Fireproof smoke discharging air passage

A technology of smoke and fireproof materials, applied in fire prevention, vertical pipes, building components, etc., can solve the problems of inability to manufacture curved structures, fail to meet environmental protection requirements, affect reliability of use, etc., and achieve consistent overall reliability , overall light weight and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Prepare the slurry of the fireproof material according to the prescribed ratio;

[0029] (2) Make the mold according to the requirements;

[0030] (3), inject the slurry into the mould;

[0031] (4), demoulding after hardening;

[0032] (5), maintenance;

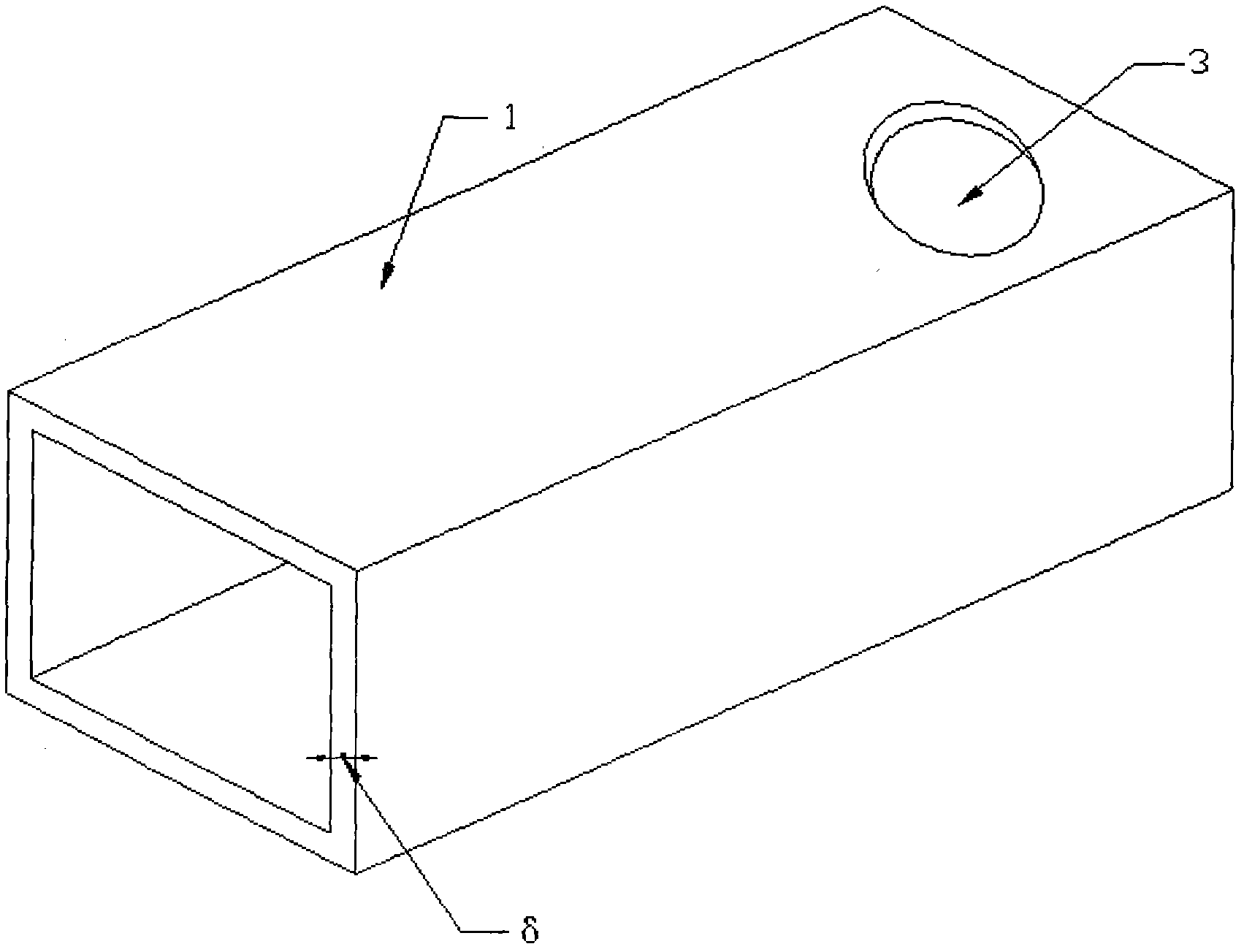

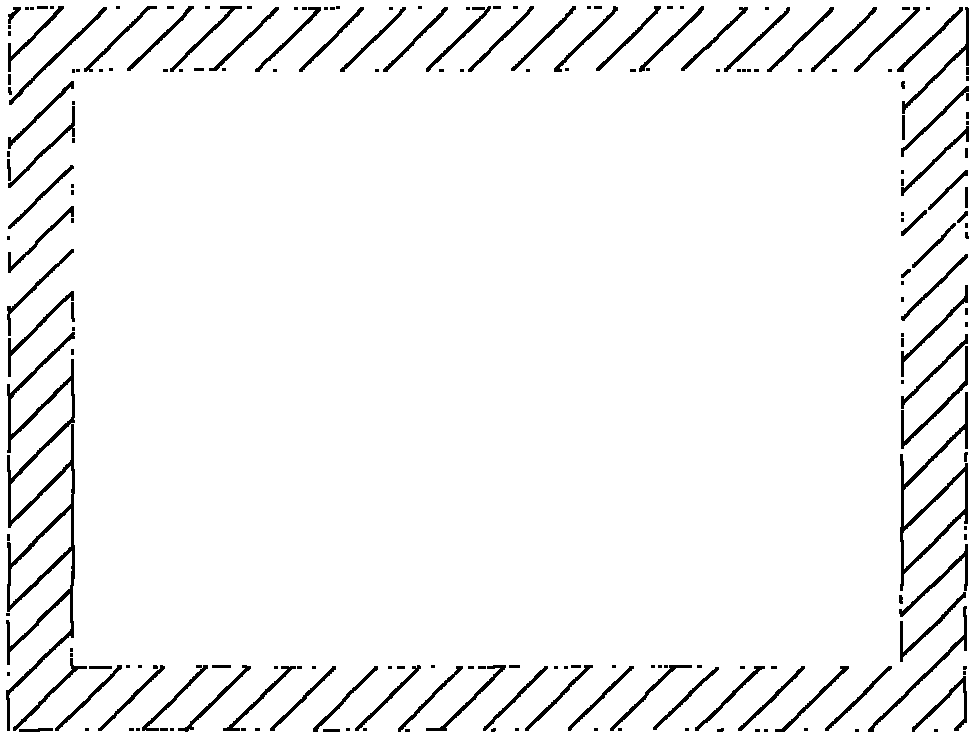

[0033] (6) Finished product: the prepared fireproof smoke exhaust duct has a size of 500mm×250mm×2000mm and a wall thickness of 15mm.

Embodiment 2

[0035] (1) Prepare the slurry of the fireproof material according to the prescribed ratio;

[0036] (2), the slurry is sent to the extrusion molding machine, and the backlog is formed;

[0037] (3), maintenance;

[0038] (4) Finished product: the prepared fireproof flue gas duct has a size of 250mm×350mm×2900mm and a wall thickness of 12mm.

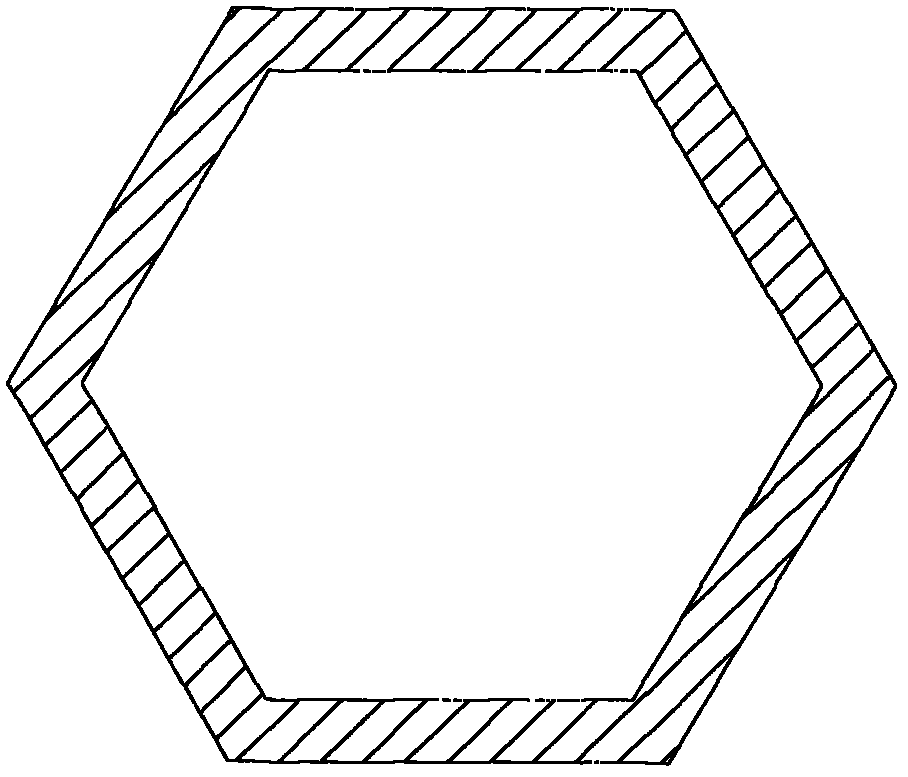

[0039] The fire-resistant smoke exhaust duct of the present invention can be molded integrally or extruded integrally. Extrusion molding is suitable for large-scale large-scale production, and the mold molding method is more flexible, and the requirements for equipment and fireproof materials are not high. Suitable for promotional use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com