Optimization design method for air conditioner airduct structure

An optimized design and air conditioner technology, which is applied in the direction of instruments, calculations, and special data processing applications, can solve the problems of shortened test time, long test cycle, and high production cost, so as to shorten the development cycle, improve R&D efficiency, and save production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

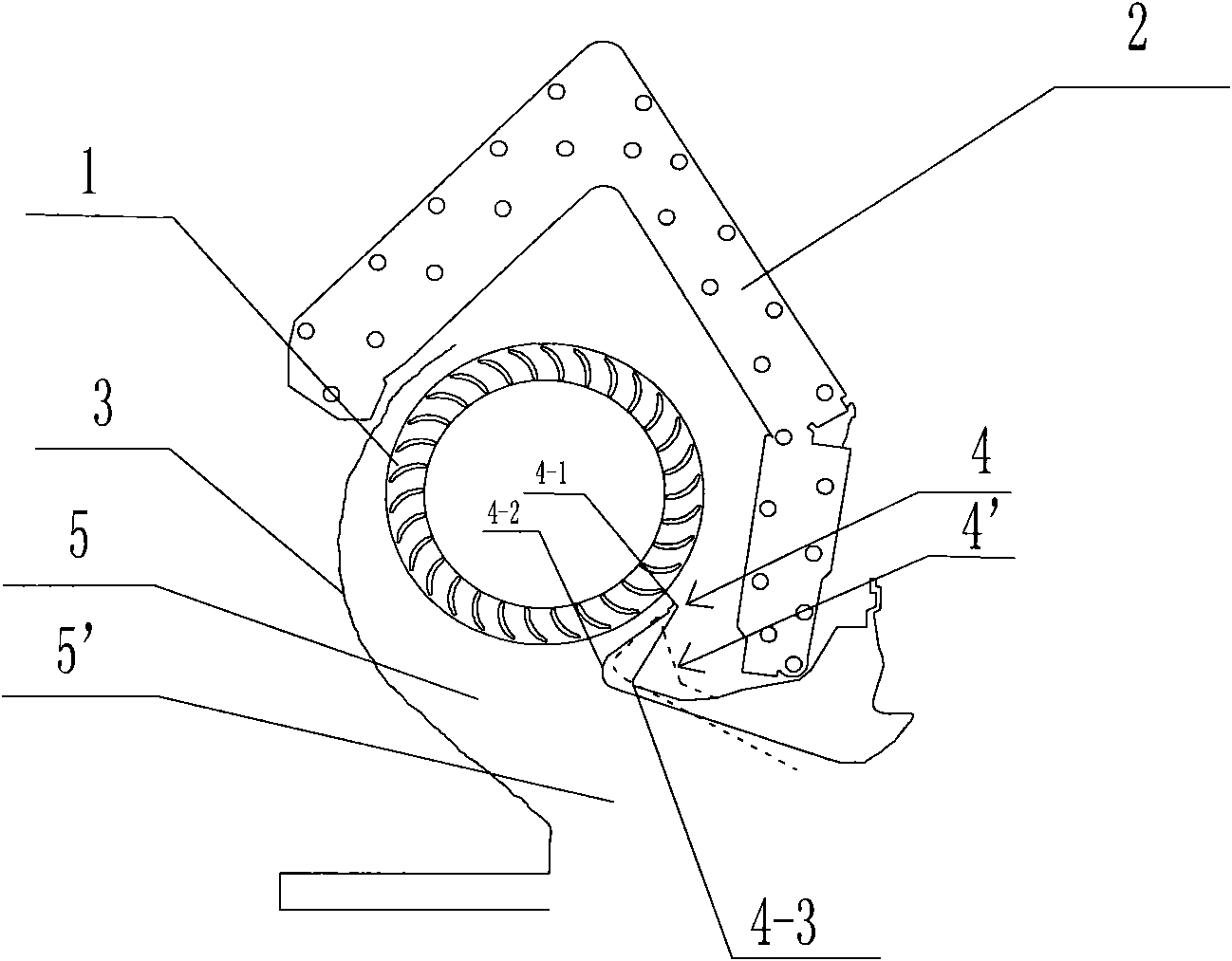

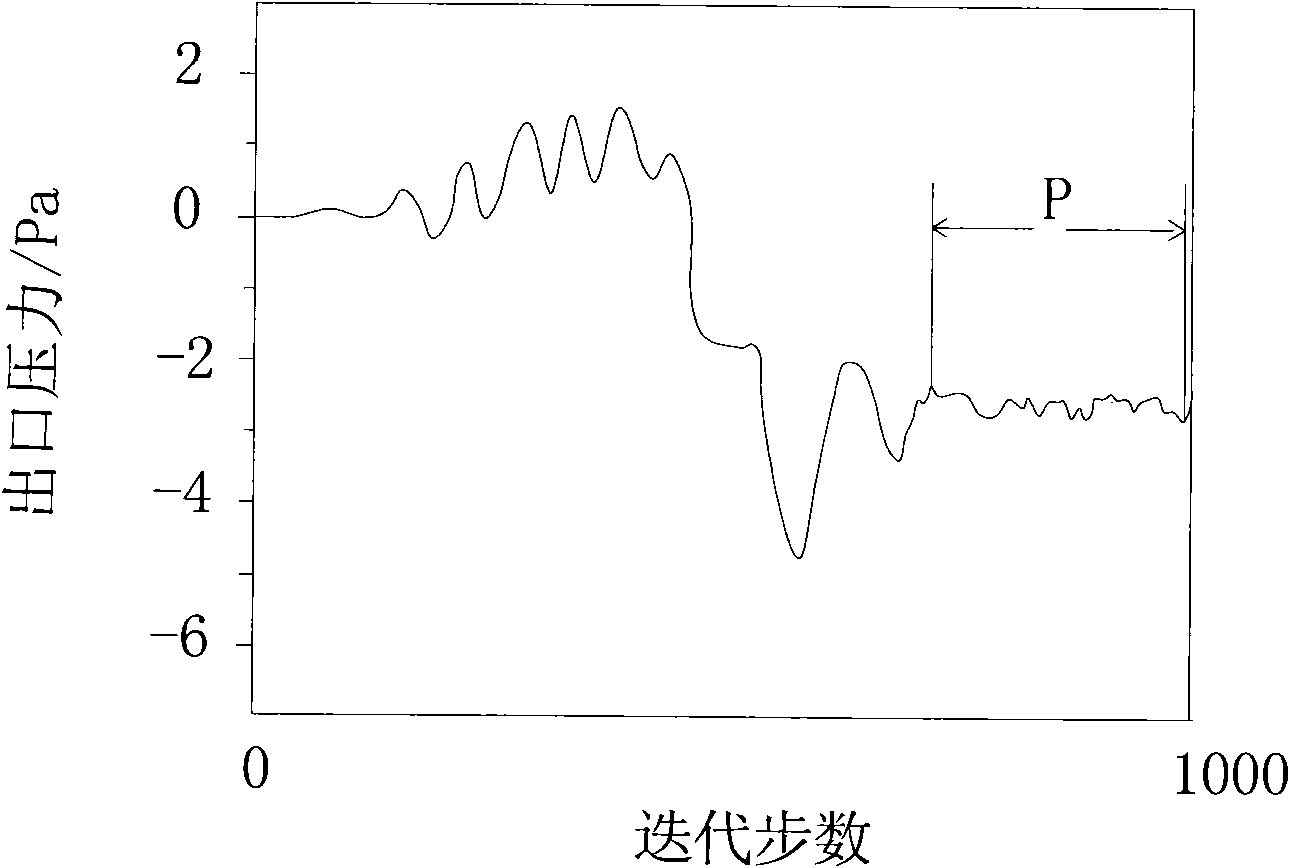

[0026] Embodiment one, see figure 1 As shown, for this embodiment, two air conditioner air duct models with different structures are first established by using PROE software, and the operating platform of the PROE software is a computer. In this embodiment, the air conditioner air duct model can specifically include four parts: evaporator, air duct, volute and volute tongue; wherein the air conditioner air duct model includes fan 1, evaporator 2, volute 3, and volute tongue 4, and the air duct 5 surrounded by the fan 1, the evaporator 2, the volute 3 and the volute tongue 4, for the convenience of describing the two air duct structures, this embodiment defines three characteristic points of the vortex tongue 4: the vortex tongue 4 Extending to the highest point 4-1 of the evaporator 2 part, the closest point 4-2 of the volute tongue 4 to the volute 3, and the farthest point 4-3 of the vortex tongue 4 to the fan 1. figure 1 Also includes air conditioner air duct model 2, inclu...

Embodiment 2

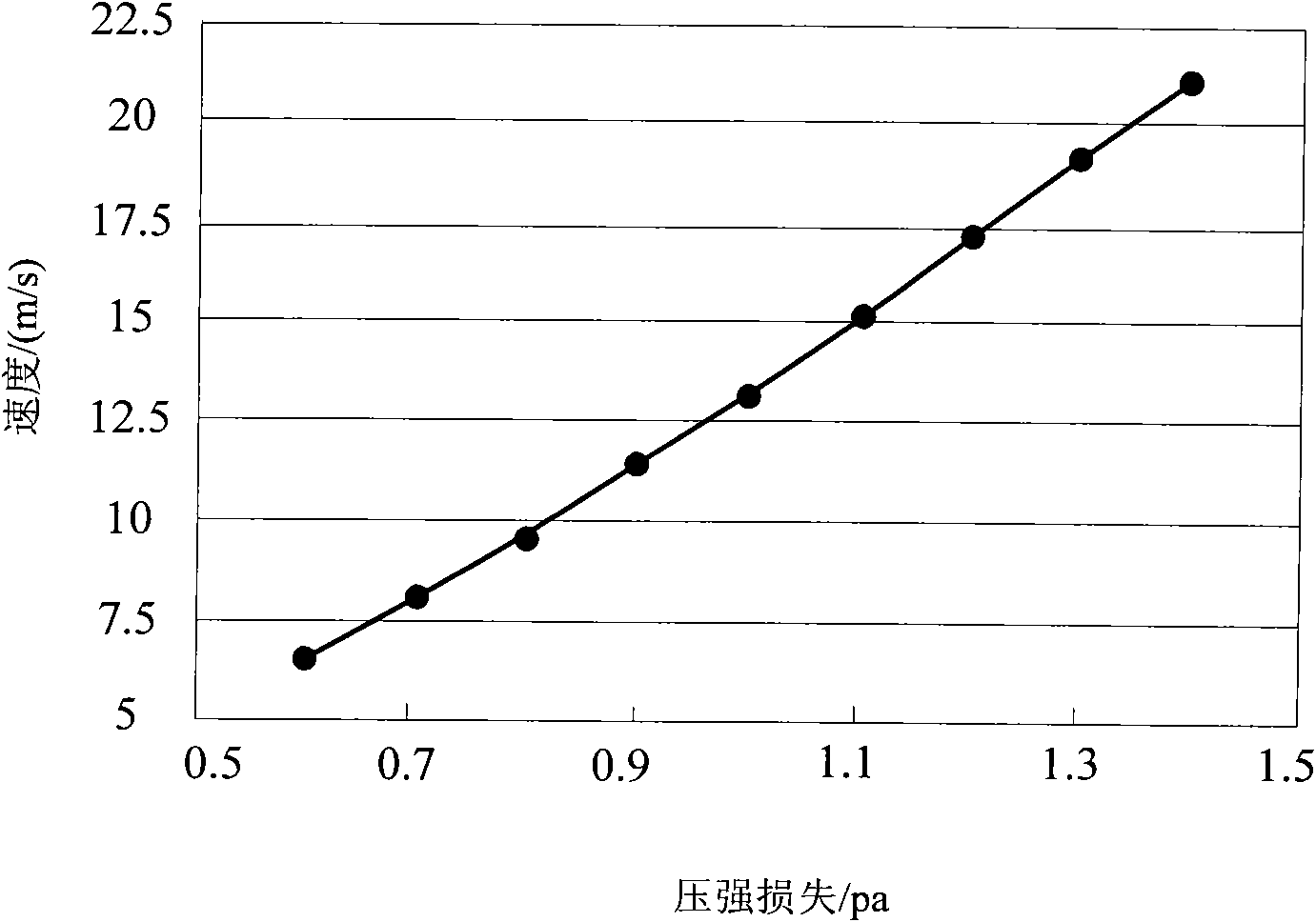

[0047] Embodiment two, see Figure 4 As shown, let the vortex tongue gap h be the distance between the fan 1 and the vortex tongue 4 . The difference between this embodiment and the first embodiment is that the structure of the volute tongue 4 is not changed, and the optimal design of the air duct structure of the air conditioner is realized by optimizing and improving the value of the volute tongue gap h.

[0048] First, use PROE software to establish two different air conditioner air duct models, which are respectively recorded as model 3 and model 4. The vortex tongue clearance h of the two air conditioner air duct models are 3mm and 4mm respectively. The import of generated files, the setting of model parameters and variable parameters, and the setting of other parameters are consistent with the operation method described in Embodiment 1, and will not be repeated here.

[0049] The noise of the two air conditioner air duct models and the air volume blown out of the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com