Technology for making small-diameter logs into laminated wood

A technology of glulam and logs, which is applied in the direction of wood processing equipment and manufacturing tools, can solve the problems of small-diameter log waste, low production efficiency, adhesive waste, etc., and achieve short cold pressing cycle, high production efficiency, and compact assembly way simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below by embodiment the present invention will be further described.

[0019] 1. Fixed length: Small-diameter logs of different lengths are longitudinally cut or length-fixed, and 2m-long small-diameter log segments are prepared, and then log segments of different diameter classes are sorted, such as figure 2 shown.

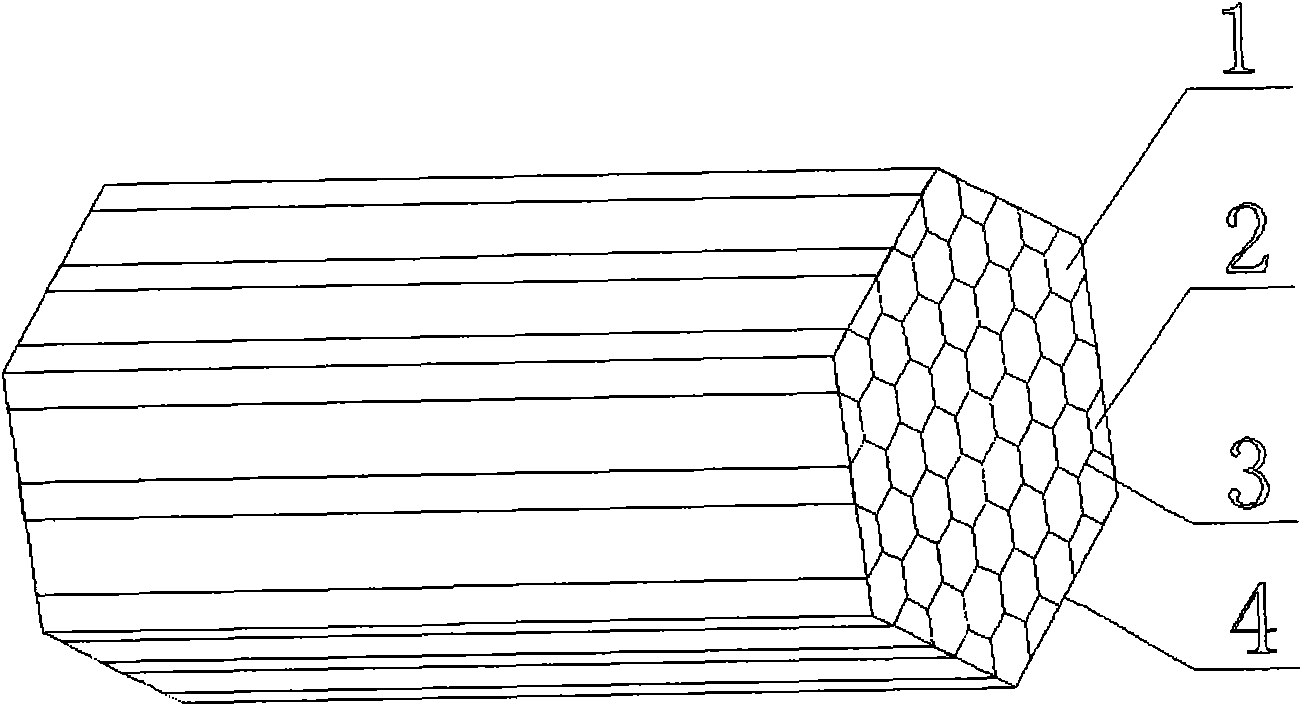

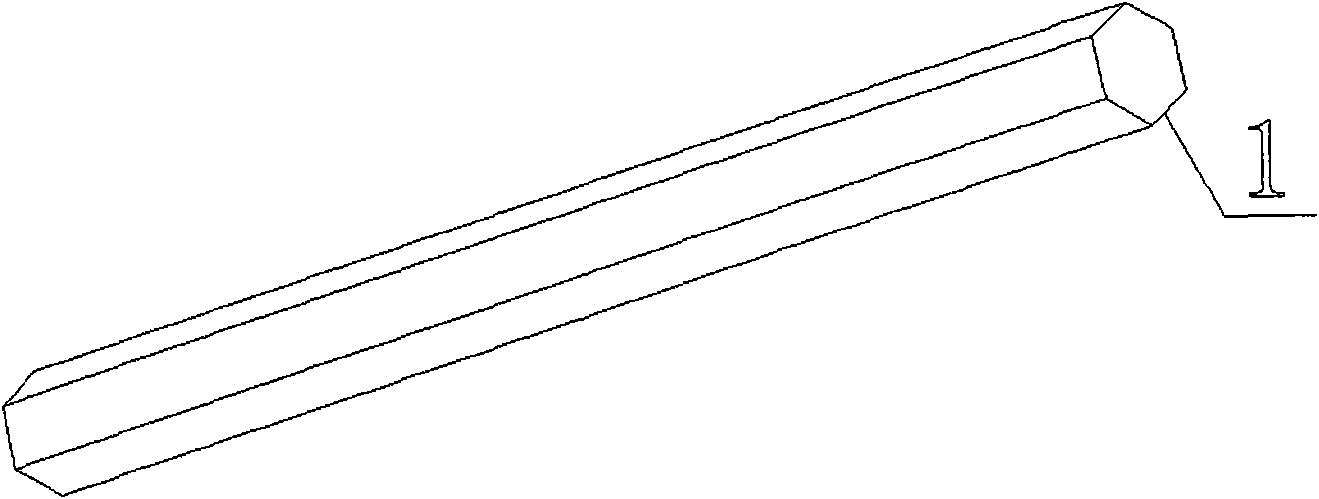

[0020] 2 Square material processing: Through the self-adaptive shaving and lumber combining machine, log segments of different diameters and lengths are processed into different small-sized regular hexagonal prisms (1) and semi-regular hexagonal prisms (2), such as image 3 and Figure 4 shown.

[0021] 3 Glue coating: through the automatic glue coating device, the small-sized regular hexagonal prism (1) or semi-regular hexagonal prism (2) is coated with EPI cold pressure glue on multiple or three sides, such as figure 1 (3) shows the adhesive layer.

[0022] 4 groups of blanks: according to the needs, the same small-sized regular hexagonal prism (1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com