Long-term preservation method for well core

A technology for drilling cores and preservation methods, which is applied in the field of core preservation and long-term preservation of drilling cores, which can solve problems such as difficulty in preservation, and achieve the effects of recovering economic losses, small physical and chemical properties, and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of casting materials:

[0031] Under normal temperature and pressure, slowly add the cobalt water isooctanoic acid cobalt styrene solution into the container containing crystal glue and stir evenly, the volume ratio of crystal glue and isooctanoate cobalt styrene solution is 100:0.3; slowly add methyl ethyl ketone peroxide Stir the newly prepared crystal glue and cobalt styrene isooctanoate mixed liquid container evenly to obtain a casting material, wherein the volume ratio of crystal glue and cobalt styrene isooctanoate mixed liquid to methyl ethyl ketone peroxide is 100:0.6.

[0032] (2) Implementation process:

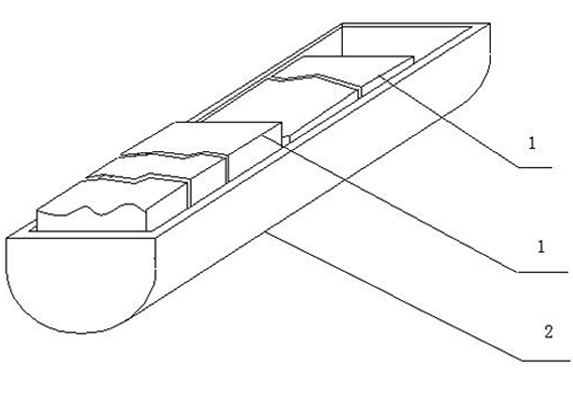

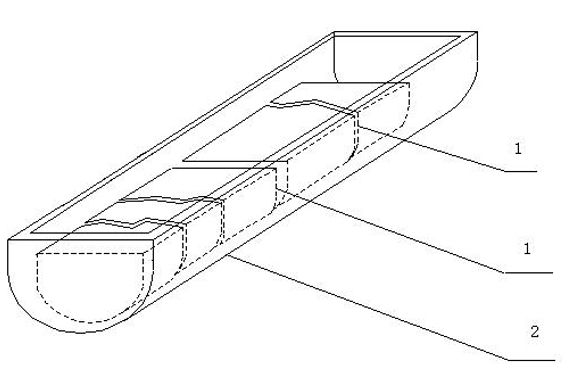

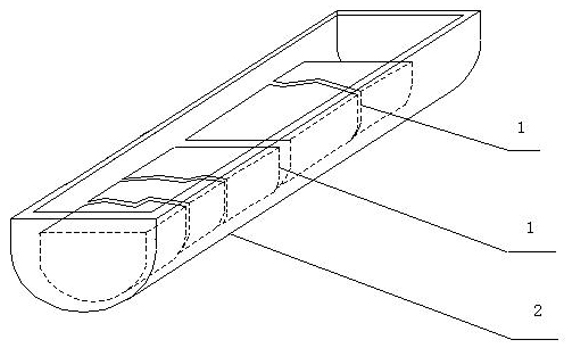

[0033] Such as figure 1 As shown, after the butt joint of the core to be preserved is in the original state, it is placed in a polyethylene U-shaped bracket, and the casting material prepared in the above (1) step is slowly poured into the polyethylene U-shaped bracket containing the core 1 In the groove 2, it should not be too fast, and...

Embodiment 2

[0036] (1) Preparation of casting materials:

[0037] Under normal temperature and pressure, slowly add cobalt water cobalt naphthenate into the container containing crystal gel and stir evenly. The volume ratio of crystal gel and cobalt naphthenate is 100:0.4; slowly add methyl ethyl ketone peroxide to the Stir evenly in the crystal glue and cobalt naphthenate mixed liquid container to obtain a casting material, wherein the volume ratio of the crystal glue and cobalt naphthenate mixed liquid to the volume ratio of methyl ethyl ketone peroxide is 100:0.8;

[0038] (2) Implementation process:

[0039] After the core stubble to be preserved is in the original state, put it into a polyethylene U-shaped bracket, and slowly pour the casting material prepared in the above (1) step into the polyethylene U-shaped bracket containing the core. If it is too fast, try to discharge all the air bubbles inside; place the core sample at room temperature for 14 hours after casting, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com