Ion beam etching machine and etching method thereof

An ion beam etching machine and ion source technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of expensive ion beam etching machine equipment, high cost, and difficult manufacturing, and achieve uniformity and stability. Good, reduce equipment cost, improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

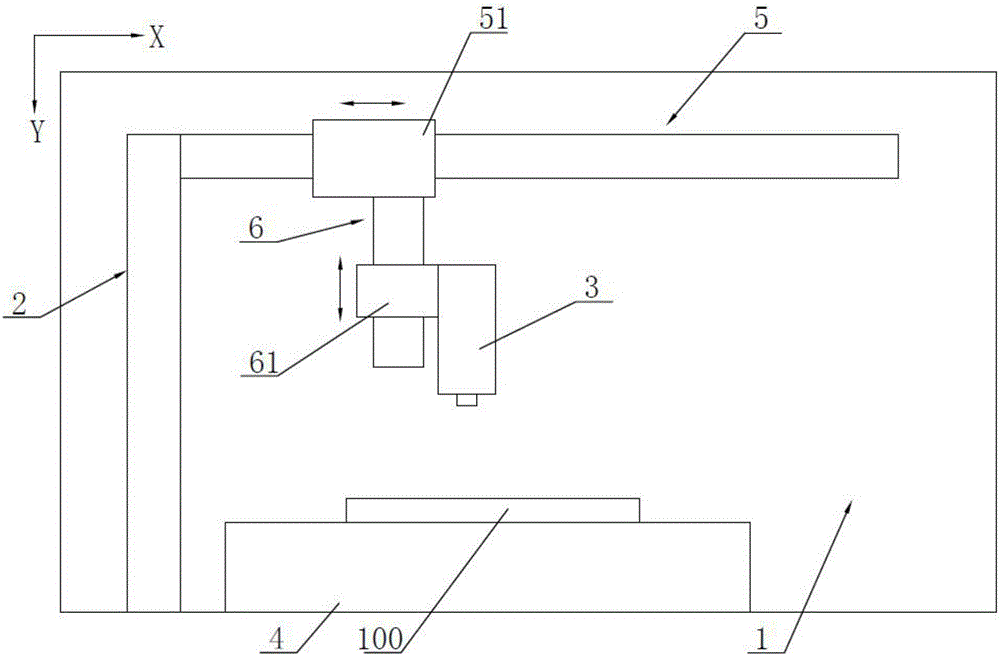

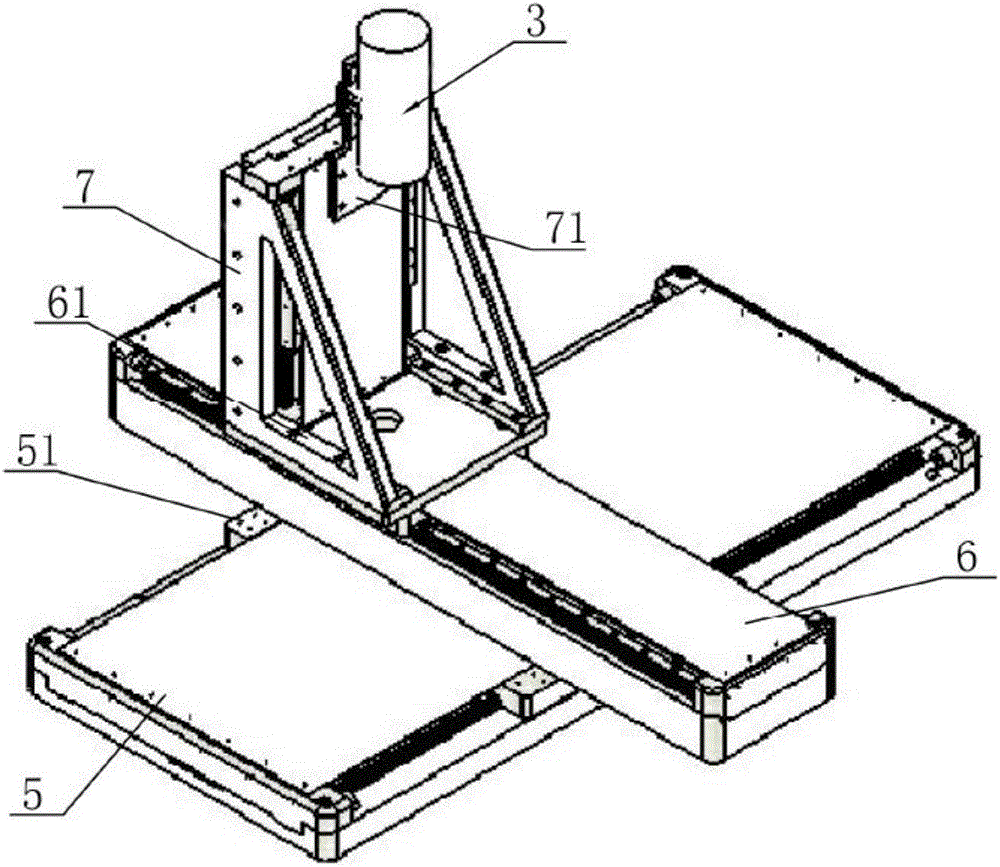

[0036] Embodiment 2: On the basis of Embodiment 1, the multi-axis motion system 2 can also be expanded. This embodiment uses a three-axis motion system. Such as figure 2 Said, the three-axis motion system includes the X-axis linear motion module 5, the Y-axis linear motion module 6 and the Z-axis linear motion module 7 arranged according to the space Cartesian coordinate system, the X-axis linear motion module 5, the Y X-axis linear motion module 6 and Z-axis linear motion module 7 are perpendicular to each other. The Y-axis linear motion module 6 is fixedly connected to the X-axis linear motion element 51 of the X-axis linear motion module 5. The Z-axis The linear motion module 7 is fixedly connected to the Y-axis linear motion element 61 of the Y-axis linear motion module 6, and the ion source 3 is fixedly installed on the Z-axis linear motion element 71 of the Z-axis linear motion module 7. Driven by the three-axis motion system, the source 3 can move along the X-axis, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com