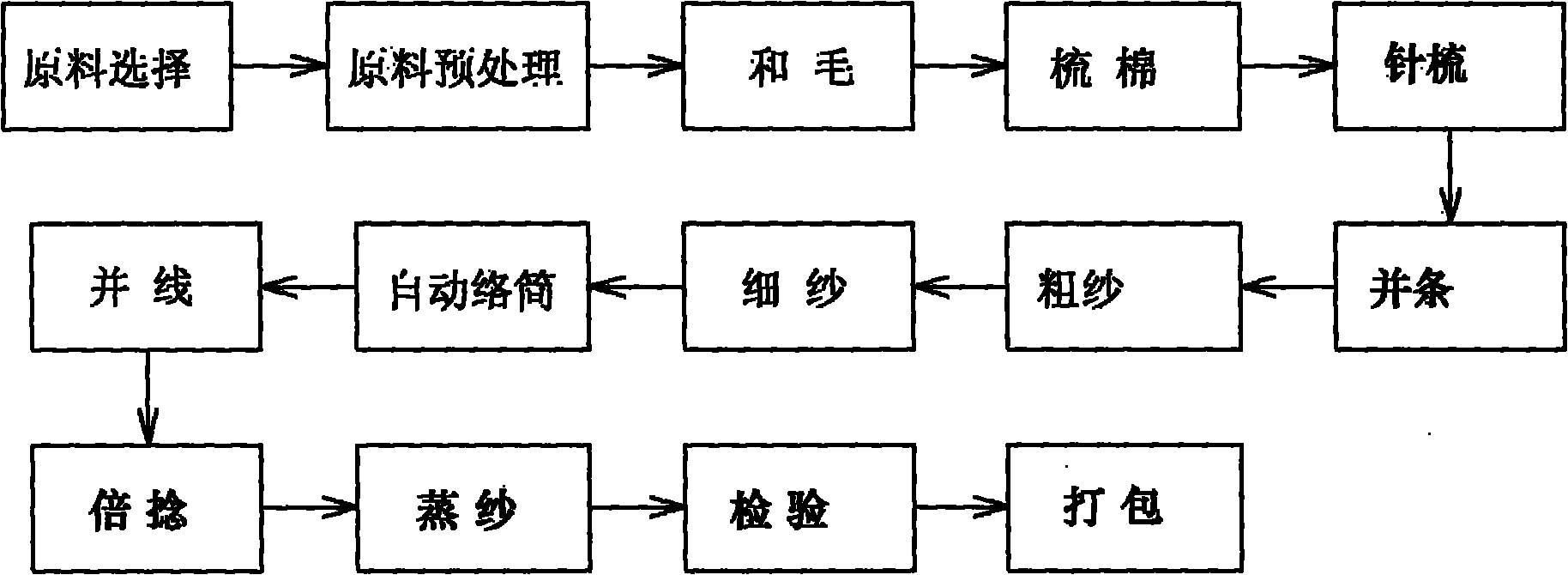

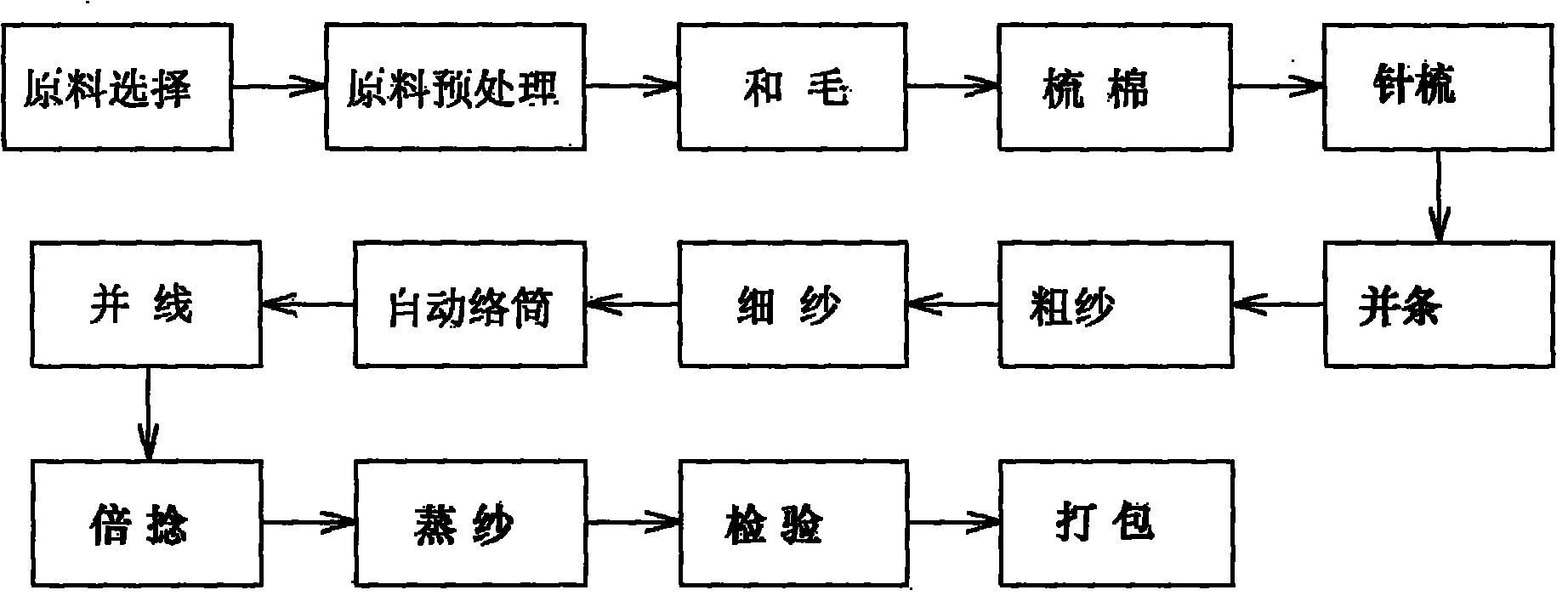

Production process of modal fiber, bamboo fiber and cashmere fiber knitting yarn

A technology of modal fiber and cashmere fiber, which is applied in the field of knitting yarn production to achieve good cost performance, comfortable wearing and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Examples, see figure 1 Shown, modal, bamboo fiber and cashmere fiber knitting yarn production process, 1), choose modal, bamboo fiber and cashmere fiber raw material,

[0033] Modal fiber specification is 1.25D×38mm,

[0034] Bamboo fiber specification is 1.25D×38mm,

[0035] Cashmere fiber specifications are average fineness 14.61μm, dispersion coefficient 22.04%, main body base 88.86%, average length: 35.33mm, and short cashmere rate below 20mm 7.13%;

[0036] 2), raw material pretreatment,

[0037] Adopt modal fiber and bamboo fiber to open once, add antistatic agent solution by 1% of raw material weight, antistatic agent solution proportioning is, antistatic agent: water=1: 5, obtain the modal fiber after pretreatment and pretreatment After the bamboo fiber;

[0038] Cashmere fiber is opened once, adds antistatic agent solution by 1% of raw material weight, adds and crude oil by 1.5% of raw material weight, and crude oil: antistatic agent: water=1: 1: 5, obtains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fineness | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com