Micro-channel tubular heat exchanger for dehumidification and dehumidifier

A micro-channel and heat exchanger technology, applied in refrigerators, tubular elements, heat exchange equipment, etc., can solve the problems of high manufacturing cost of dehumidifiers, unfavorable for condensed water removal, etc., to improve the removal effect, improve performance, reduce The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

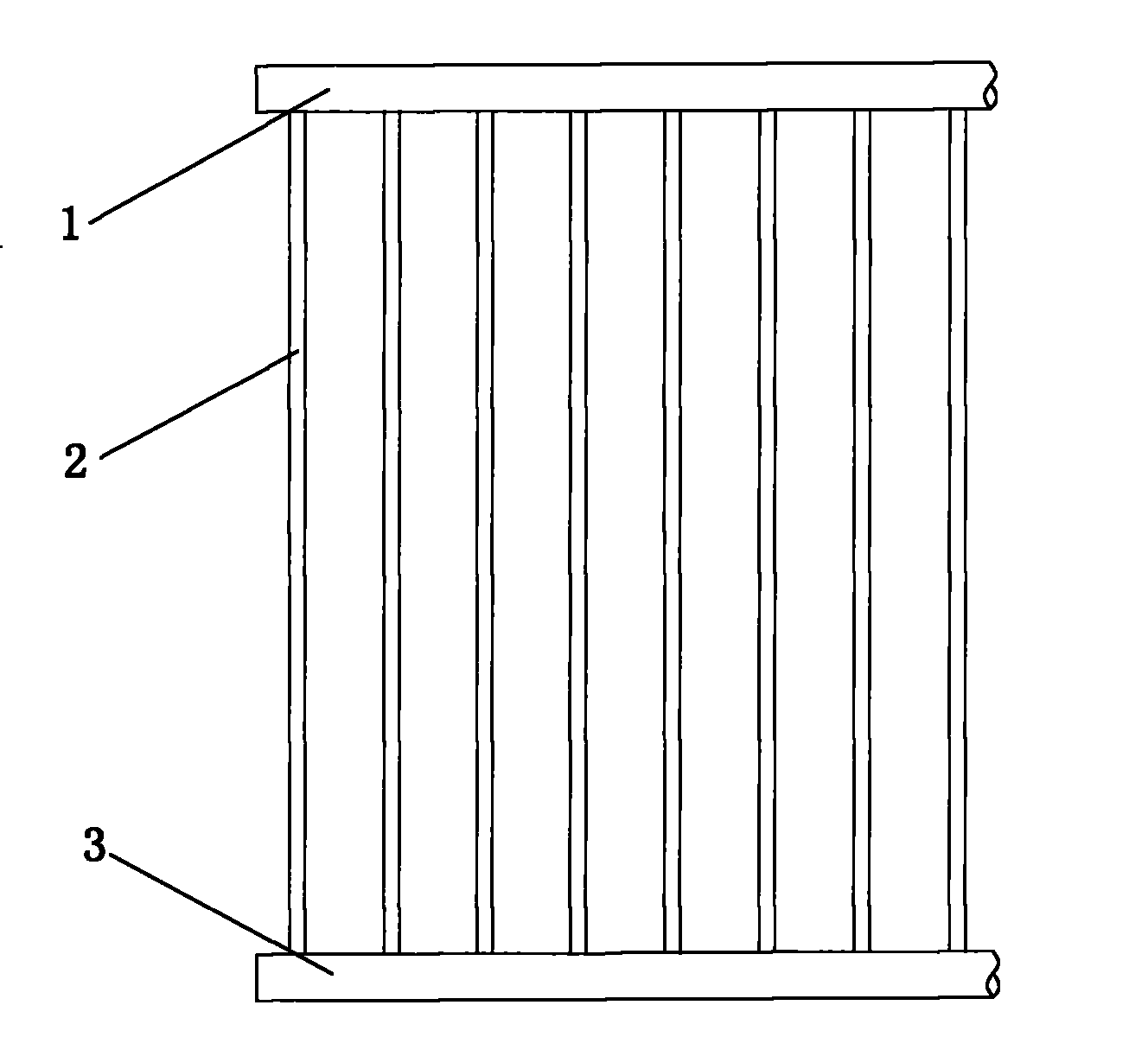

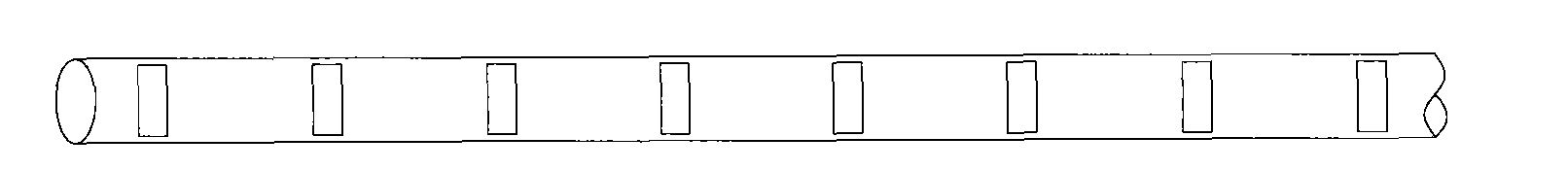

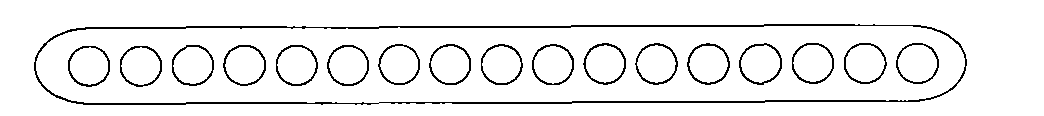

[0030] Such as figure 1 As shown, the microchannel tube heat exchanger for dehumidification in this embodiment consists of an upper header 1, a lower header 3, and several flat tubes 2 arranged between the upper and lower headers, which are parallel to each other and perpendicular to the upper and lower headers. The structural forms of the upper header 1 and the lower header 3 are as follows figure 2 As shown, the figure only shows the case where the header is a round tube. In fact, the header can also be in other forms, such as square tubes, elliptical tubes, and the like. The cross-sectional structural form of the flat tube 3 is as image 3 As shown, the figure only shows the situation that the cross-sectional flow channel is circular, in fact, the cross-sectional flow channel can also be in other forms, such as square, triangular, etc.

[0031] When the microchannel tube heat exchanger for dehumidification is used in a dehumidifier heat exchanger, the refrigerant gas-liq...

Embodiment 2

[0033] Such as Figure 4 As shown, the microchannel tube heat exchanger for dehumidification in this embodiment is based on Embodiment 1, and one or more liquid drainage spacers 4 are arranged obliquely on the flat tube 2, and the liquid drainage spacers 4 can be such as Distance or non-equidistant distribution, this embodiment is equidistant distribution. For the relative position of the drain spacer 4 and the flat tube 2 see Figure 5 , Figure 5 Among them, the liquid drainage spacer 4 forms a certain angle θ with the horizontal position (0<θ<90°), and the liquid drainage spacer 4 is always located on the leeward side of the microchannel tube heat exchanger. In this way, the condensed water condensed on the flat tube 2 flows down along the flat tube 2 under the action of gravity, and when the condensed water reaches the drain spacer 4, the condensed water will flow down The liquid spacer 4 flows down, that is, the drainage spacer 4 can reduce the amount of condensed wate...

Embodiment 3

[0035] Such as Figure 6 As shown, the microchannel tube heat exchanger for dehumidification, its upper header includes a gas collector assembly 5 and a liquid pipe assembly 6; the microchannel tube heat exchanger for dehumidification also includes a lower header 3 and several flat tubes 2 composition; the air collecting pipe assembly 5 such as Figure 7 As shown, the air collecting pipe assembly 5 in the figure is composed of an air collecting pipe 51 and an air collecting branch pipe 52. The air collecting pipe assembly 5 is located on the top of the flat pipe 2; Wherein the cross-sectional view of the gas-collecting branch pipe 52 and the connection part of the flat pipe 2 is as follows: Figure 9 As shown, the top of the flat tube 2 communicates with the gas collecting branch pipe 52 . Figure 7 What is shown in is only one form of air collecting pipe assembly, in fact, it can also be in other forms. The dispenser assembly 6 see Figure 8 As shown, what is shown in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com