Hydropower generation variable speed gear

A speed change device, high-speed shaft technology, applied in the transmission device, transmission device parts, gear transmission device, etc., to achieve the effect of reliable use, small local resistance coefficient and good lubrication performance

Active Publication Date: 2013-06-12

STATE GRID CORP OF CHINA +1

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(A) It is not creative to introduce the "oil injection ball top" to lubricate the meshing part of the inner gear sleeve, because the inner gear sleeve is just a coupling, the relative rotation between the meshing parts is extremely small, and the oil splashed by the transmission parts is enough to lubricate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

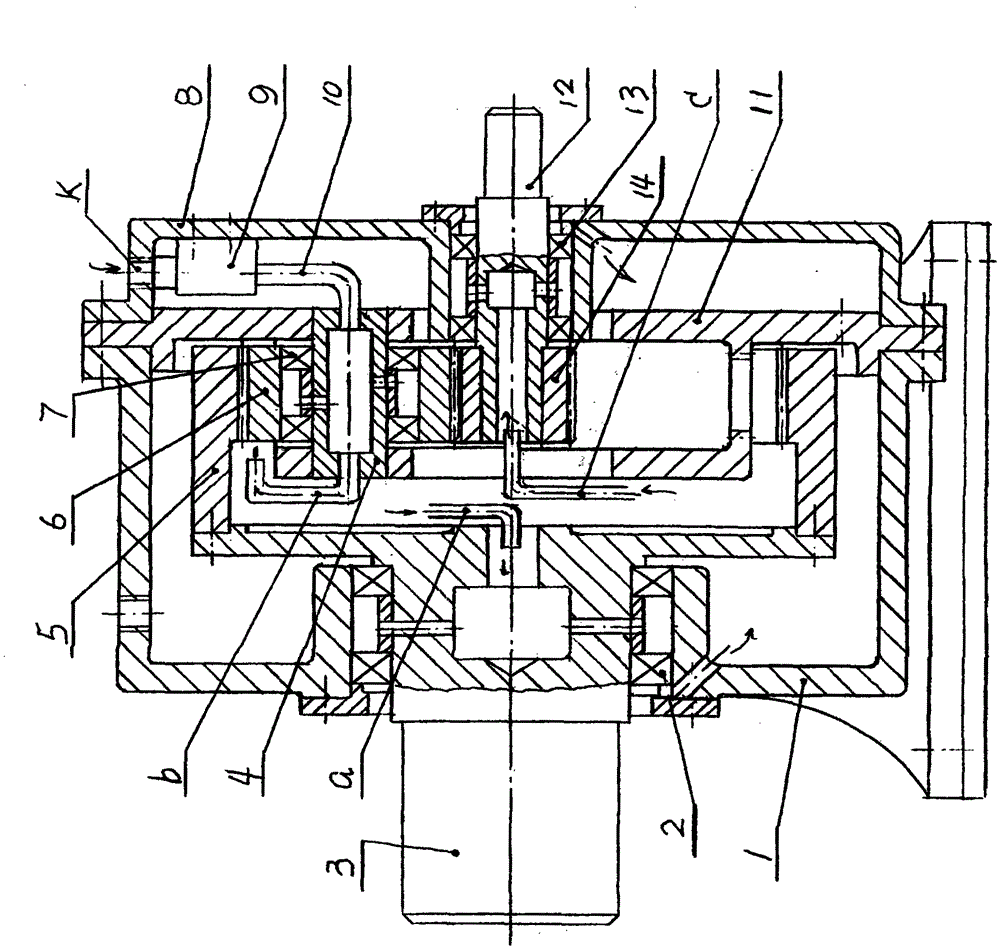

The invention relates to the technical field of acceleration in variable transmission, in particular to a hydropower generation variable speed gear. The hydropower generation variable speed gear comprises a high-speed shaft, a sun gear, a quasi-planet gear, planet gear axles, a big end cover, a fixed frame, an inner gear ring, a low-speed shaft and a base, wherein, the big end cover is sequentially connected with the fixed frame and the end surface of the input end of the base, and the three uniformly-distributed planet gear axles are fixed on the frame. The hydropower generation variable speed gear is characterized in that (A) the big end cover is equipped with an oil inlet screw hole K, one end of the screw hole is connected with a lubricating oil station, the other end of the screw hole is connected with a lubricating oil distributor, and three oil outlet pipes of the distributor are respectively connected on one end of each hollow planet gear axle; (B) the other ends of the three hollow planet gear axles are connected with an oil pipe a, an oil pipe b and an oil pipe c which respectively point to the blind holes of the low-speed shaft, the meshed position between the inner gear ring and the planet gear, and blind holes of the high-speed shaft so as to facilitate lubricating the meshed position between bearings and internal teeth; and (C) the main body of the base is an integral cast thin-wall cylinder. The hydropower generation variable speed gear has the following beneficial effects: (a) local resistance coefficient zeta of a lubricating system is small, and the lubricating property of the meshed positions is good; and (b) the integral cast cylinder base with no need of disassembly in the case of maintenance is adopted in the variable speed gear, thus the device has the advantages of high mechanical strength, good rigidity, light, uniform and thin wall with rational stress distribution, good processing property and applicability to quantity production.

Description

【Technical field】 The invention relates to the technical field of speed-up in variable-speed transmission, and relates to a speed-changing device for hydroelectric power generation. 【Background technique】 Tailong Group Company's "Hydraulic Power Generation Transmission Device" (ZL200810022394) belongs to NGW planetary transmission, and has obtained the invention patent right due to the following improvements: (1) Introducing "oil injection dome" to lubricate the meshing part of the inner gear sleeve; (2) In order to It is easy to disassemble and assemble during maintenance in remote mountainous areas. However, the main problems of changing the traditional integral cylindrical base of the planetary gearbox into a split and welded base are: (A) The structure of introducing the "oil injection ball top" to lubricate the meshing part of the inner gear sleeve is not creative, because the inner gear sleeve is just a kind of coupling, the relative rotation between the meshing part...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16H3/44F16H57/04F16H57/08

CPCF16H3/72F16H57/0479

Inventor 吴声震

Owner STATE GRID CORP OF CHINA

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com