Large-torque hydraulic electrogenerating speed change device

A speed change device and high-torque technology, which is applied in the field of high-torque hydroelectric power generation speed change devices, can solve problems such as the unreasonable meshing of the oil-sprayed spherical top lubricated internal gear sleeves, and achieve the effects of light weight, good rigidity, and improved load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

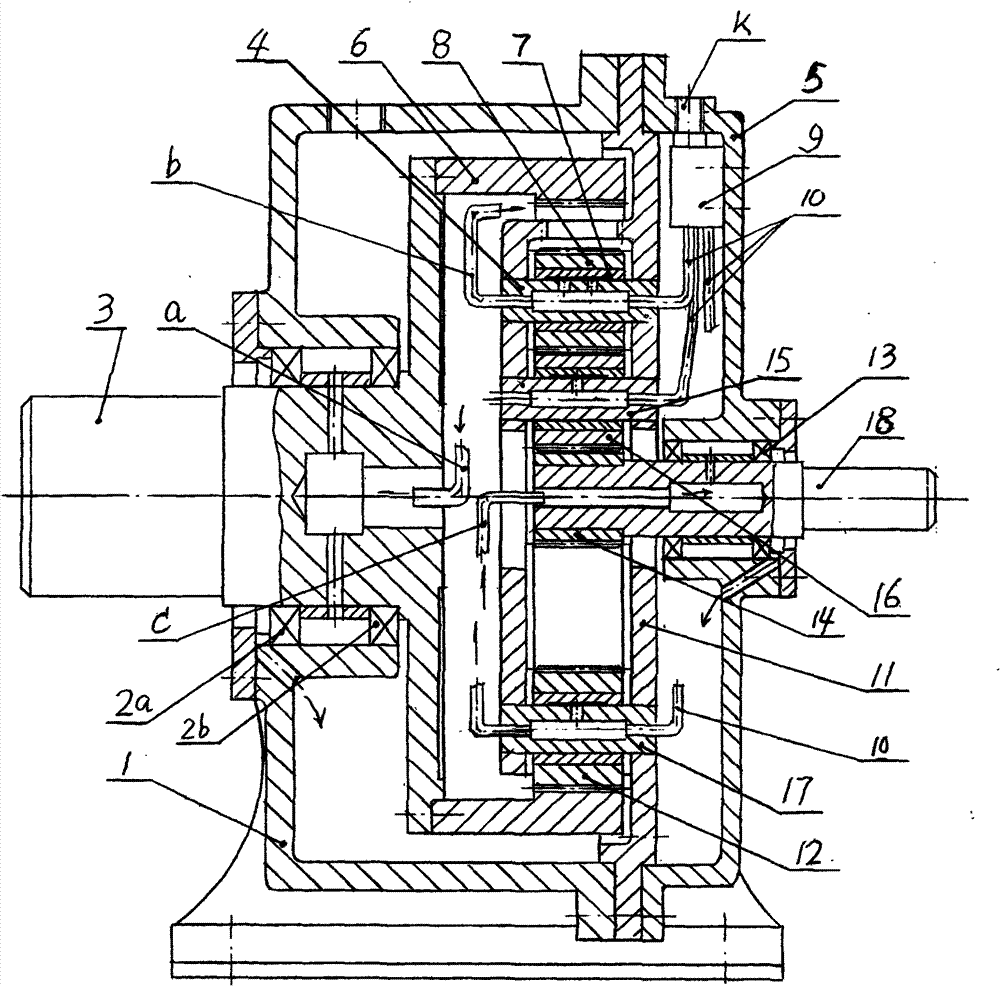

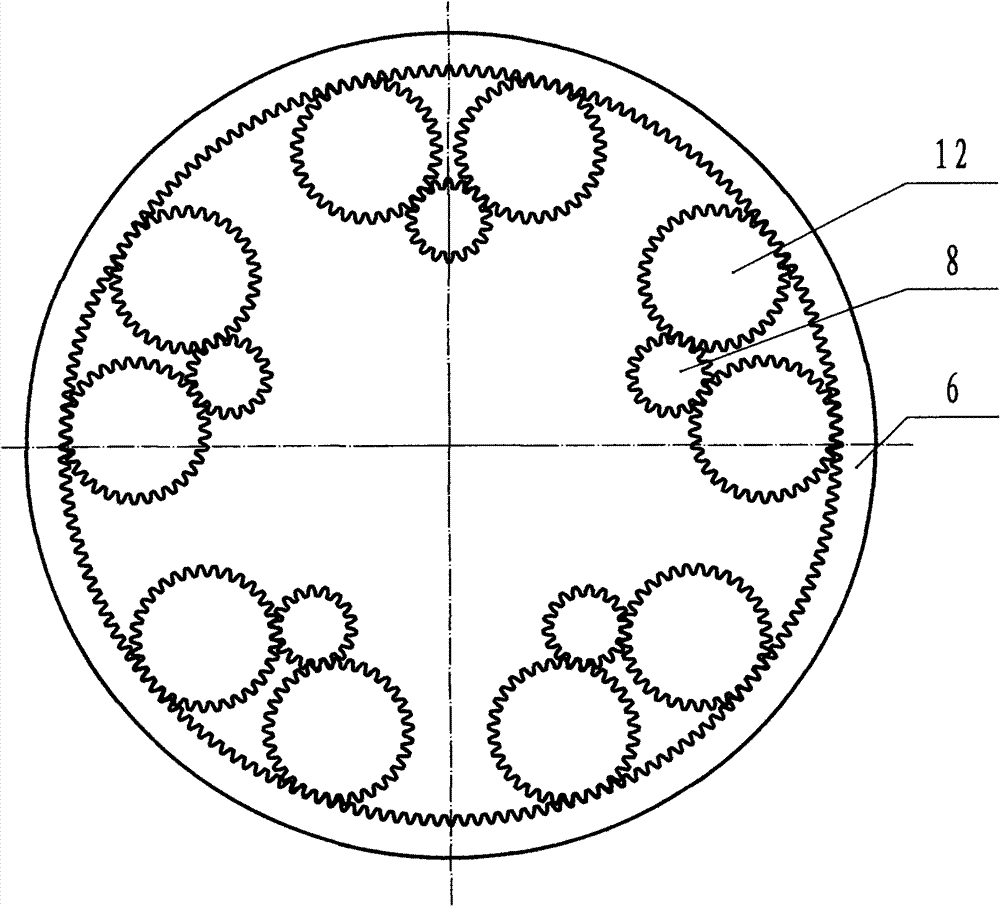

[0015] see figure 1 .and 2. a high-torque hydroelectric power transmission device, comprising a base 1, a high-speed shaft 18, two first support bearings 13, a sun gear 14 mounted on the high-speed shaft 18, and 3-5 evenly distributed quasi-planets Wheel 8, sliding bearing 7, hollow planetary wheel shaft 4, large end cover 5, fixed frame 11, inner ring gear (6), two second supporting bearings (2a, 2b) of low-speed shaft 3, large end cover 5 and The fixed frame 11 and the input end face of the frame 1 are connected, and the hollow planetary wheel shaft 4 is fixed on the frame 11, and the input from the low-speed shaft and the inner ring gear 6 to the output of the sun gear 14 and the high-speed shaft 18 is a single-stage speed increase. There is an intermediate wheel 16 between the sun gear 14 and the uniformly distributed 3-5 quasi-planetary gears 8, and the mandrel 15 of the intermediate wheel is fixed on the frame 11. Two identical splitter gears 12 arranged symmetrically o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com