Interface of non-polyvinyl chloride (PVC) infusion bag

An infusion bag and interface technology, applied in the field of hard mouth interface, can solve the problems of low welding efficiency, increase pre-assembly process, cracking, etc., and achieve the effect of improving production efficiency, improving production process and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

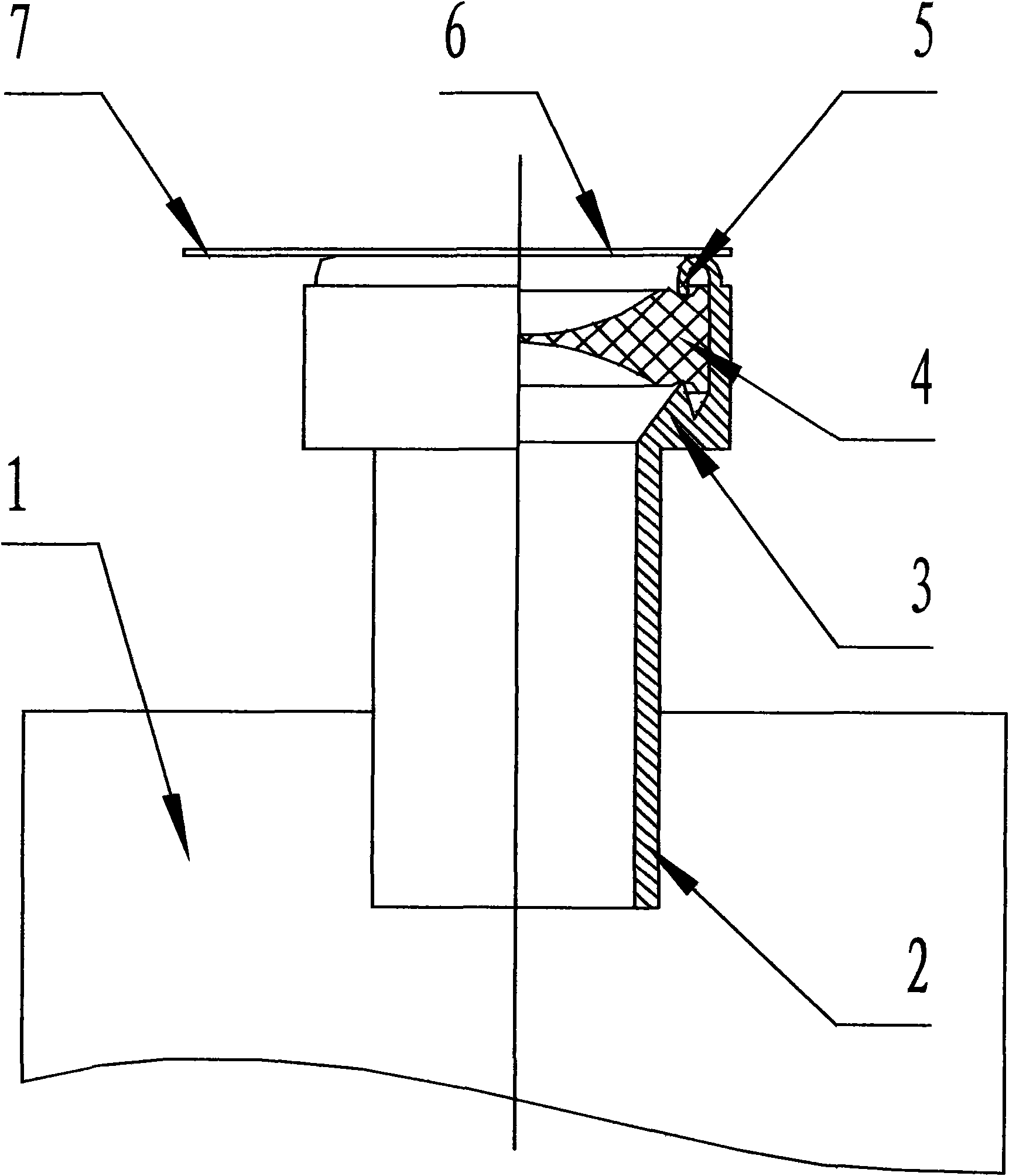

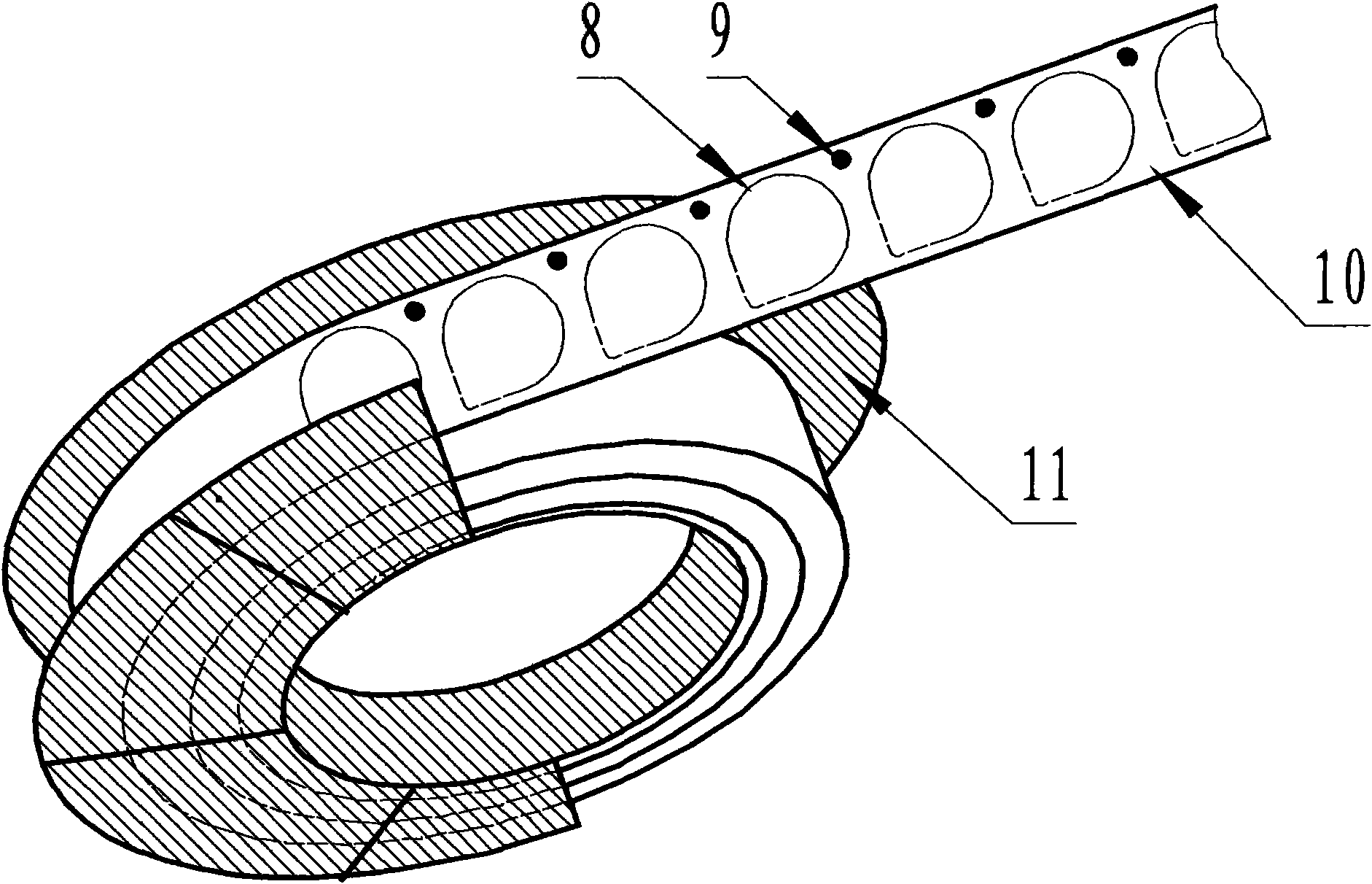

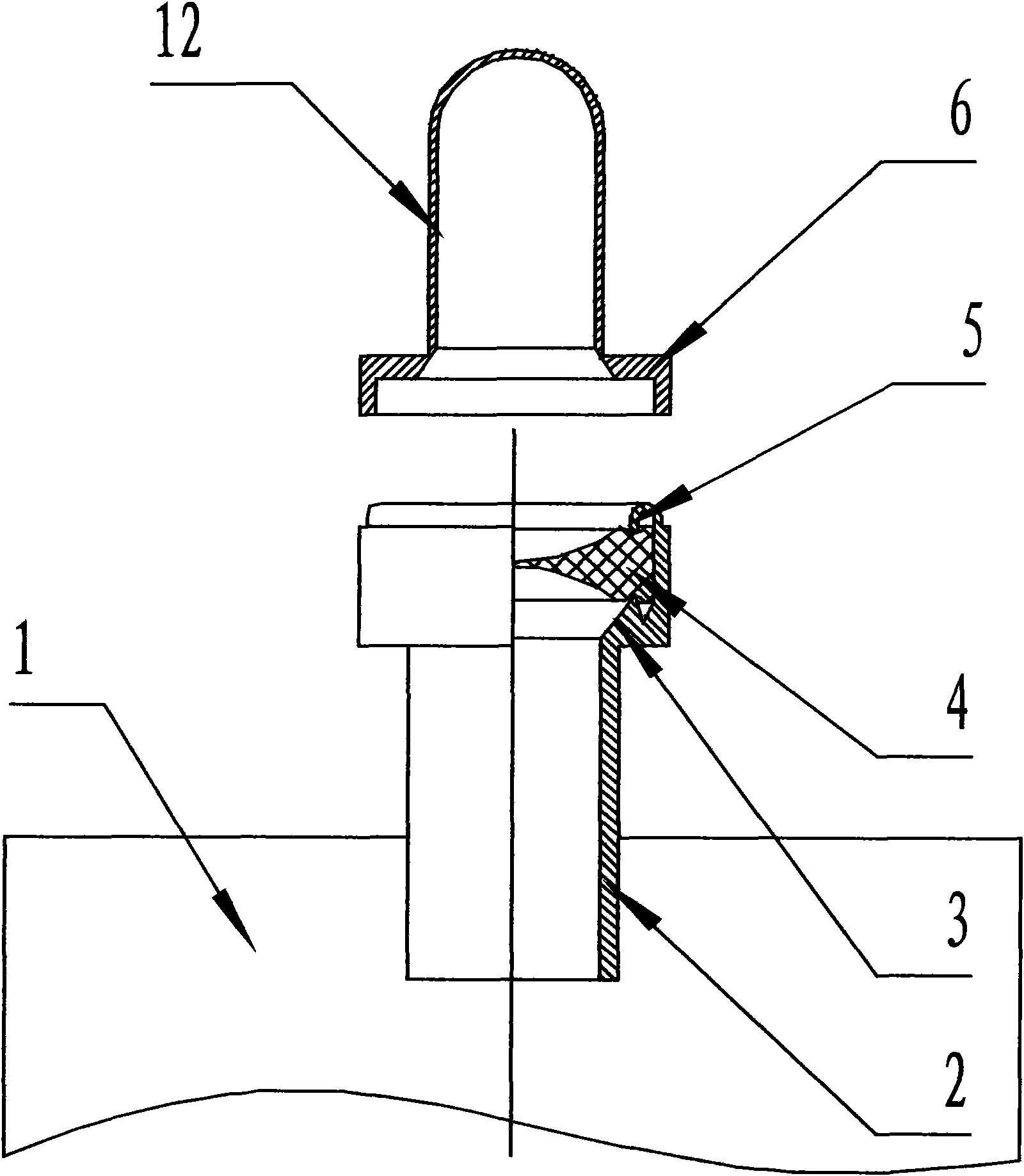

[0014] exist figure 1 In the process, heat the lower end of the connecting tube (2) and the infusion bag (1) together first, and then fill the rubber plug (4) into the mouth of the connecting tube after filling. The upper port of the connecting tube is higher than the upper end surface of the rubber plug Bend back to the inside under the action, the upper port (5) of the connecting pipe after the bending is downward and the inner diameter is smaller than the outer diameter of the rubber plug, so as to block the rubber plug; The axial distance between the end surface support steps (3) is smaller than the thickness of the rubber plug, so that the upper port of the connecting pipe after being bent back will be embedded in the upper surface of the rubber plug and the outer diameter of the rubber plug will be extruded to increase, thus playing a double sealing role. exist figure 2 There are multiple groups of closed continuous rows of holes (8) evenly distributed on the strip pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com