Polycrystalline silicon producing device

A technology for production equipment and polysilicon, applied in the direction of silicon and other directions, can solve the problems of pollution of production equipment, large temperature range of decomposition reaction, reduction of silane conversion rate, etc., and achieve the effects of reducing growth, improving conversion rate and purity, and reducing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with preferred specific embodiments.

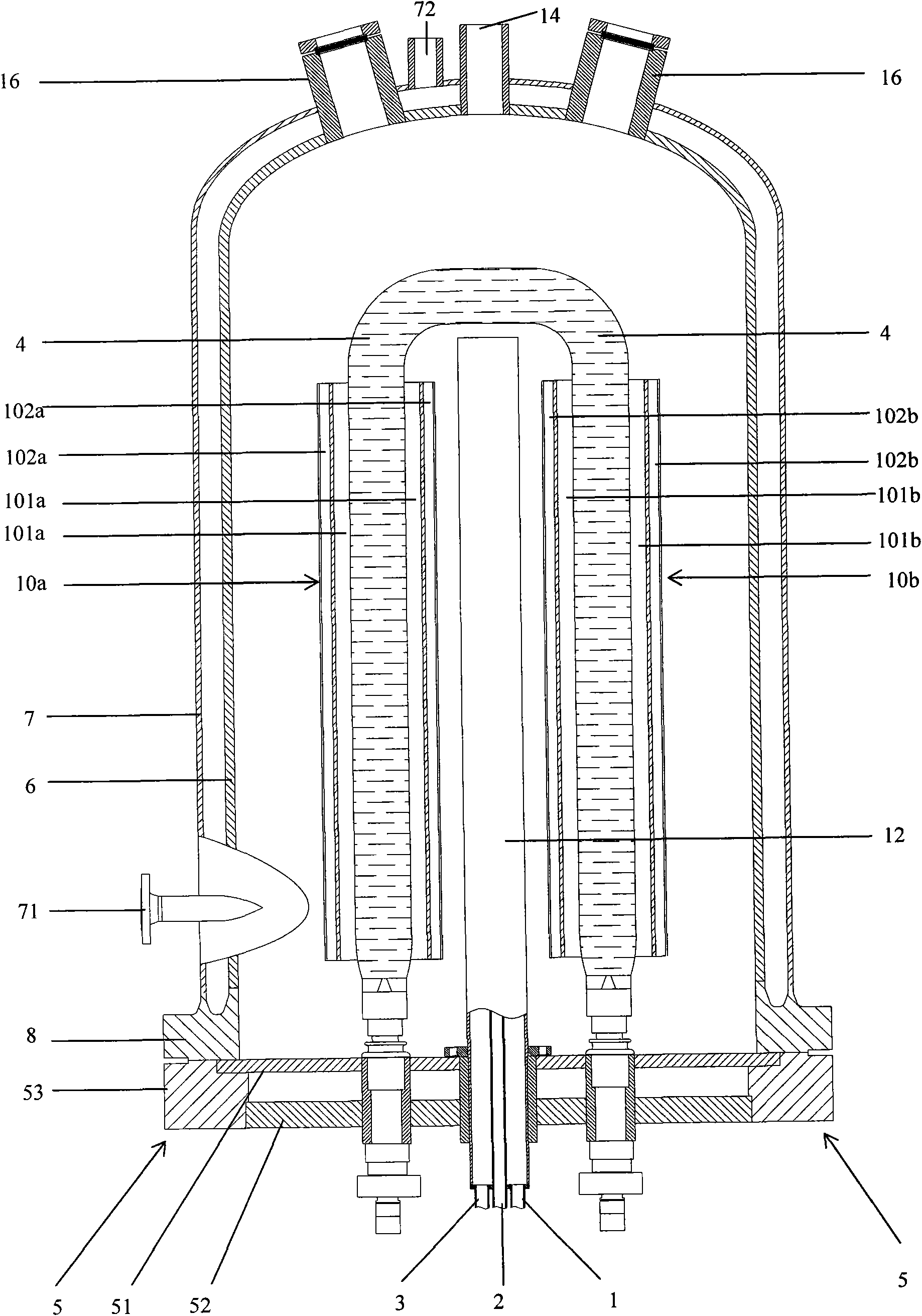

[0036] Combine figure 1 with figure 2 , The polysilicon production device of the present invention includes a chassis 5, a bell jar 6 arranged on the upper part of the chassis 5, and the bell jar 6 and the chassis 5 form a reactor. A tail gas outlet 14 is provided on the top of the bell 6 and two sight glasses 16 are provided on the upper portion of the bell 6.

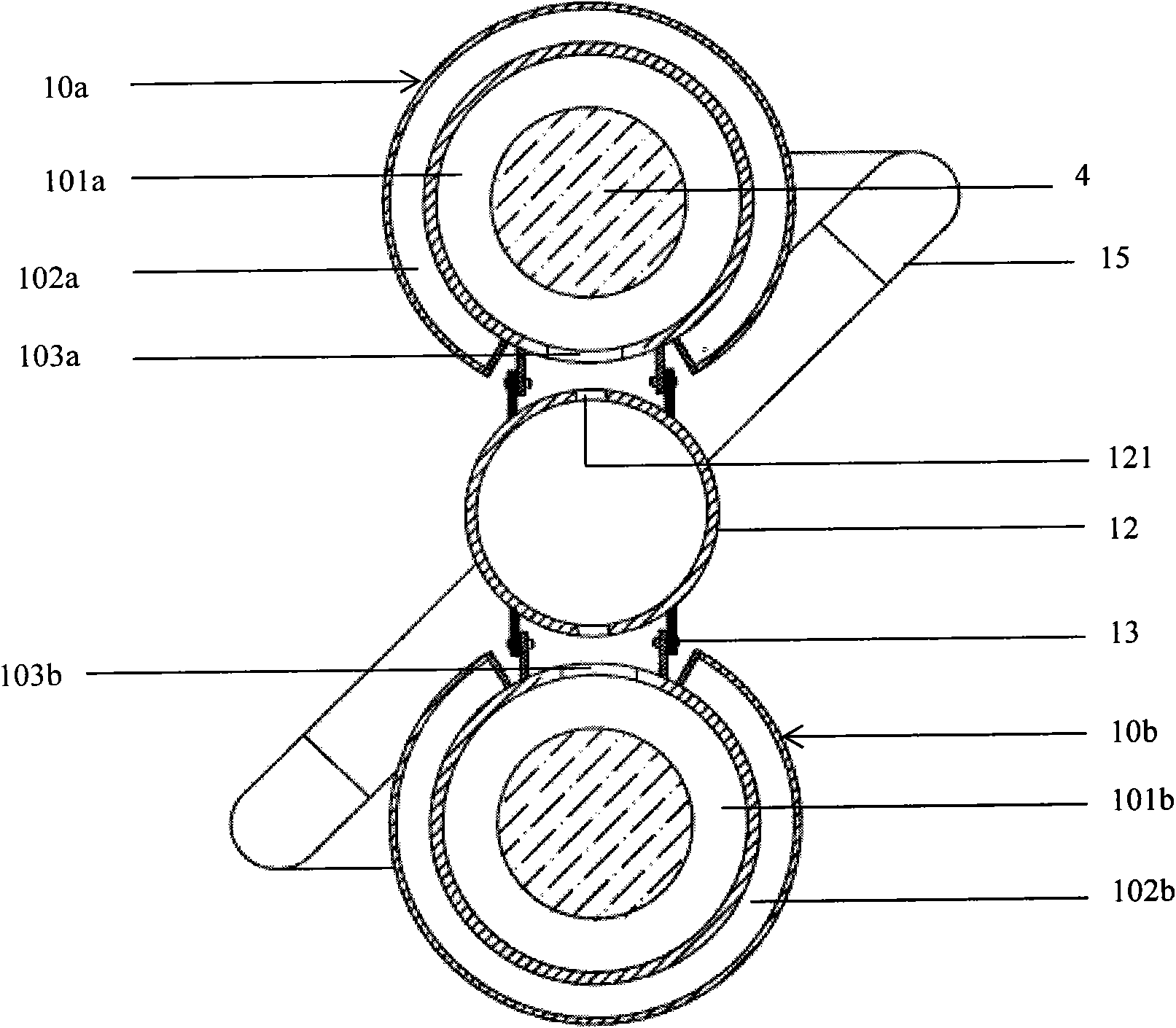

[0037] A set of internals are arranged inside the reactor, the internals include two identical jacketed tubes 10a, jacketed tubes 10b, and a middle tube 12, and a connecting piece 13 and a connecting tube 15 connecting the middle tube and the jacketed tube A polysilicon rod 4 is arranged in each jacket tube, and two polysilicon rods 4 pass through the jacket tube 10a and are connected to the top of the jacket tube 10b to form a pair of polysilicon rods.

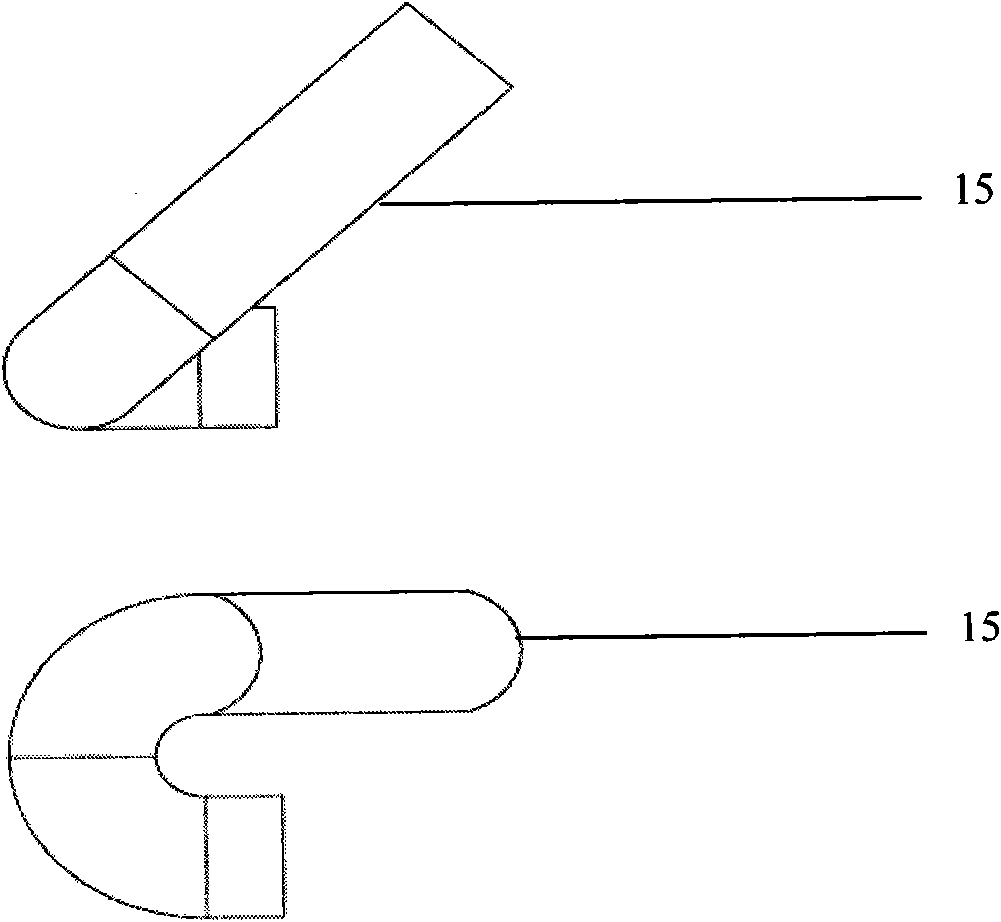

[0038] Combine figure 2 with image 3 The jacket tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com