High-strength unequal helical angle end mill

A helix angle, high-strength technology, applied in the direction of milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of different chip thickness and deformation, wear and damage, and large cutting load, so as to improve cutting efficiency and service life. Strong wear ability and good chip guide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

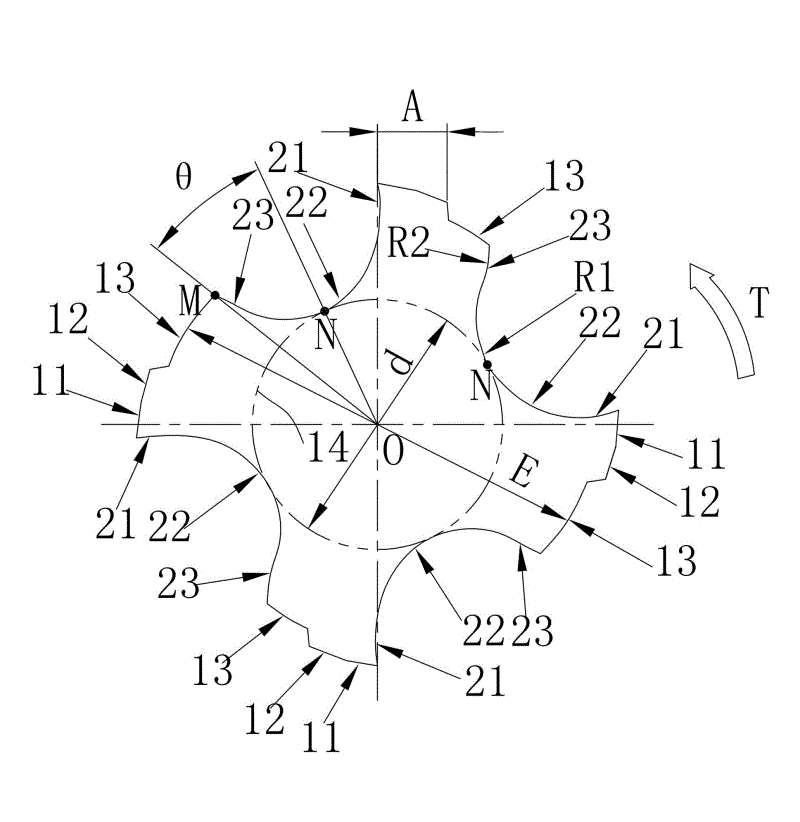

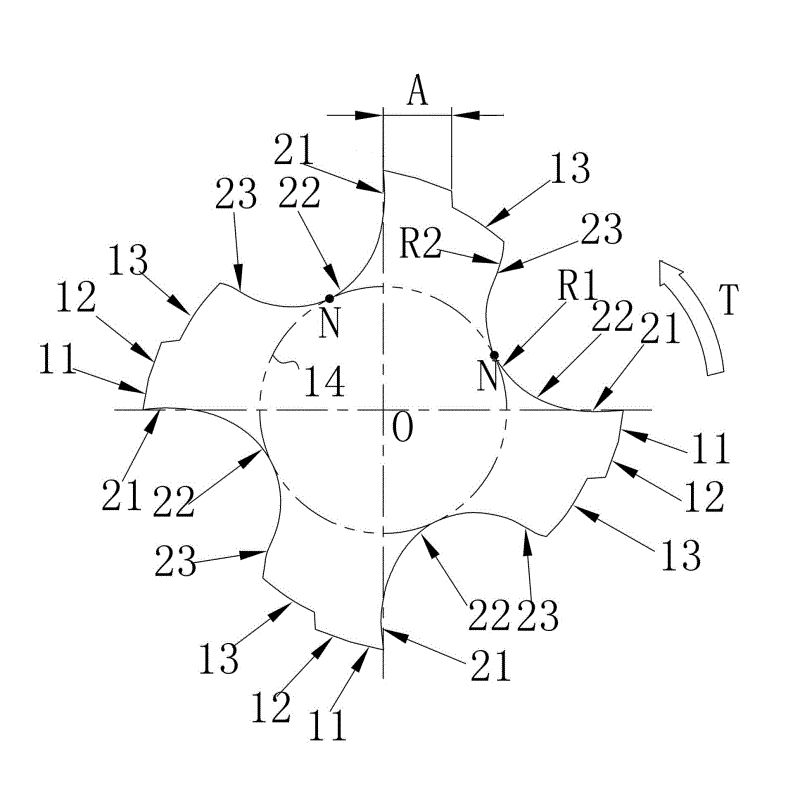

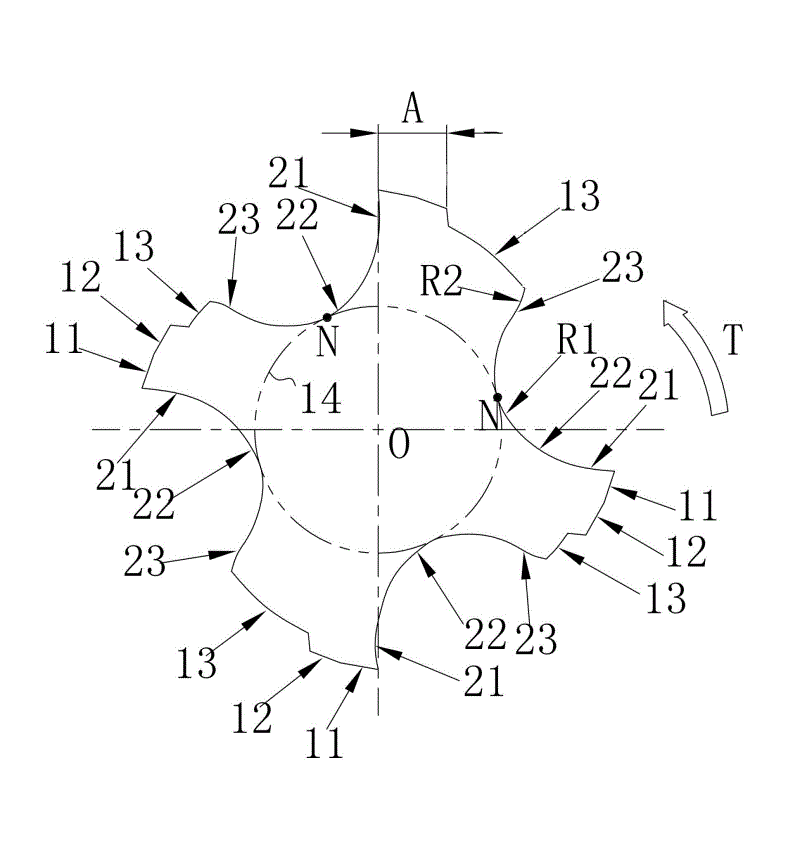

[0021] Figure 1 to Figure 4 It shows an embodiment of a high-strength unequal helix angle end mill of the present invention. The end mill includes a cutting part 1 and a shank part 2. Chip flutes 4, each flute 4 faces the direction of cutting rotation ( figure 2 The surface in the direction indicated by the middle arrow T) is the rake face 21, the rake face 21 intersects with the outer peripheral surface of the cutting part 1 to form a peripheral cutting edge 3, and the helix angle of at least one peripheral cutting edge 3 is different from that of other peripheral cutting edges 3, Among the outer peripheral surfaces of the cutting portion 1, the surface that is in contact with the peripheral edge 3 is the first flank face 11, and the face that is in contact with the first flank face 11 is the second flank face 12, and the total length of the cutting portion 1 is Ap, The first flank surface 11 extends from the bottom end of the cutting portion 1 to the shank portion 2 as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com