Coal machine middle groove cantilever welding equipment

A welding equipment, coal machine technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of small increase in production efficiency, irregular shape, large cost investment, etc., to achieve the elimination of weld undercut, welding Beautiful seam formation and improved welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

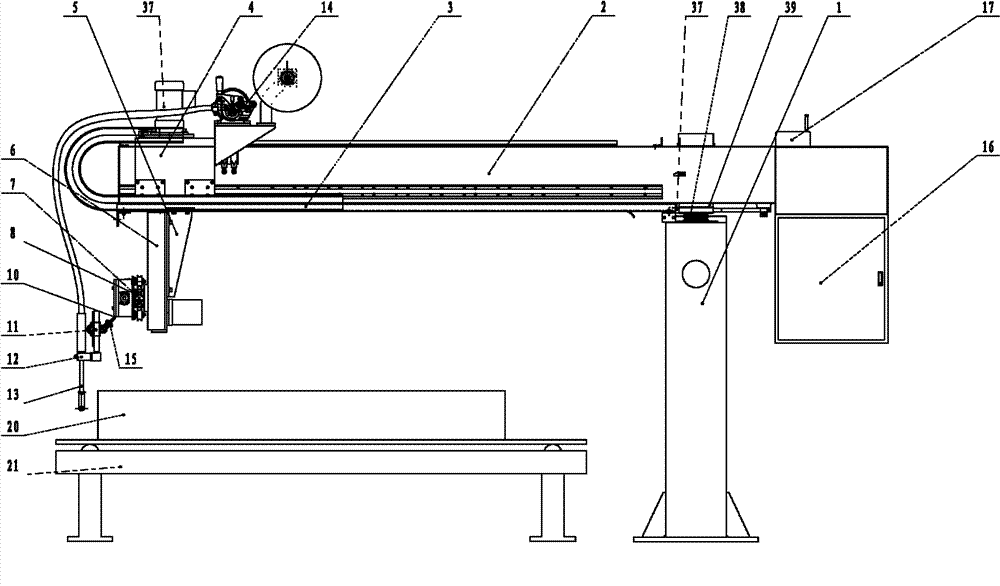

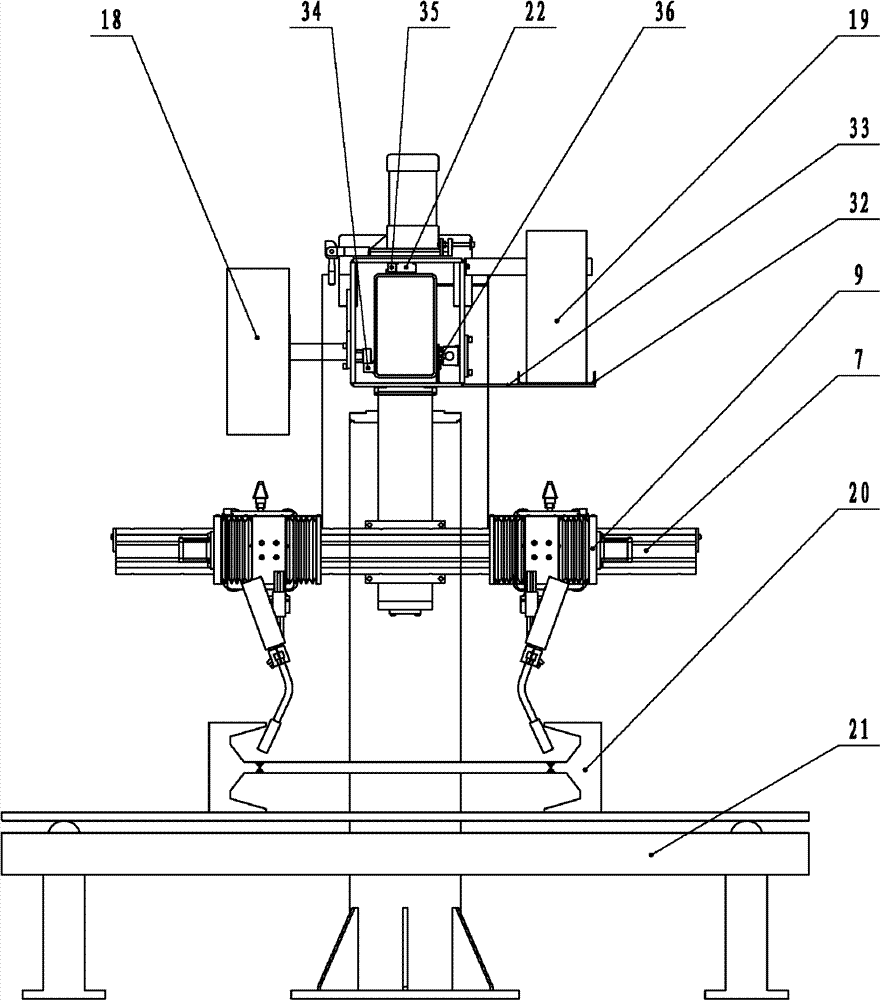

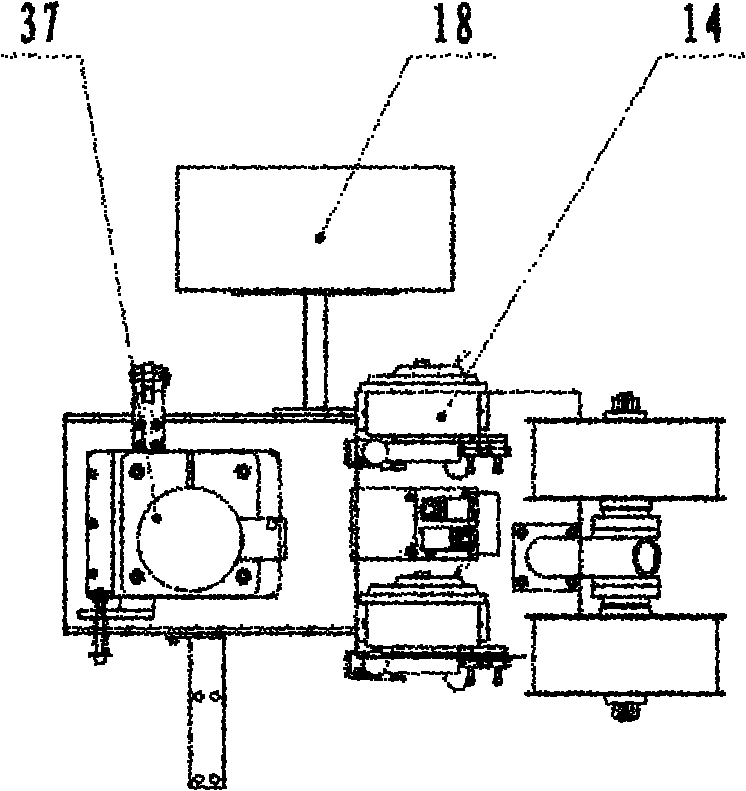

[0036] figure 1 , figure 2 , image 3 , Figure 4 Among them, it includes a vertical beam mechanism 1, a beam mechanism 2, a sliding box mechanism 4, an electric carriage mechanism 6, a welding torch swing device 9, a wire feeding mechanism 14 and an electric control system 16; wherein the beam mechanism 2 is connected to the The vertical beam mechanism 1 is connected and can rotate around the vertical beam mechanism 1 within the range of ±90°, and the angle positioning is carried out by the locking mechanism; an electric control system 16 is provided at the end of the beam mechanism 2, and a slide for relative movement is provided at the other end. The box mechanism 4 and the wire feeding mechanism 14 are equipped with an electric carriage mechanism 6 at the bottom of the sliding box mechanism 4, and a welding gun swing device 9 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com