Method and apparatus for gas-solid separation, application to polymerization reactions

A technology of gas-solid separation and separation chamber, which is applied in the direction of separation method, device whose axial direction of swirl flow can be reversed, swirl flow device, etc., and can solve problems such as increasing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

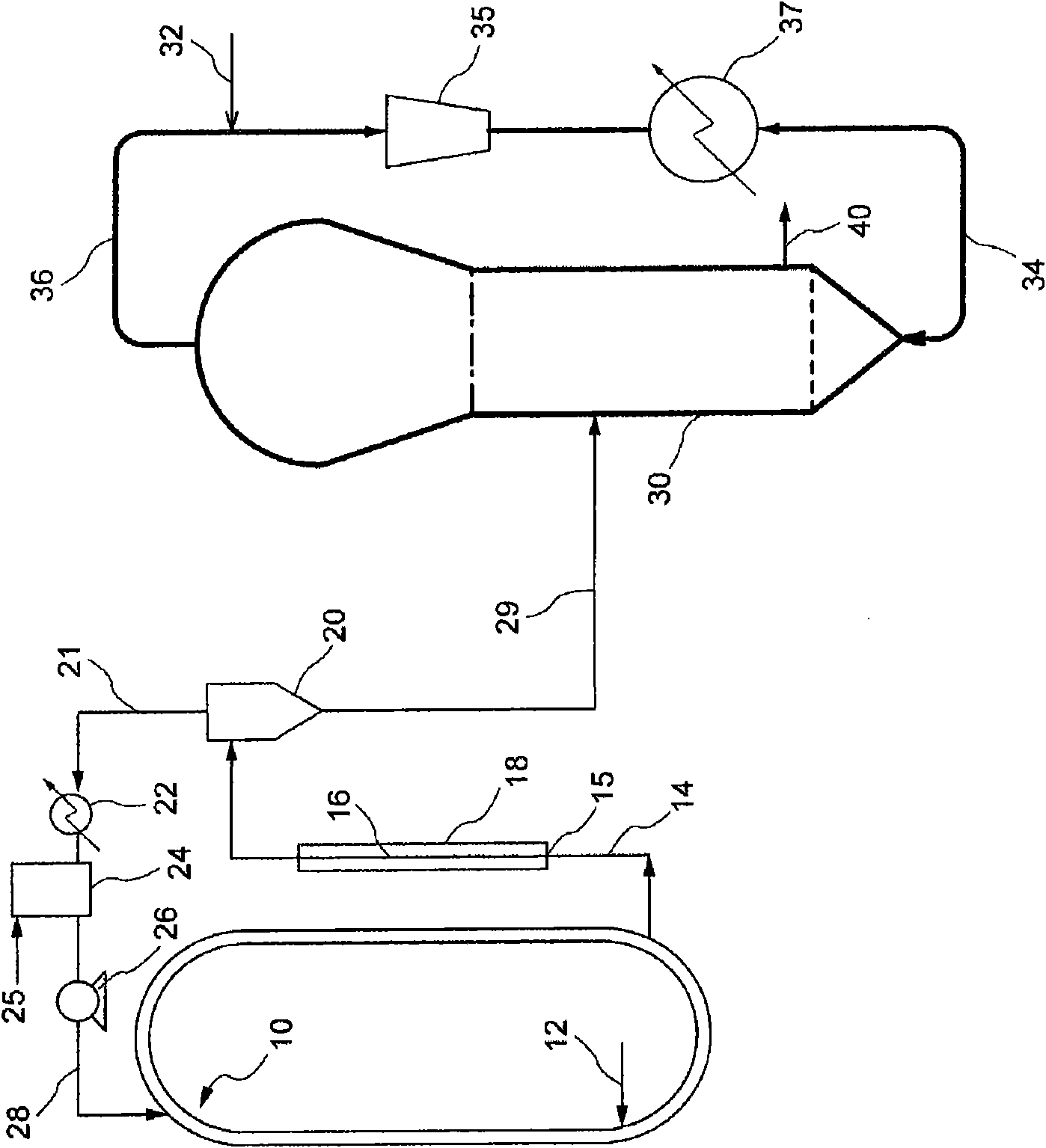

[0018] exist figure 1 In an embodiment, the slurry polymerization is carried out in a jacketed loop reactor, designated 10. Schematically, catalyst components, co-catalysts, and monomers (such as propylene) are introduced into the loop reactor in the direction indicated by arrow 12 . Including loaded with active MgCl 2 In cases where a Ziegler / Natta catalyst on a solid component is used, the solid component can be fed in as such or, preferably, in prepolymerized form.

[0019] Loop reactor 10 may be the first polymerization reactor of the process, or there may be other polymerization reactors upstream of reactor 10 . For purposes of the present description, reactor 10 may receive from line 12 polymer produced in other reactors, or receive prepolymer and / or polymerization catalyst or catalyst components. exist figure 1 The feed lines for catalyst, monomer, molecular weight regulator and other possible ingredients have been omitted in the simplified diagram of , since they a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com