Unpowered powder pumping and continuous dispersive mixing method and device

A mixing device and dispersion technology, applied in the direction of mixing methods, mixers, fluid mixers, etc., can solve the problems of affecting the solute fusion effect of disinfectants, increasing the investment cost of manufacturers, and blockage of water pump impellers, etc., to achieve low power consumption , Improve the spraying accuracy and distance, and the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing and specific implementation;

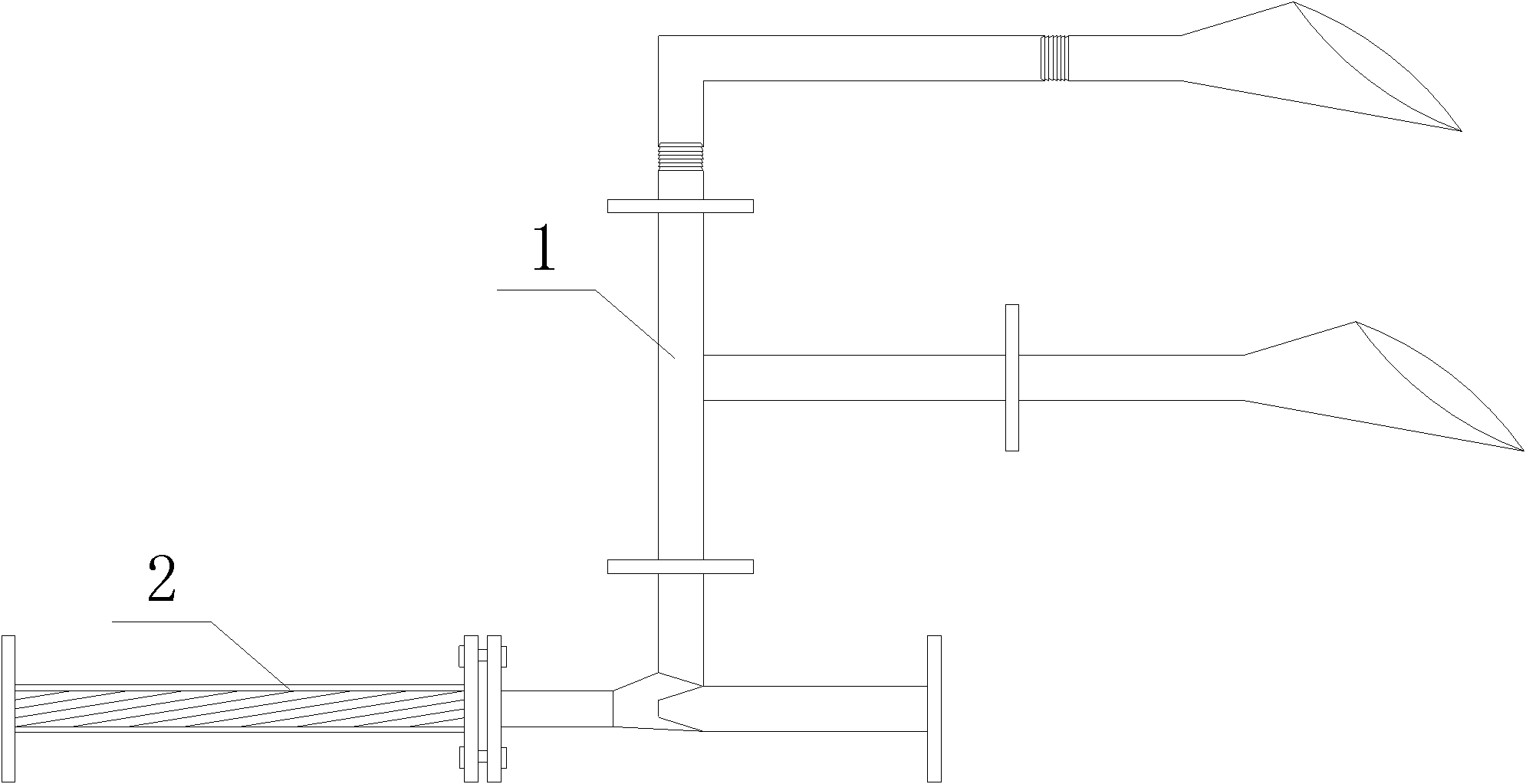

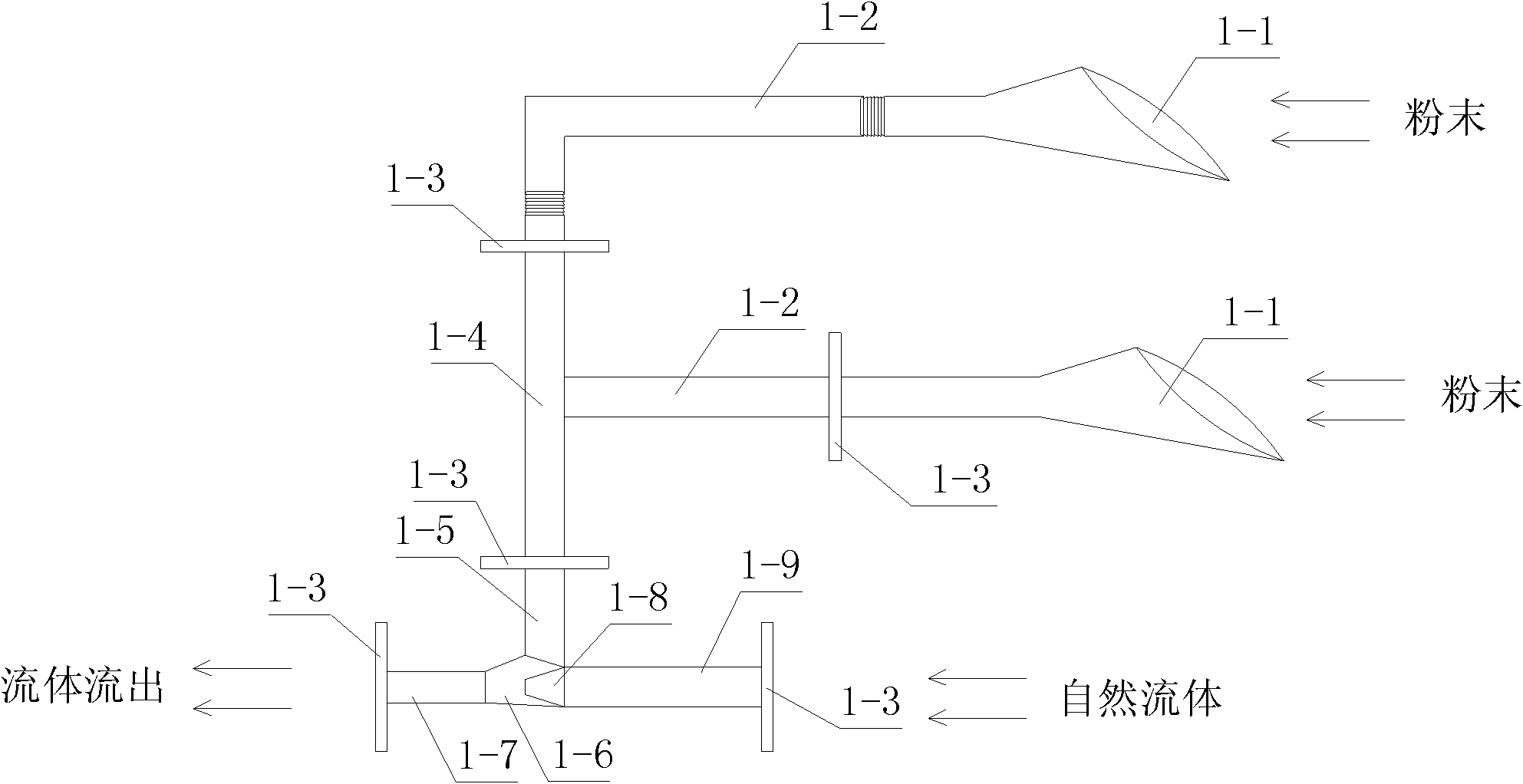

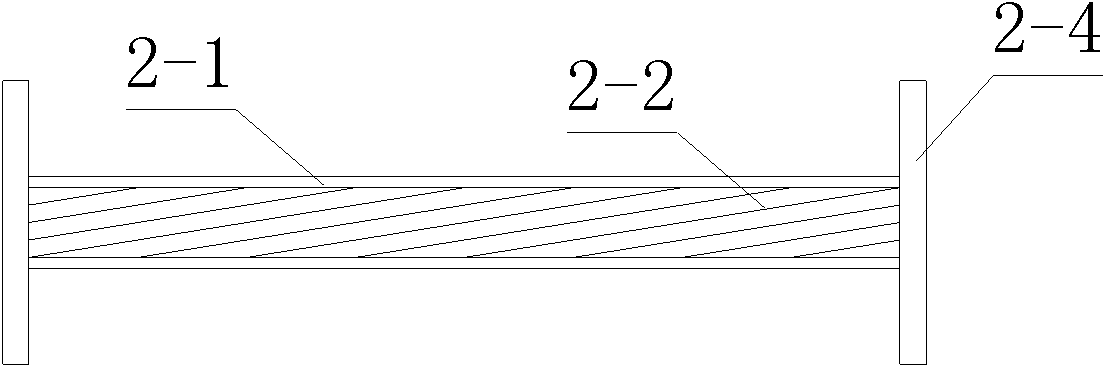

[0019] see Figure 1 to Figure 4 , a non-powered powder suction, continuous dispersion mixing device, consisting of a shaftless spiral dispersion mixing device 2 and a powder suction device 1, the shaftless spiral dispersion mixing device 2 includes a pipe body 2-1, and also includes Several helical bodies 2-2, the helical body 2-2 is a helical structure, there are several helical tracks 2-3 on the inner wall of the tube body 2-1, the helical bodies 2-2 are embedded on the helical track 2-3, and on the tube body 2-1 The two ends of the body 2-1 are provided with flanges 2-4, and the spiral rails 2-3 are equidistantly arranged on the cross section of the tube body 2-1; the powder suction device 1 includes a powder suction tube 1-2, The powder delivery pipe 1-4 is also provided with a powder suction funnel 1-1 on the other end of the powder suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com