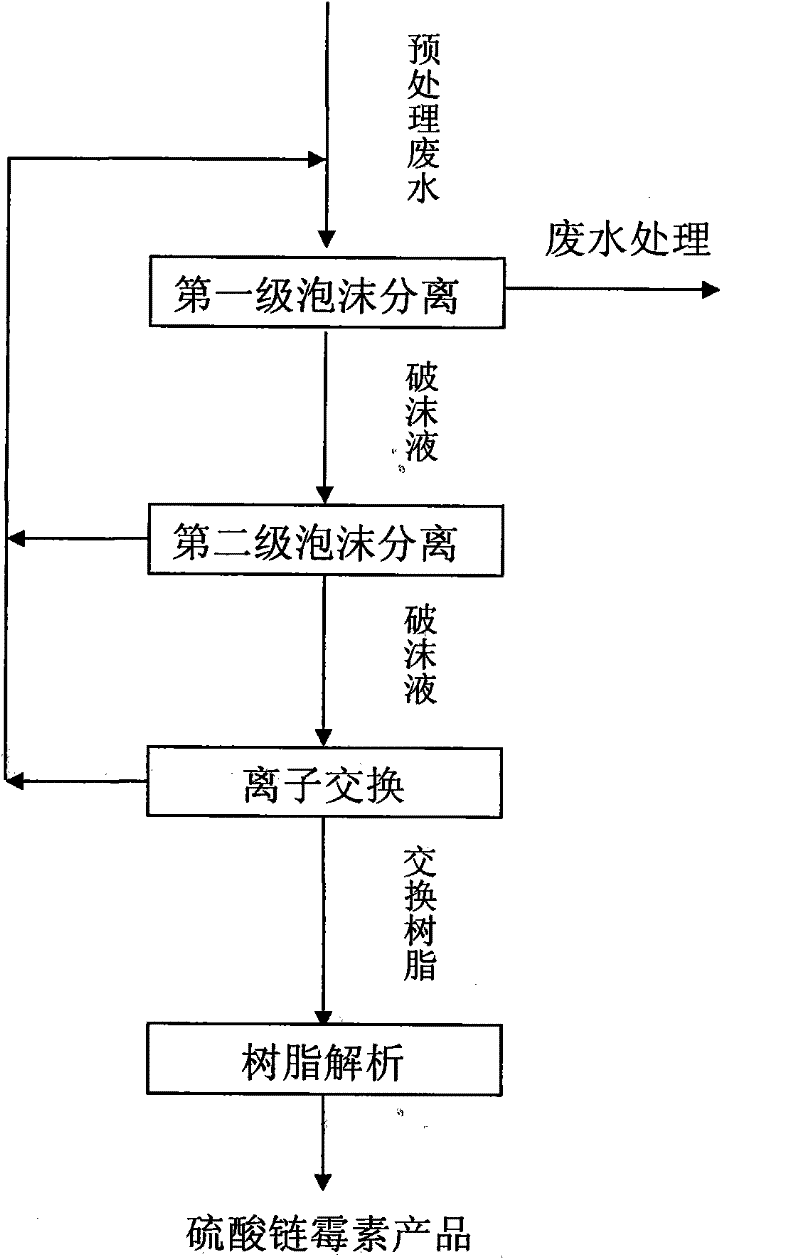

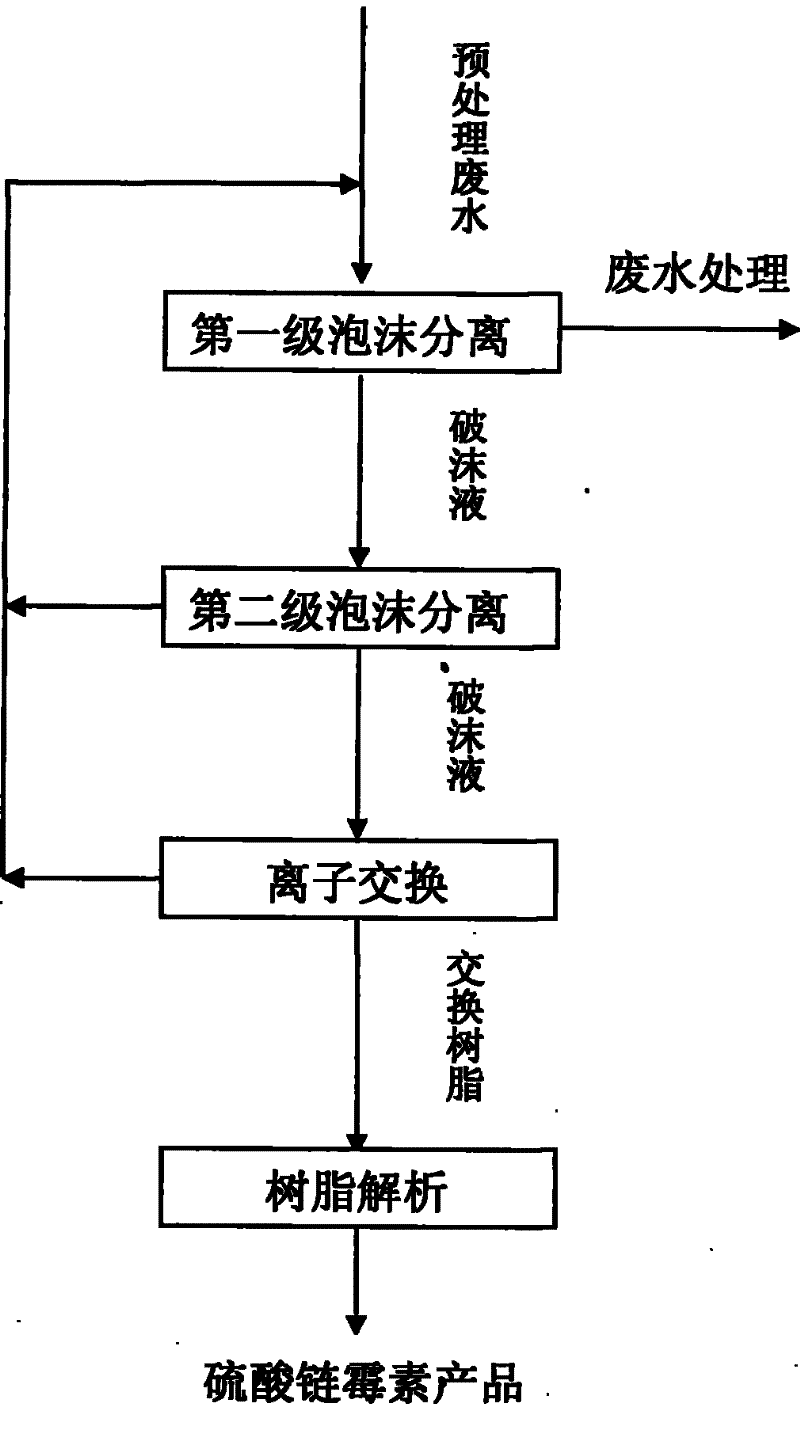

Process for recovering streptomycin sulphate from waste water by coupling foam separation and ion exchange

A streptomycin sulfate and foam separation technology, applied in ion exchange water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of high cost, difficult operation and unstable effect of membrane separation process and other problems, to achieve the effect of wide application range, simple and convenient operation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The first step, the collection and detection of streptomycin sulfate wastewater: collect streptomycin sulfate wastewater, the mass concentration of streptomycin sulfate is 0.52g / L after testing, and the pH is 4.2;

[0037]Second step, streptomycin sulfate wastewater pretreatment: the pH value of the streptomycin sulfate wastewater described in the first step is adjusted to 6.0 with 0.1mol / L sodium hydroxide solution;

[0038] The third step, secondary foam separation and extraction of streptomycin sulfate: the first stage of foam separation, adding anionic surfactant SDS to the streptomycin sulfate wastewater after the second step pretreatment, the added SDS is mixed with the wastewater The mass ratio of streptomycin sulfate contained is 1:1, the first separation is carried out with a bubble column, the temperature is 20°C, and the superficial gas flow rate is 3.310 -4 m / s, the filling capacity is 200mL, and the foam layer is broken by the foam breaking method, and the ...

Embodiment 2

[0042] The first step, the collection and detection of streptomycin sulfate wastewater: collect streptomycin sulfate wastewater, the mass concentration of streptomycin sulfate is 0.54g / L after testing, and the pH is 4.5;

[0043] Second step, streptomycin sulfate wastewater pretreatment: the pH value of the streptomycin sulfate wastewater described in the first step is adjusted to 6.5 with the sodium hydroxide solution of 0.2mol / L;

[0044] The third step, secondary foam separation and extraction of streptomycin sulfate: the first stage of foam separation, adding anionic surfactant SDS to the streptomycin sulfate wastewater after the second step pretreatment, the added SDS is mixed with the wastewater The mass ratio of streptomycin sulfate contained is 0.4:1, the first separation is carried out with a bubble column, the temperature is 23°C, and the superficial gas flow rate is 9.910 -4 m / s, the filling capacity is 300mL, and the foam layer is broken by the foam breaking method...

Embodiment 3

[0048] The first step, the collection and detection of streptomycin sulfate wastewater: collect streptomycin sulfate wastewater, the mass concentration of streptomycin sulfate is 0.50g / L after testing, and the pH is 5.0;

[0049] Second step, streptomycin sulfate wastewater pretreatment: the pH value of the streptomycin sulfate wastewater described in the first step is adjusted to 7.0 with the sodium hydroxide solution of 0.3mol / L;

[0050] The third step, secondary foam separation and extraction of streptomycin sulfate: the first stage of foam separation, adding anionic surfactant SDS to the streptomycin sulfate wastewater after the second step pretreatment, the added SDS is mixed with the wastewater The mass ratio of streptomycin sulfate contained is 0.6:1, the first separation is carried out with a bubble column, the temperature is 25°C, and the superficial gas flow rate is 6.610 -4 m / s, the filling capacity is 400mL, and the foam layer is broken by the foam breaking method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com