Assembled hot air stove

A hot blast stove, assembled technology, applied in the directions of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of scrapped furnace body, insufficient utilization of combustion heat, waste of resources, etc., to save resources and solve Energy crisis and environmental pollution, the effect of sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

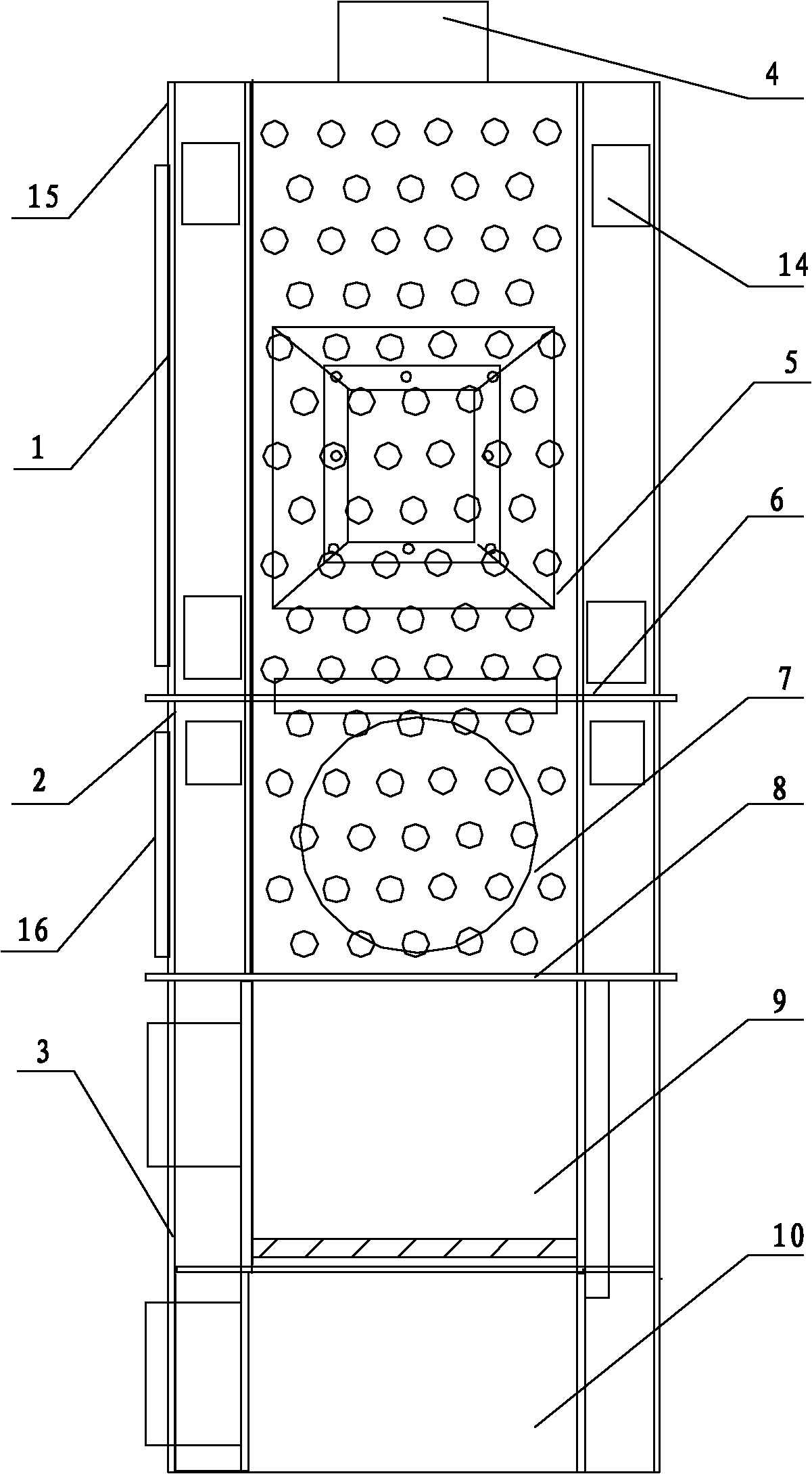

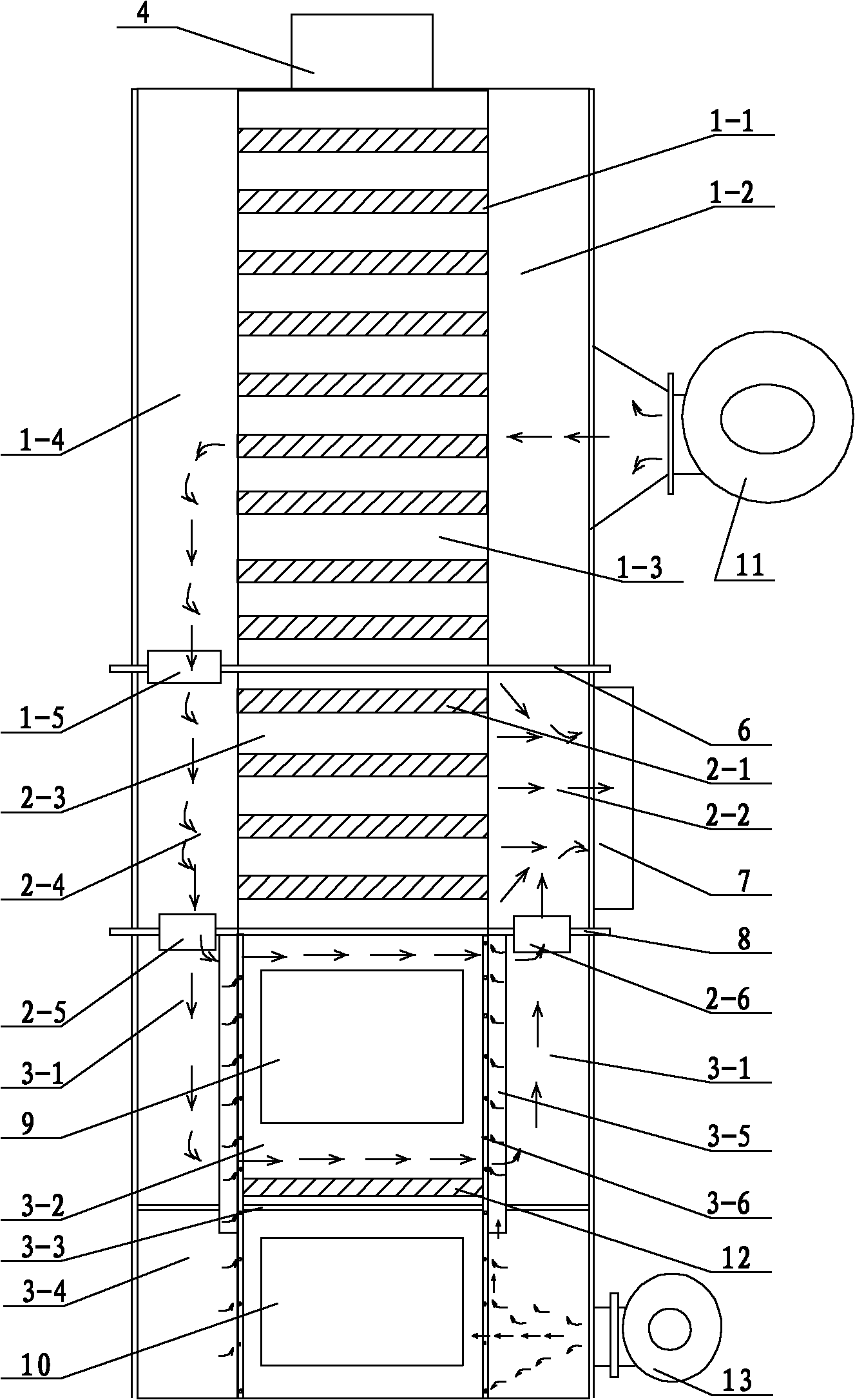

[0026] See figure 1 , figure 2 The fuel of the present invention can use industrial waste, white waste, dry food waste, discarded crops, leftover wood, various coals, etc., and can achieve full combustion, achieving smokeless and dustless effects. It can be widely used in shell-shaped boilers, environmental protection boilers, heaters and drying furnaces, etc., and can also be used as rural household stoves, outdoor heating or field heating.

[0027] The number of air holes in the furnace body 3 of the heat exchange part and the wall of the secondary heating furnace body 2 that lead into the furnace is related to the size of the furnace. The larger the furnace diameter, the more the number of air holes, and vice versa.

[0028] The primary heating furnace body 1 and the secondary heating furnace body 2 of the heat exchange part are sequentially located above the combustion part furnace body 3, the bottom of which is in communication with the combustion chamber of the combustion fur...

Embodiment 2

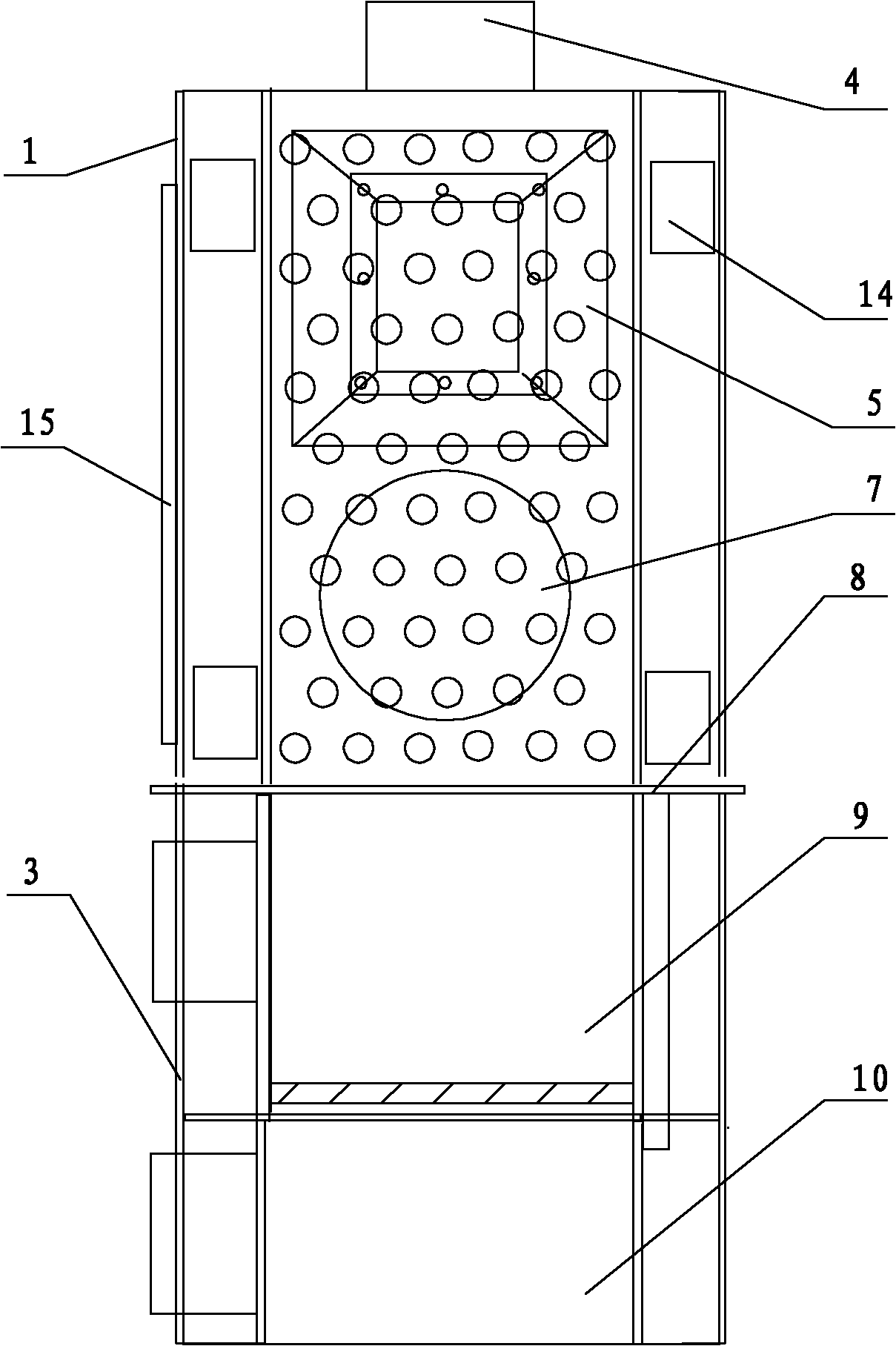

[0030] See image 3 , Figure 4 , The assembled hot blast stove is composed of a combustion part and a primary heating furnace body 1 of the heat exchange part, and the furnace of the combustion part is used to achieve secondary heating. Others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com