Fluid dynamic bearing motor for use with a range of rotational speed rated disc drive memory device products

A hydrodynamic bearing and fluid technology, applied in the direction of bearings, mechanical equipment, shafts and bearings, etc., can solve the problems of high manufacturing cost, high production cost, low sales volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

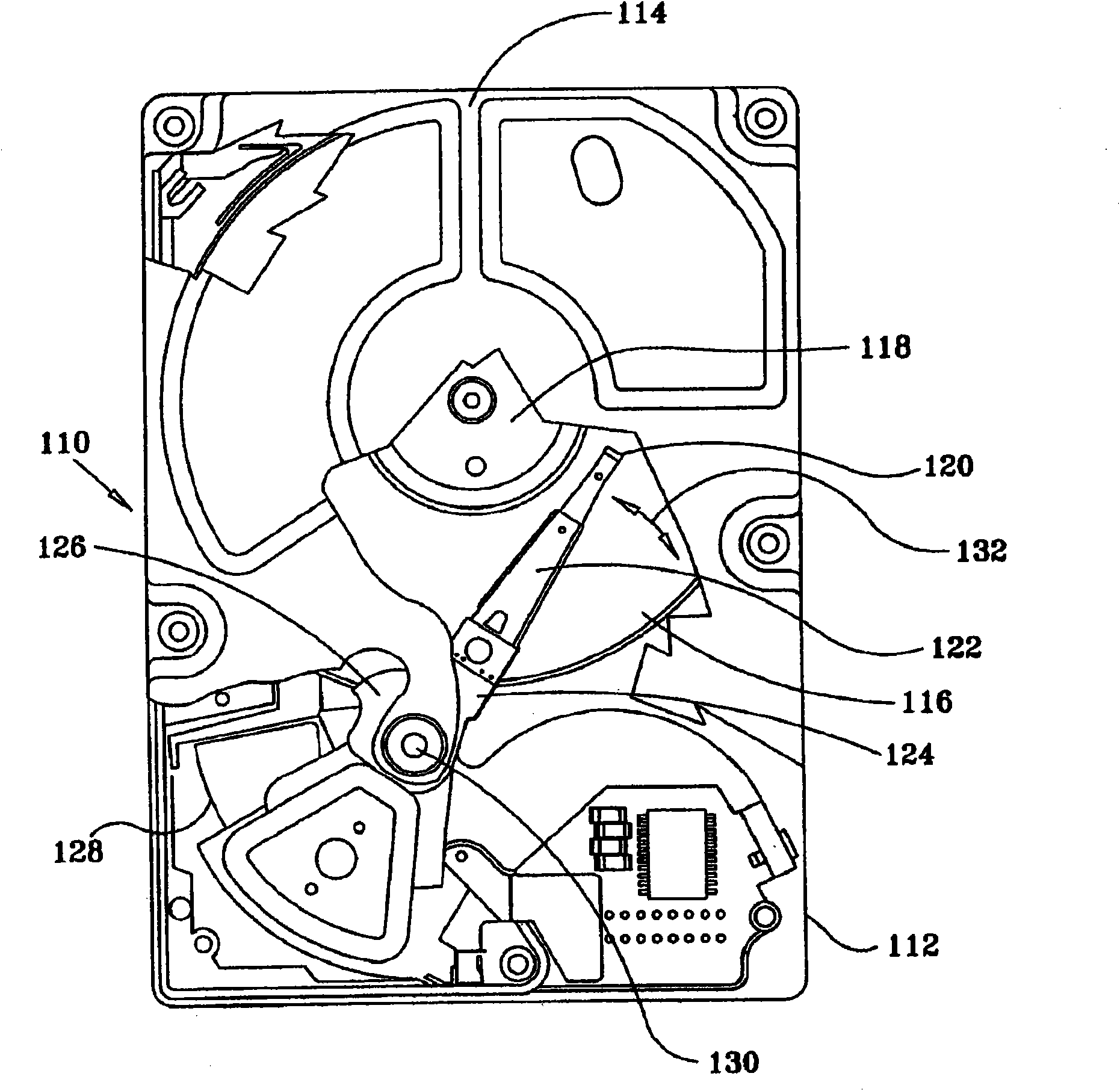

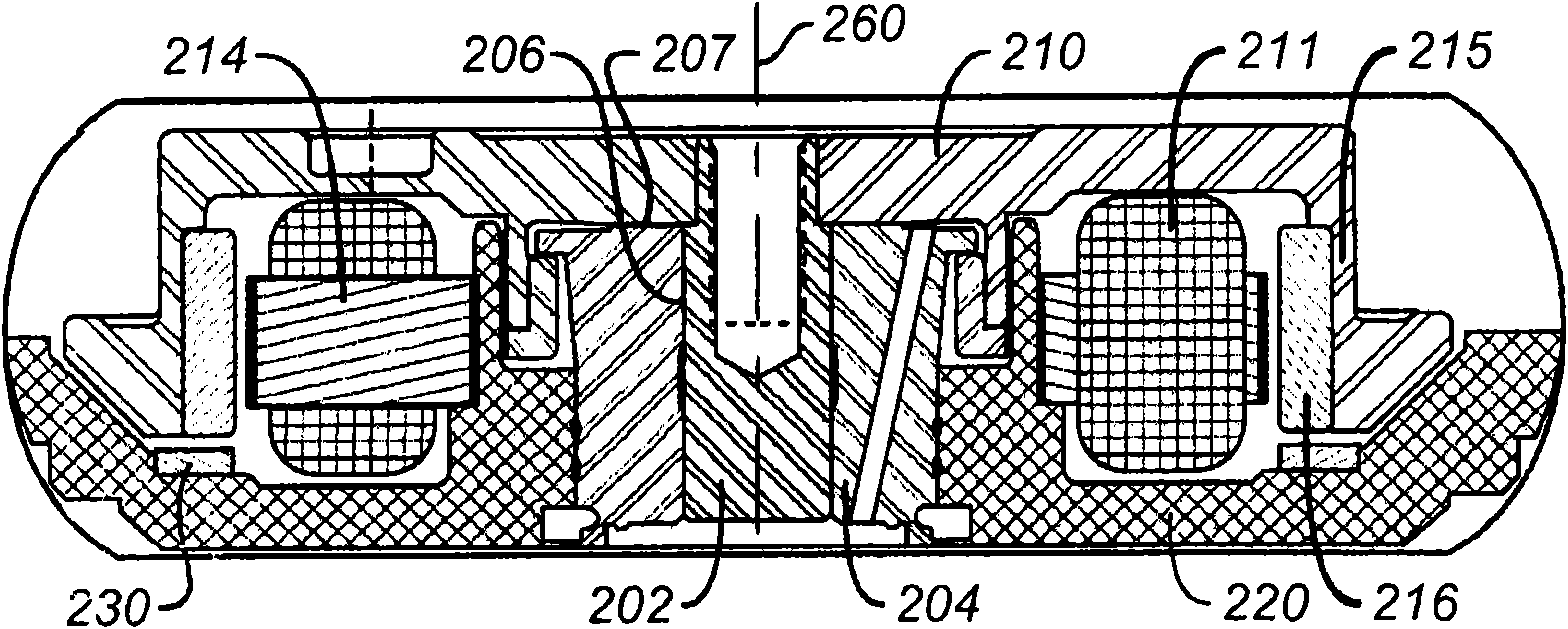

[0076] Exemplary embodiments will be described in conjunction with specific structures. Those skilled in the art will appreciate that various changes and modifications can be made without departing from the scope of the appended claims. Furthermore, well-known elements, devices, components, methods, process steps, etc. have not been described in detail so as not to obscure the present invention.

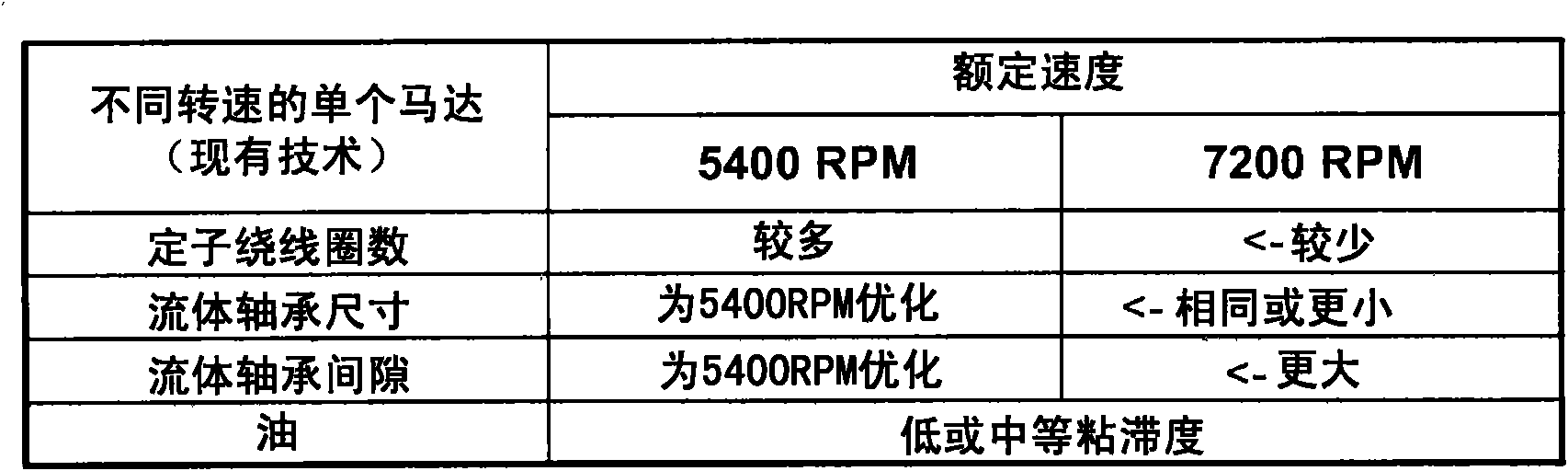

[0077] In order to reduce the production cost of disk drive motors for high-end disk drive products that typically do not sell well, it is desirable to use a single motor design for a range of different rated speed disk drive storage device products (i.e., 5400 RPM) operating at different rated speeds. with 7200RPM speed product). As a result, overall manufacturing volumes are increased and the cost increases associated with dedicated lines for high-end 7200RPM products can be avoided. However, motors designed to run at 7200 RPM typically include a motor torque constant (Kt) lower ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap