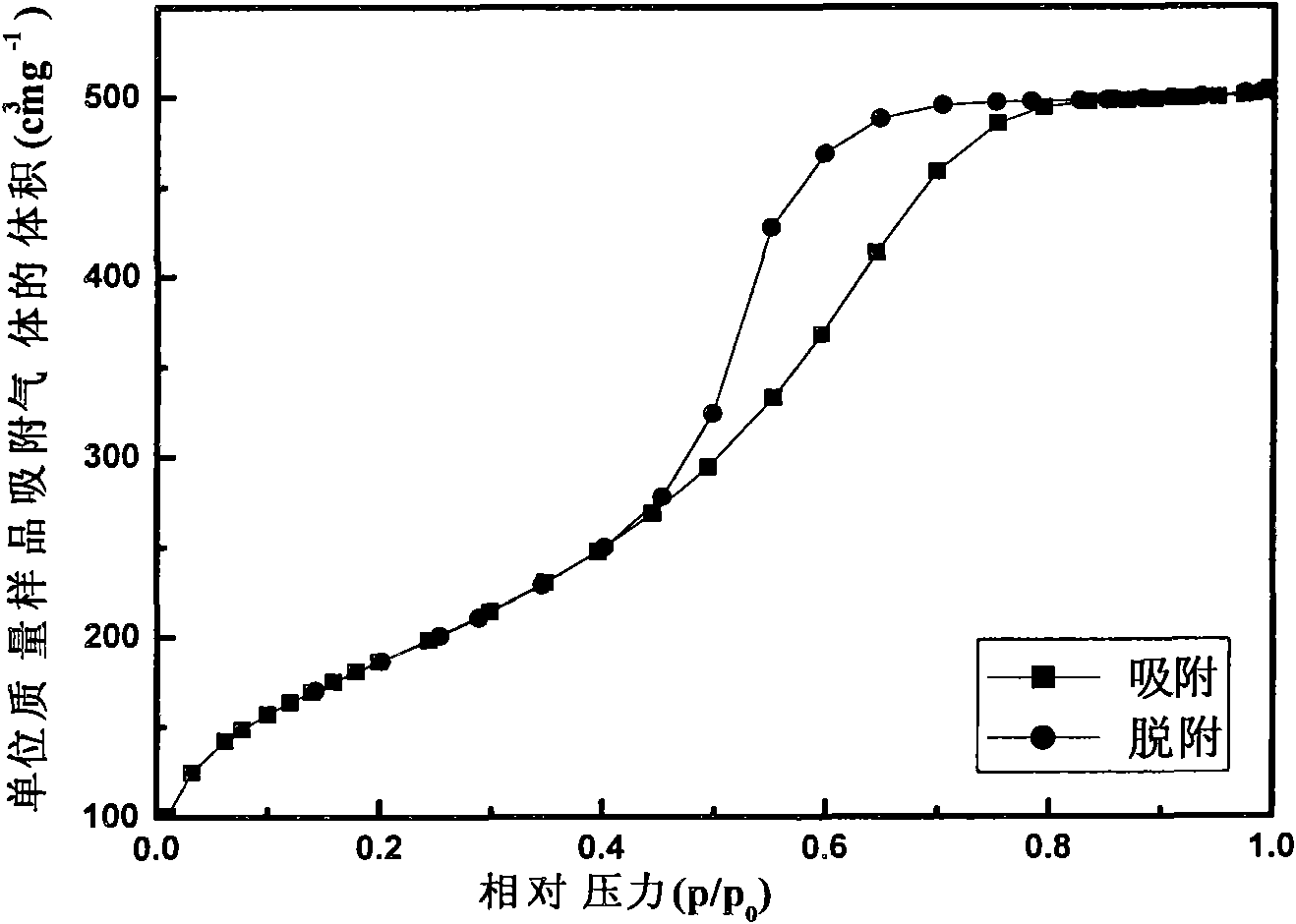

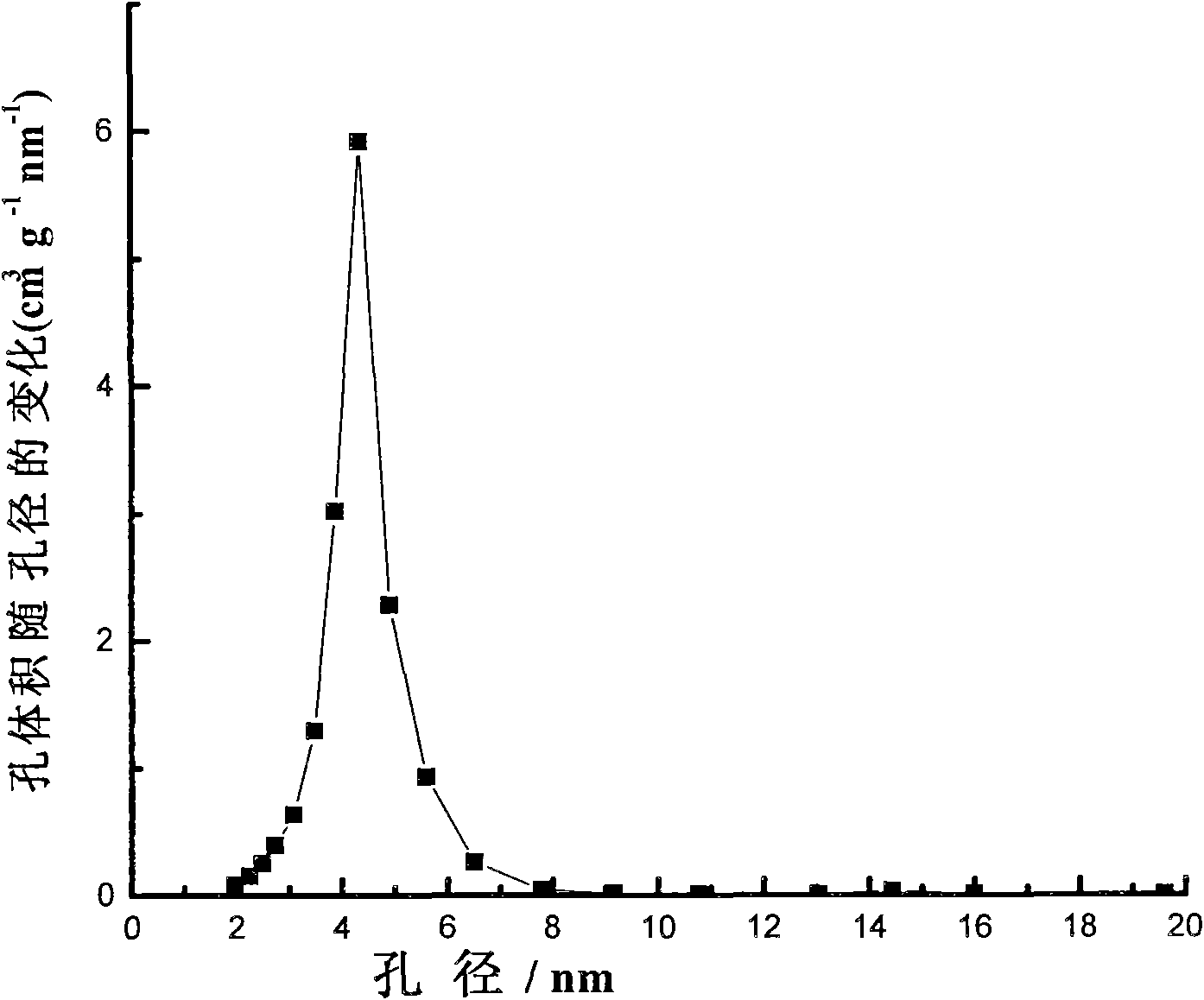

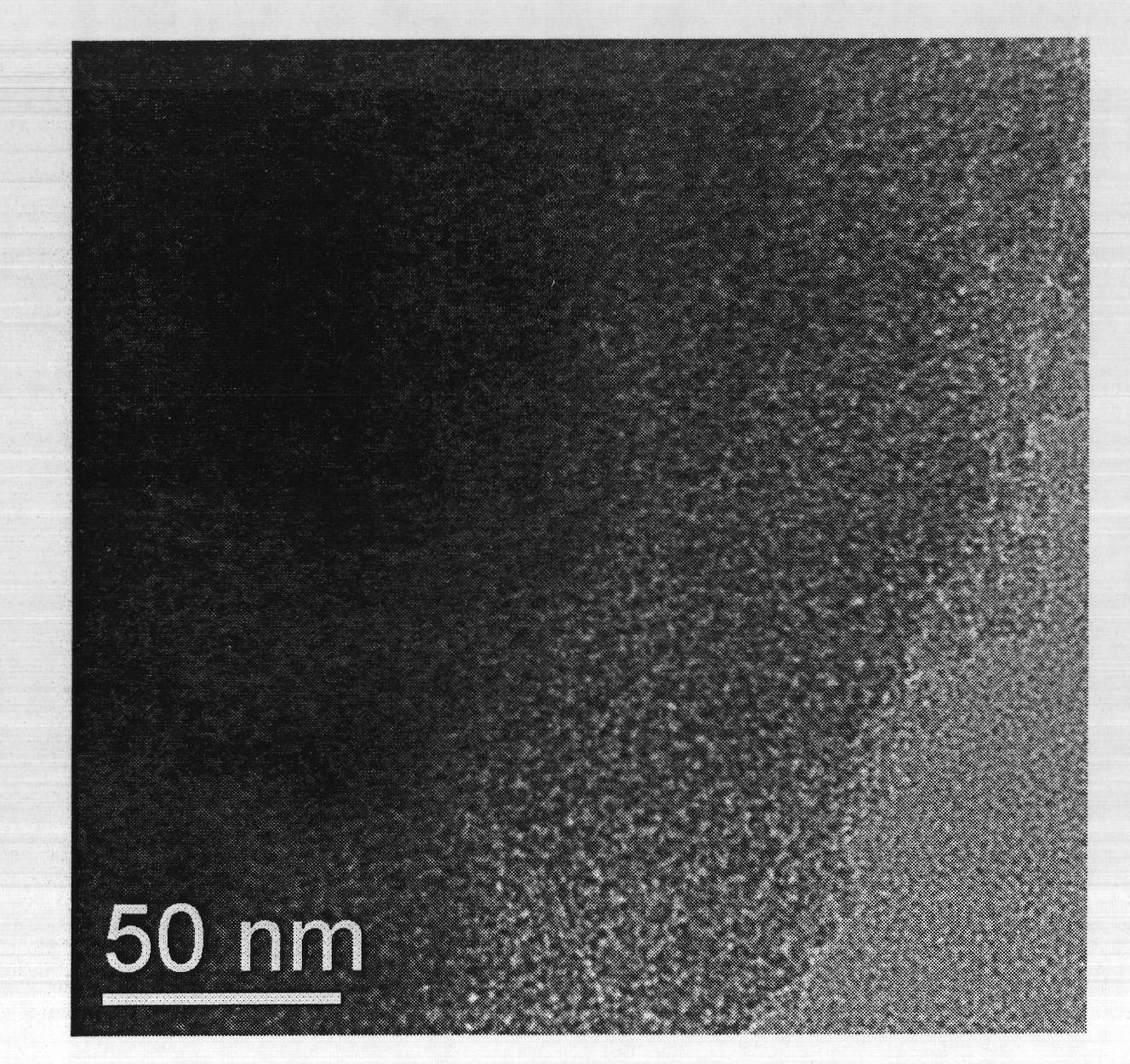

[0034] (2) Add 3g tetraethyl orthosilicate (TEOS) dropwise to the water / acid / PVP solution, stir at 35°C for 24 hours to obtain a sol, gelatinize at 80°C for 48 hours, dry at 95°C for 24 hours, and bake The dried sample was calcined at a temperature of 500° C. for 3 hours with a heating rate of 0.5° C. / min to obtain a highly adsorbable porous silica adsorbent. N 2 - Determination of its specific surface area and pore size distribution by adsorption and desorption, the determination uses a common N 2 -Adsorption-desorption instrument, the adsorbent was vacuum treated at 200°C for 10 hours before measurement; 2 -BET specific surface area and BJH pore size distribution are calculated by the built-in software of the adsorption-desorption instrument. The porous structure was...

Embodiment 2

[0037] (1) 1g of polyvinylpyrrolidone (PVP) was dissolved in 84g of water, and 10g of concentrated hydrochloric acid (37% by mass) was added to adjust the acidity of the solution to obtain a water / acid / PVP solution;

[0038] (2) Add 6g of orthomethyl silicate (TMOS) dropwise to the water / acid / PVP solution, stir at 35°C for 24 hours to obtain a sol, gel at 75°C for 56 hours, dry at 85°C, and dry The sample was calcined at 550°C for 3 hours with a heating rate of 0.5°C / min to obtain a highly adsorbable porous silica adsorbent. Specific surface area, pore size distribution, pore structure observation, adsorption capacity and adsorption / desorption rate determination methods are the same as in Example 1.

[0039] (3) The above-mentioned sol is impregnated on the ceramic rotor, gelled at 75°C for 56 hours, dried at 85°C, programmed to heat up to 550°C for 3 hours, and the heating rate is 0.5°C / min to make solid porous carbon dioxide. Silicon dehumidification wheel core.

Embodiment 3

[0041] (1) 4g polyvinylpyrrolidone (PVP) was dissolved in 76g water, and 20g concentrated hydrochloric acid (37% by mass) was added to adjust the acidity of the solution to obtain a water / acid / PVP solution;

[0042] (2) Add 8g tetraethyl orthosilicate (TEOS) dropwise to the water / acid / PVP solution, stir at 35°C for 20 hours to obtain a sol, gelatinize at 80°C for 48 hours, dry at 100°C, and dry The sample was calcined at 500°C for 4 hours with a heating rate of 0.5°C / min to obtain a highly adsorbable porous silica adsorbent. Specific surface area, pore size distribution, pore structure observation, adsorption capacity and adsorption / desorption rate determination methods are the same as in Example 1.

[0043] (3) The above-mentioned sol is impregnated on the ceramic rotor, gelled at 80°C for 48 hours, dried at 100°C, programmed to heat up to 500°C for 4 hours, and the heating rate is 0.5°C / min to make solid porous carbon dioxide. Silicon dehumidification wheel core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com