A/O reactor with functions of air lift, backflow as well as rotation and mixing of reflux

A reflux liquid and reactor technology, applied in the field of A/O reactors, can solve the problems of increased power consumption, large floor space, and high construction funds, and achieve the advantages of saving operating costs, saving floor space, and improving effluent quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

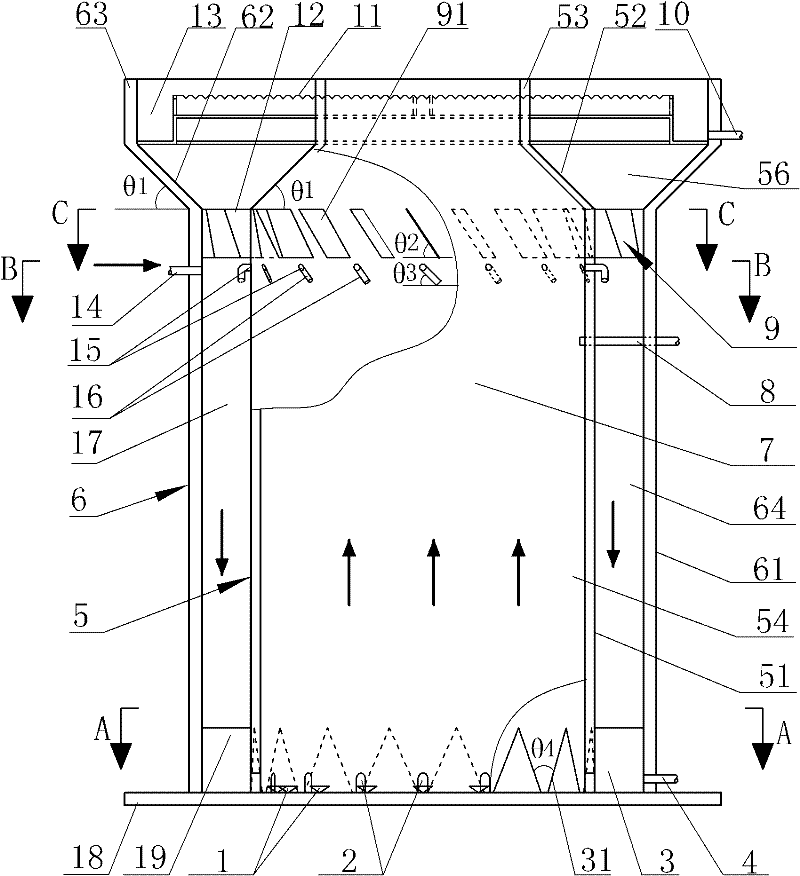

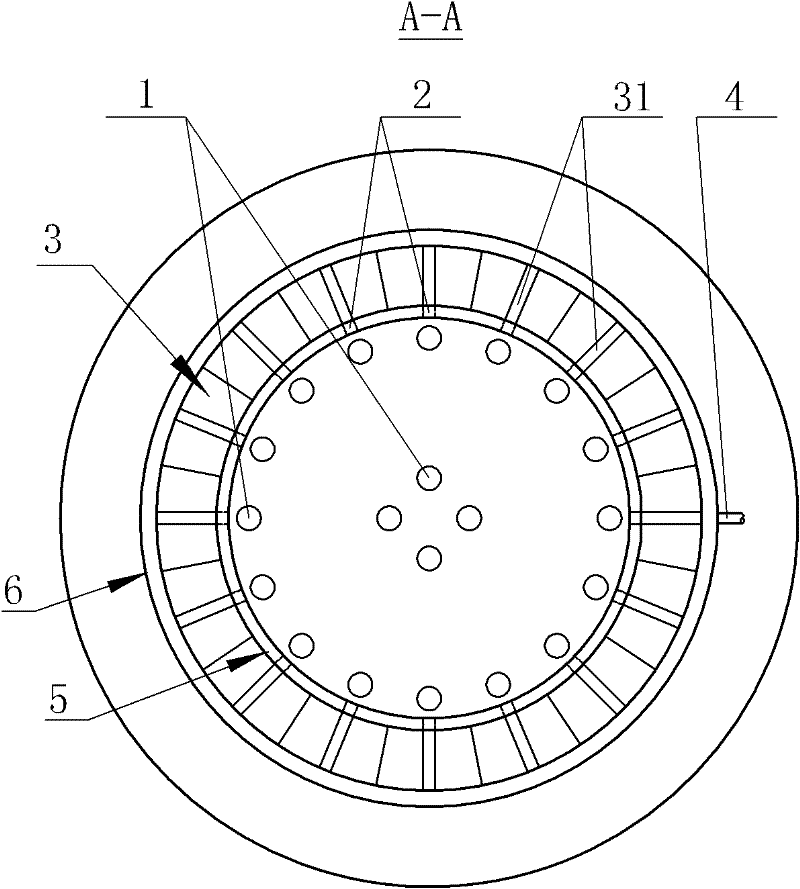

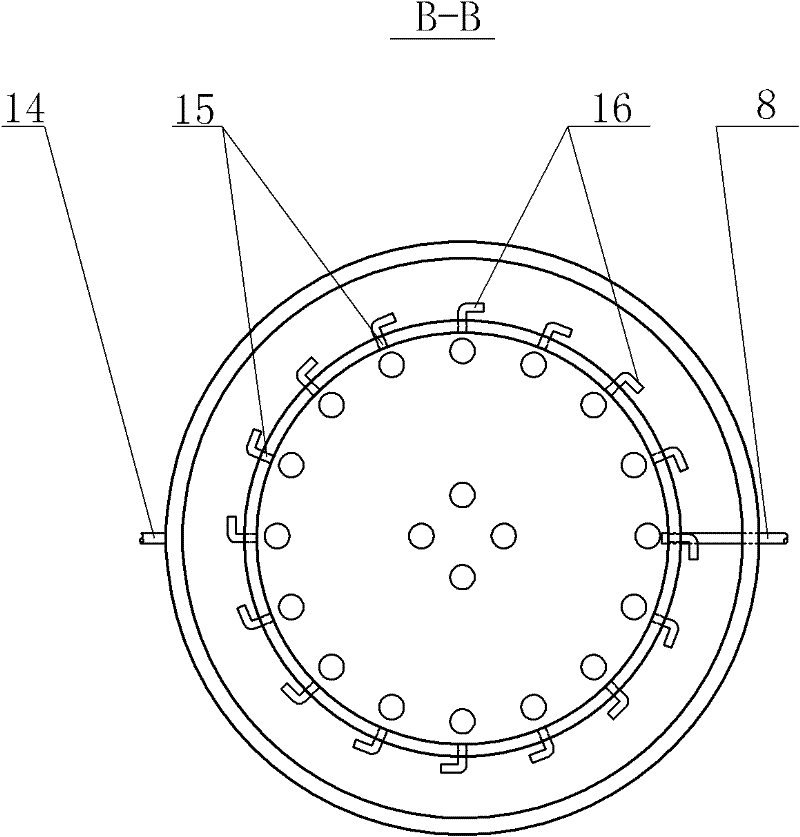

[0021] Figure 1-Figure 5 It shows an A / O reactor with gas-lift reflux and rotating mixed reflux liquid, including container body, aerobic zone with microporous aerator group, anoxic zone, solid-liquid separation and clarification zone, water inlet pipe, collection The water weir, water collection tank, outlet pipe and mixed liquid discharge pipe are characterized in that the container body is composed of a barrel-shaped inner barrel wall 5 and a barrel-shaped outer barrel wall 6, which are coaxially set and fixed on the same bottom plate 18 with intervals, The container body is divided into a barrel-shaped inner barrel body 54 and an annular outer barrel body 64 by the inner barrel wall 5. The inner barrel wall 5 includes a cylindrical inner barrel wall 51 connected in sequence from bottom to top, an inwardly tapered barrel wall 52 and a circular inner barrel mouth 53. Three parts; the above-mentioned outer barrel wall 6 and the inner barrel wall respectively include three pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com