Group control system for multi-path start-stop control

A technology of start-stop control and group control, applied in electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of high equipment failure rate and complicated operation process, and achieve the effect of saving time and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

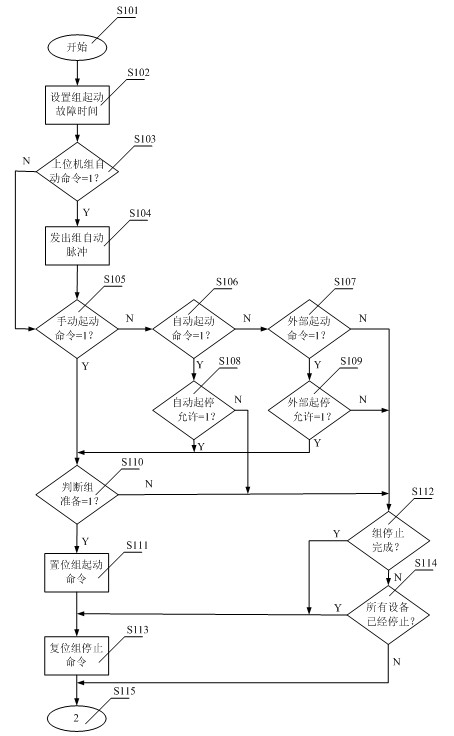

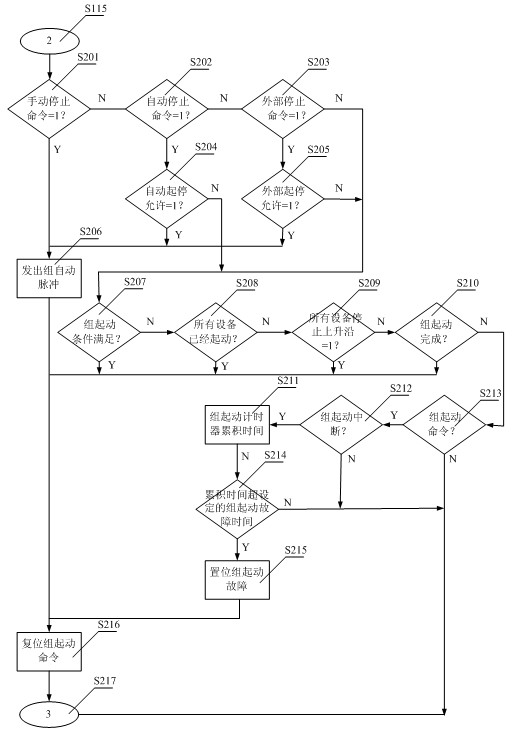

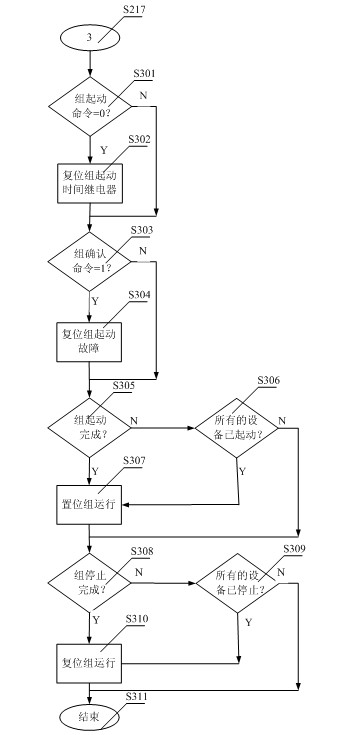

[0029] like figure 1 As shown, the group control system of multi-process start-stop control consists of the control core composed of the upper computer 1 that displays the group control status, configures the group control parameters, and the group control screen, and the lower computer 2 that executes the group control logic. Bus 2 collects status information of the controlled device and sends control commands to the controlled device. The group control screen is divided into a single process flow group control screen and a multi-process process group control screen, and the display screens are as follows: Figure 7 and Figure 8 As shown.

[0030] The upper computer 1 configures the values of the parameters in the group start-stop module in the lower computer through the group control screen, the configuration screen is as follows Figure 7 and Figure 8 shown. The operator realizes the group start and stop control of a single process flow through the single process f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com