Drilling unit, method for slot drilling and slotting device

The technology of a drilling machine and impact device, which is applied to drilling equipment and methods, drill pipes, drill pipes, etc., can solve the problems of damage to the body and guide parts of the slotting device, and achieve the effect of long working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

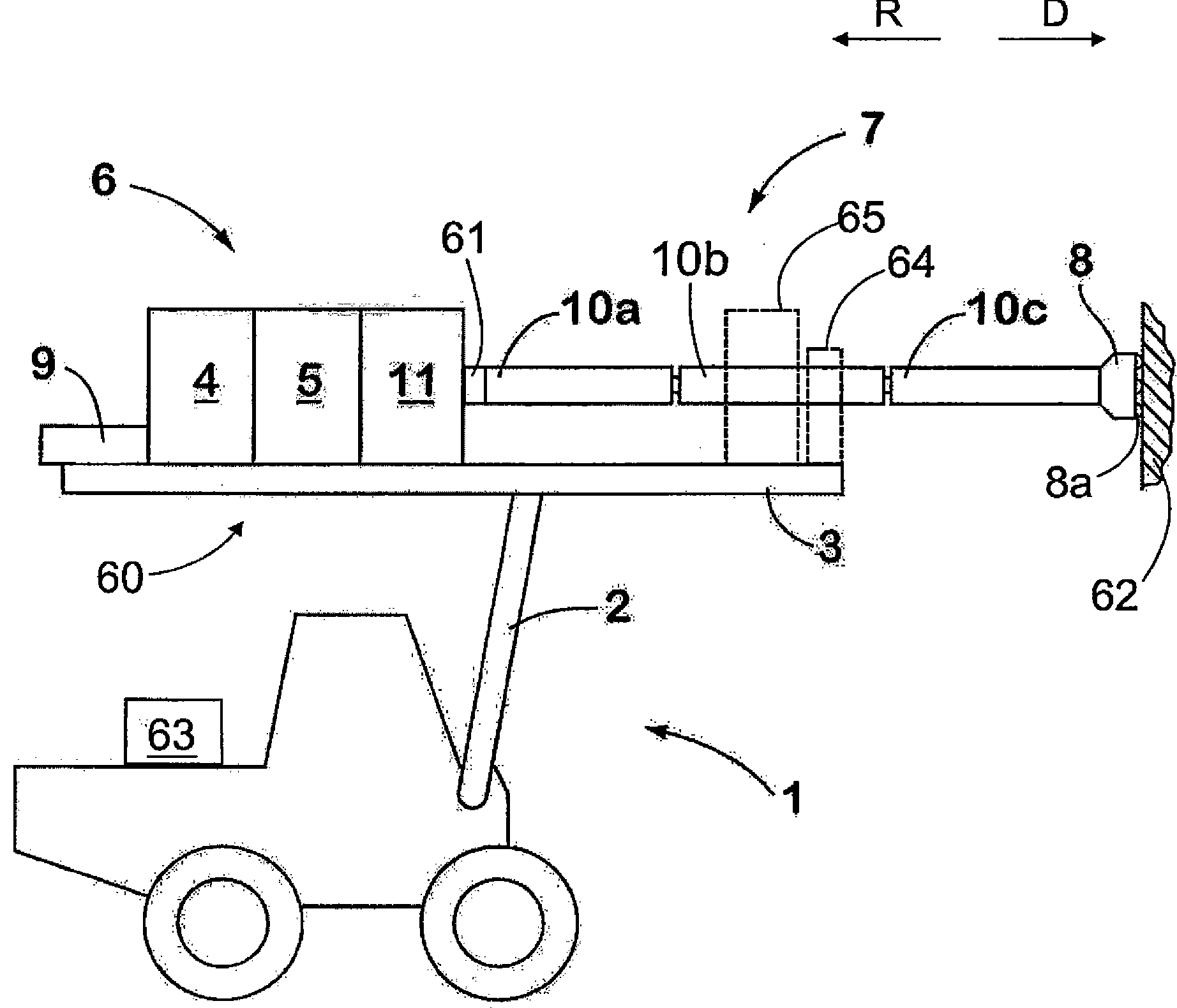

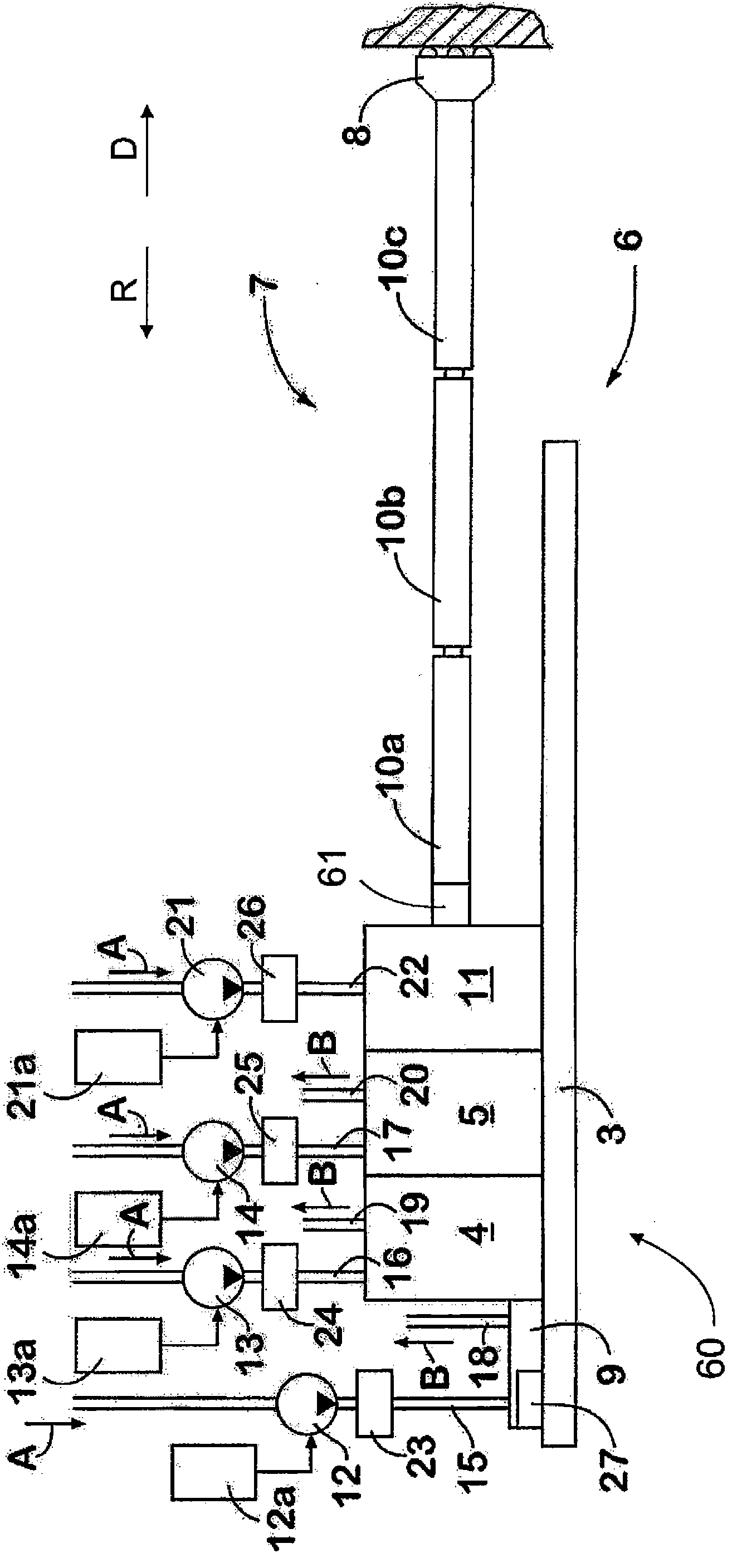

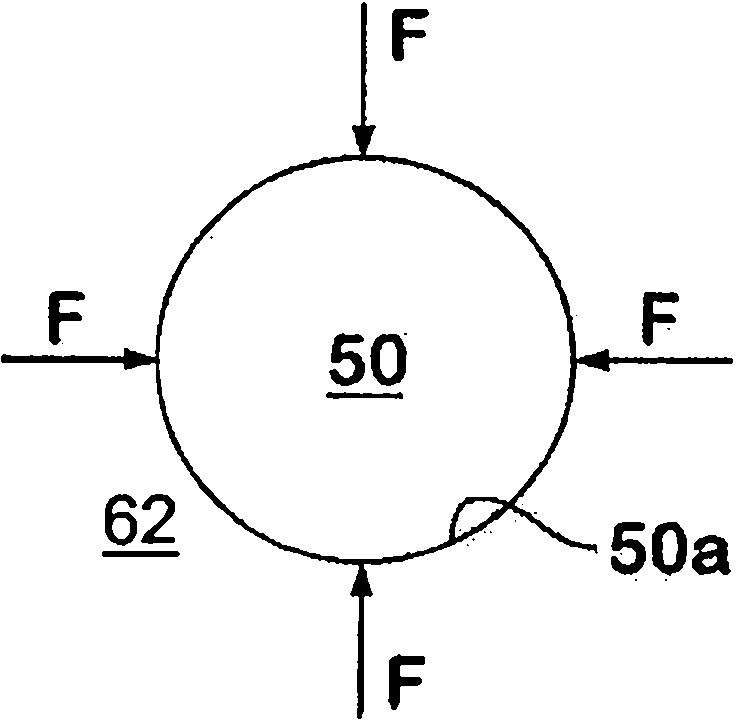

[0034] Figure 1a is a schematic view of a rock drilling apparatus 1 comprising a boom 2 at the end of which there is a rock drilling unit 60 . exist Figure 1b A rock drilling unit 60 , shown in more detail in , comprises a feed beam 3 with a rock drilling machine 6 comprising a percussion device 4 and possibly a rotating device 5 . Typically, the percussion device 4 comprises a percussion piston operated by a pressure medium, and the percussion device 4 strikes the upper end of the tool 7 or a connection arranged between the tool 7 and the percussion device 4 , such as a drill shank 61 . Naturally, it is possible to generate the impact pulse in other ways in the impact device 4 , for example electrically or without a reciprocating impact piston. The proximal end of the tool 7 is connected to the rock drilling machine 6 by a shank 61 and at the distal end of the tool 7 there is a fixed or detachable drill bit 8 for breaking rock. Typically, the drill bit 8 is a drill bit wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com