System and method for testing lens parameters based on Hartmann-Shark sensor

A lens parameter and test system technology, applied in the direction of testing optical performance, instruments, measuring devices, etc., can solve the problems of single test lens parameters and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

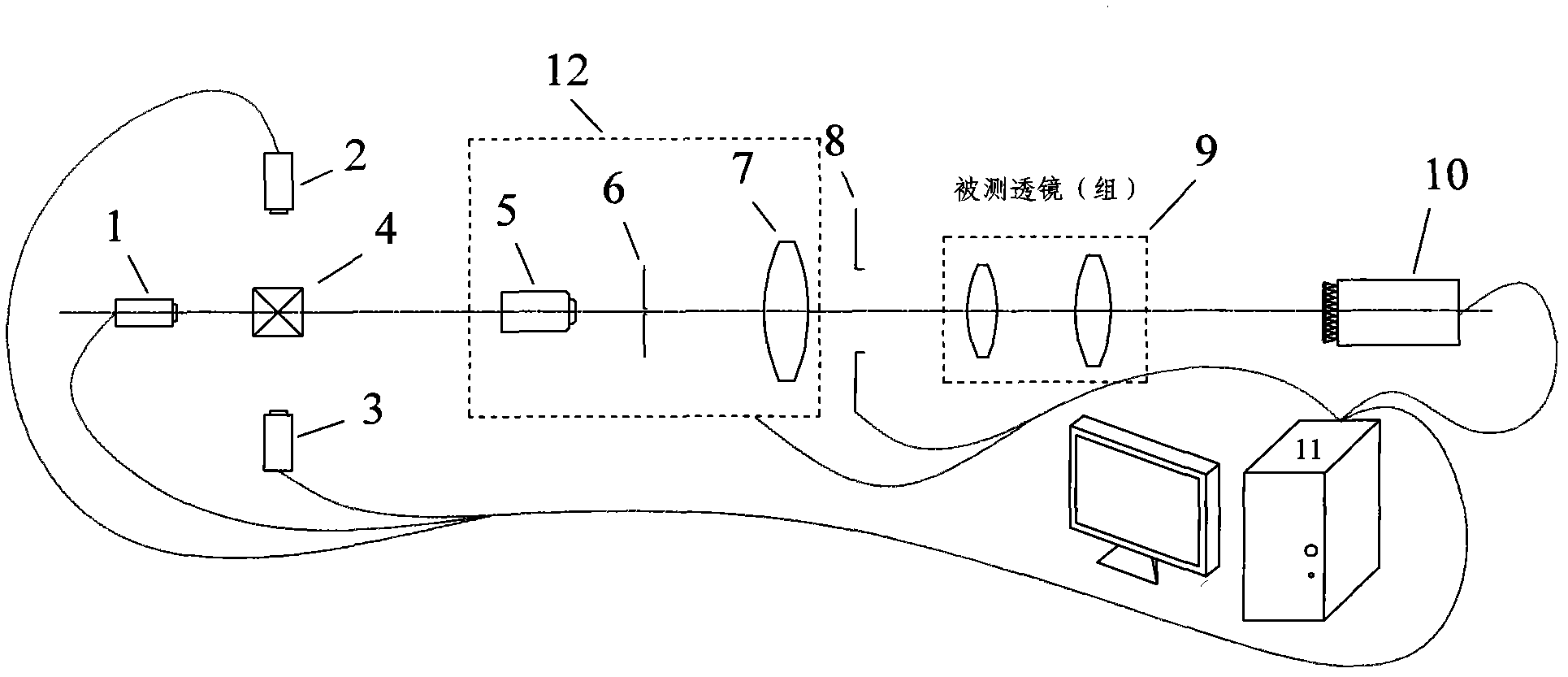

[0017] Such as figure 1 The schematic block diagram of the system structure is shown, and the lens parameter test system based on the Hartmann-Shack sensor includes three wavelength-tunable laser sources 1, 2, 3, a beam splitter 4, a beacon light collimation system 12, and an aperture control system. 8. The measured lens (group) 9, the Hartmann-Shack wavefront sensor 10 and the computer 11, the wavelength-tunable laser light sources 1, 2, and 3 respectively point vertically to the three incident surfaces of the beam splitter 4, and their adjustable wavelengths respectively cover Three different wavelength ranges, the three wavelength ranges can be properly selected according to the specific measurement content and requirements of the measured lens (group) 9. In this example, F light (486.13nm) and C light (656.27nm) are selected and D light (587.56nm) lasers with three wavelengths; the beacon light collimation system 12 is located in the common exit direction of the three-way ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com