Auxiliary electrode structure for organic light emitting diode (OLED) illuminating panel

An auxiliary electrode and panel technology, applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of improving the brightness uniformity of the panel, reducing the light transmission area of the panel, reducing the aperture ratio of the panel, etc., so as to improve the uniformity of brightness performance, extended device life, and slowed down material aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

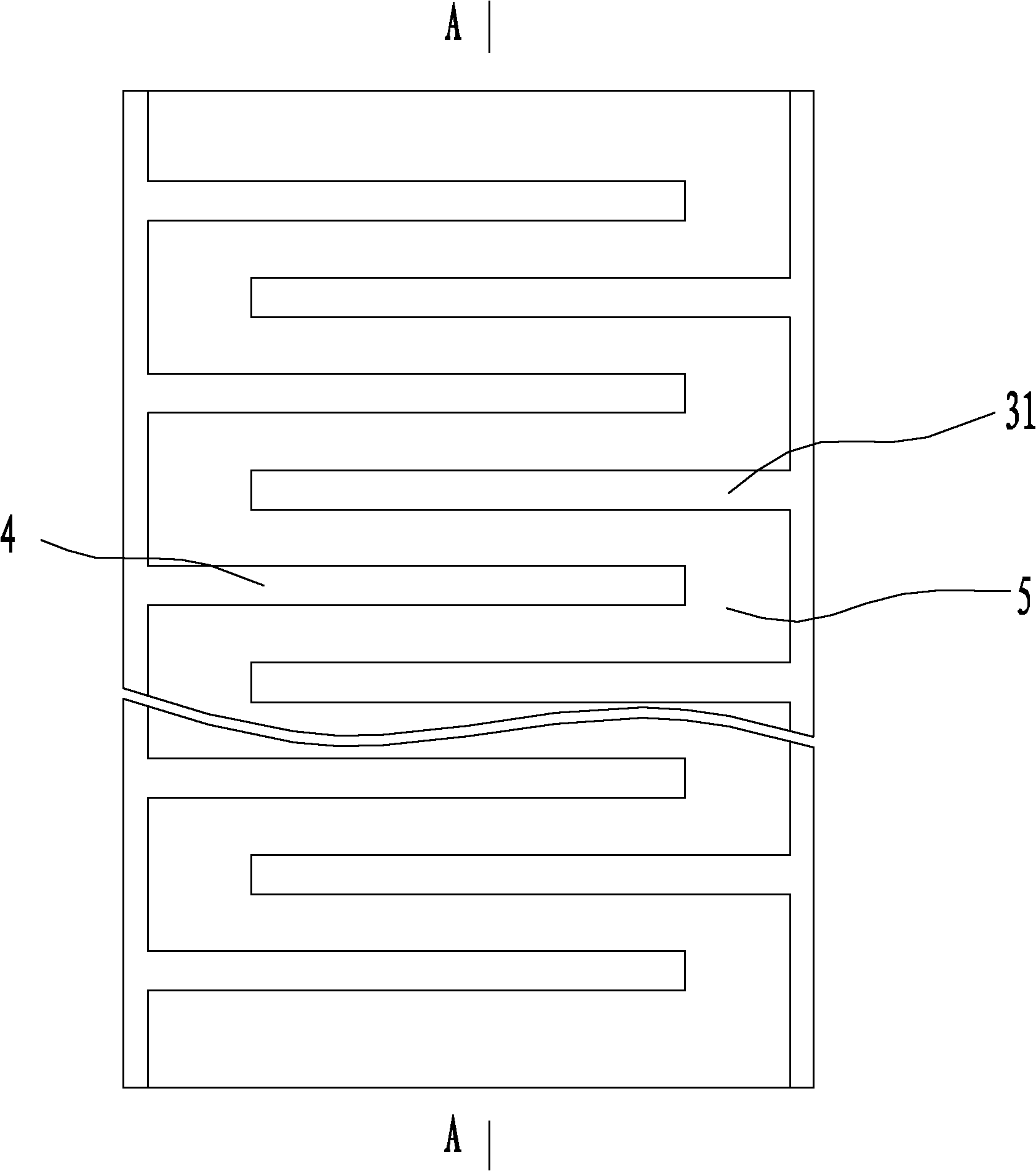

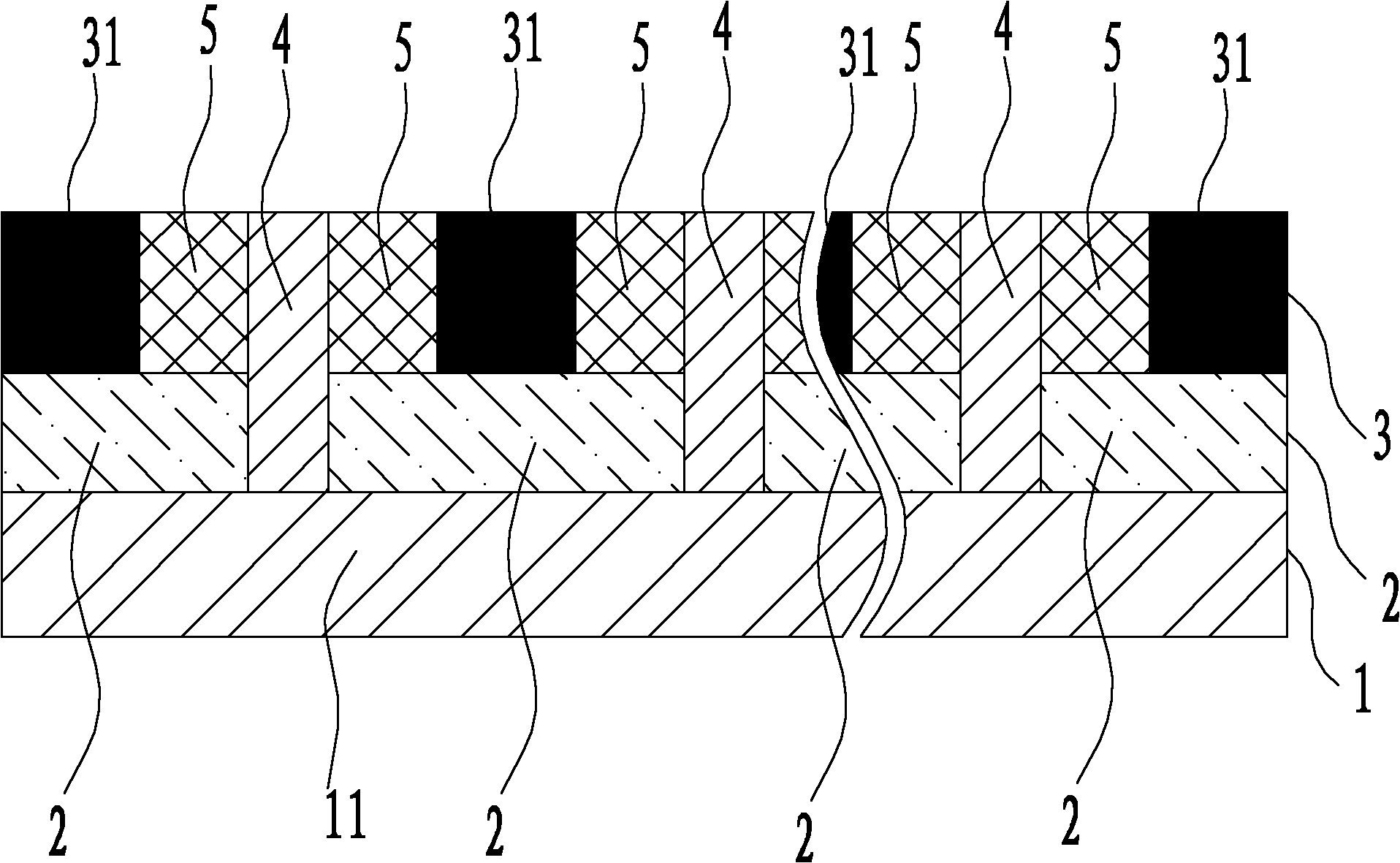

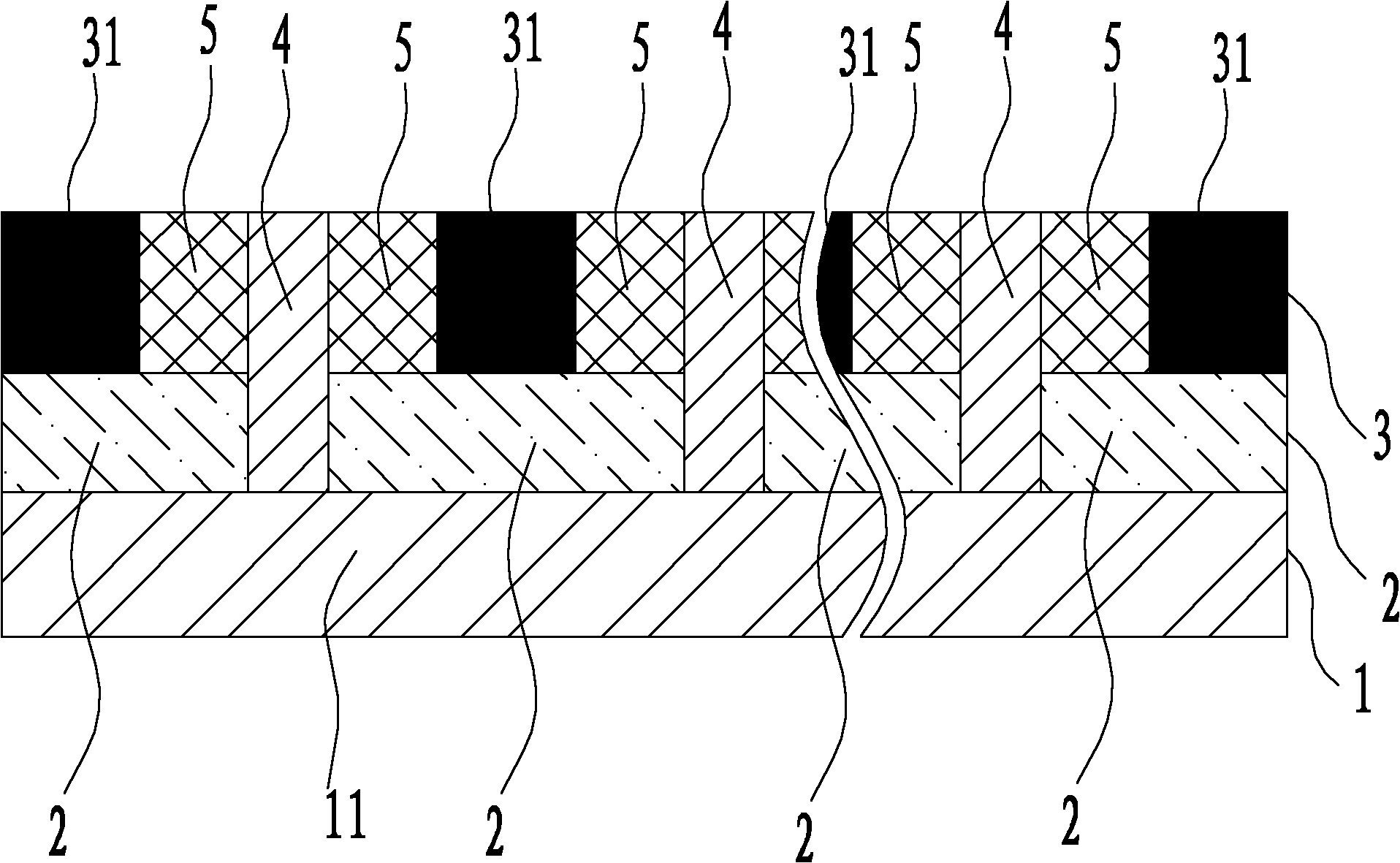

[0011] Such as figure 1 , figure 2 Shown is an auxiliary electrode structure for OLED lighting panels with small impedance, small current voltage drop, and high brightness uniformity provided by the present invention. The auxiliary electrode structure includes an anode layer 1 at the bottom, a cathode layer 3 at the top, a luminescent layer 2 between the anode layer 1 and the cathode layer 3, and an auxiliary electrode 4. The anode layer 1 is made of transparent The anode 11 is formed, the cathode layer is composed of a metal cathode 31, and the auxiliary electrodes 4 themselves communicate with each other and communicate with the transparent anode 11. It is characterized in that: the auxiliary electrode 4 passes through the light emitting layer 2 and extend into the cathode layer 3 ; between the auxiliary electrode 4 and the metal cathode 31 there is an insulating spacer column 5 separating the auxiliary electrode 4 from the metal cathode 31 . Like this, by thickening the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com