Optical pickup device, optical disc device and focus adjusting method

A technology for an optical pickup device and an optical disc device, which is applied in the directions of recording/reproducing by optical methods, optical discs, and disc-shaped record carriers, etc., can solve the problems of an increase in the proportion of stray light, an increase in the number of parts and costs, and a large-scale optical system, etc. Achieving the effect of suppressing the DC component and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0057]

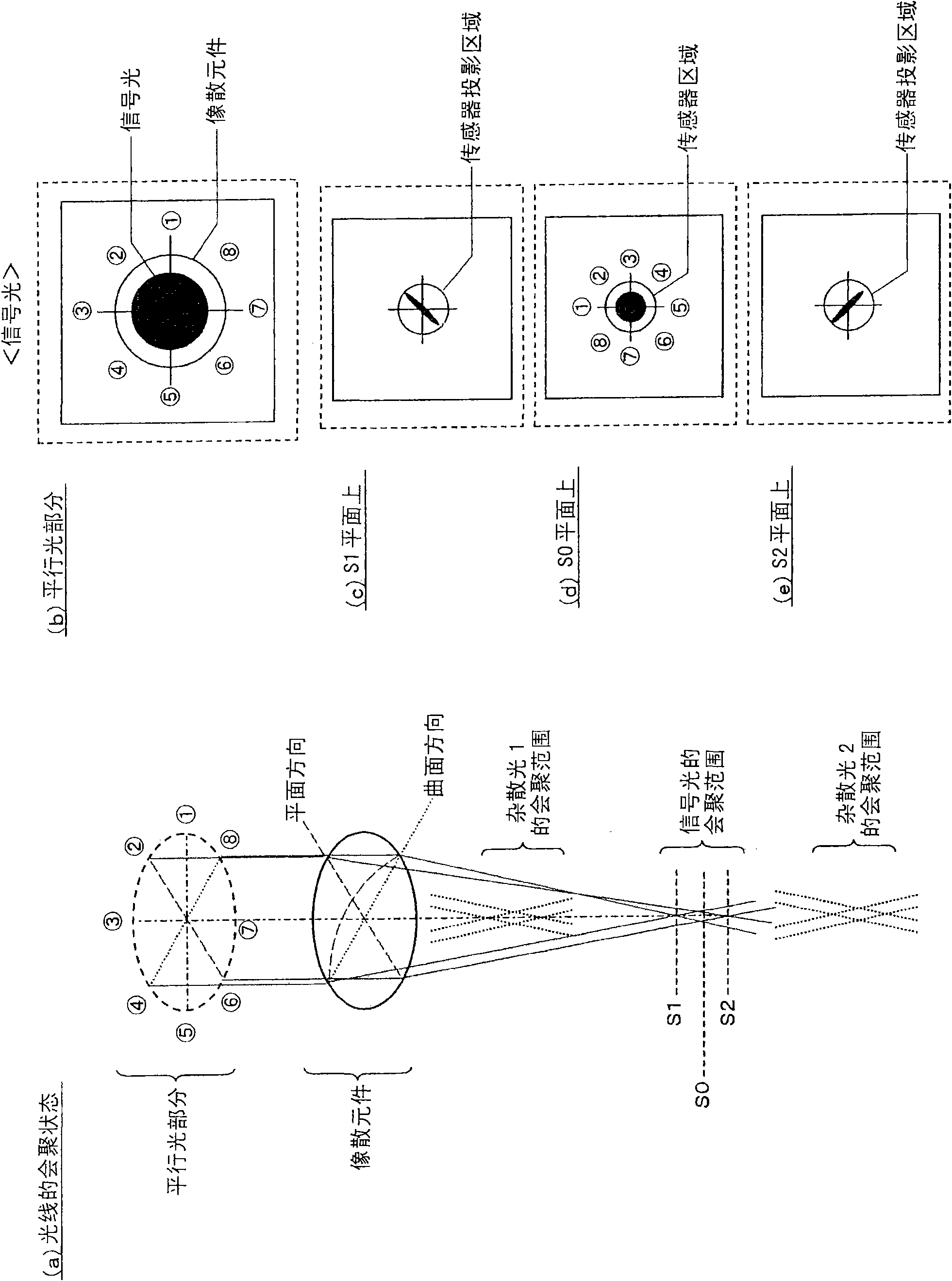

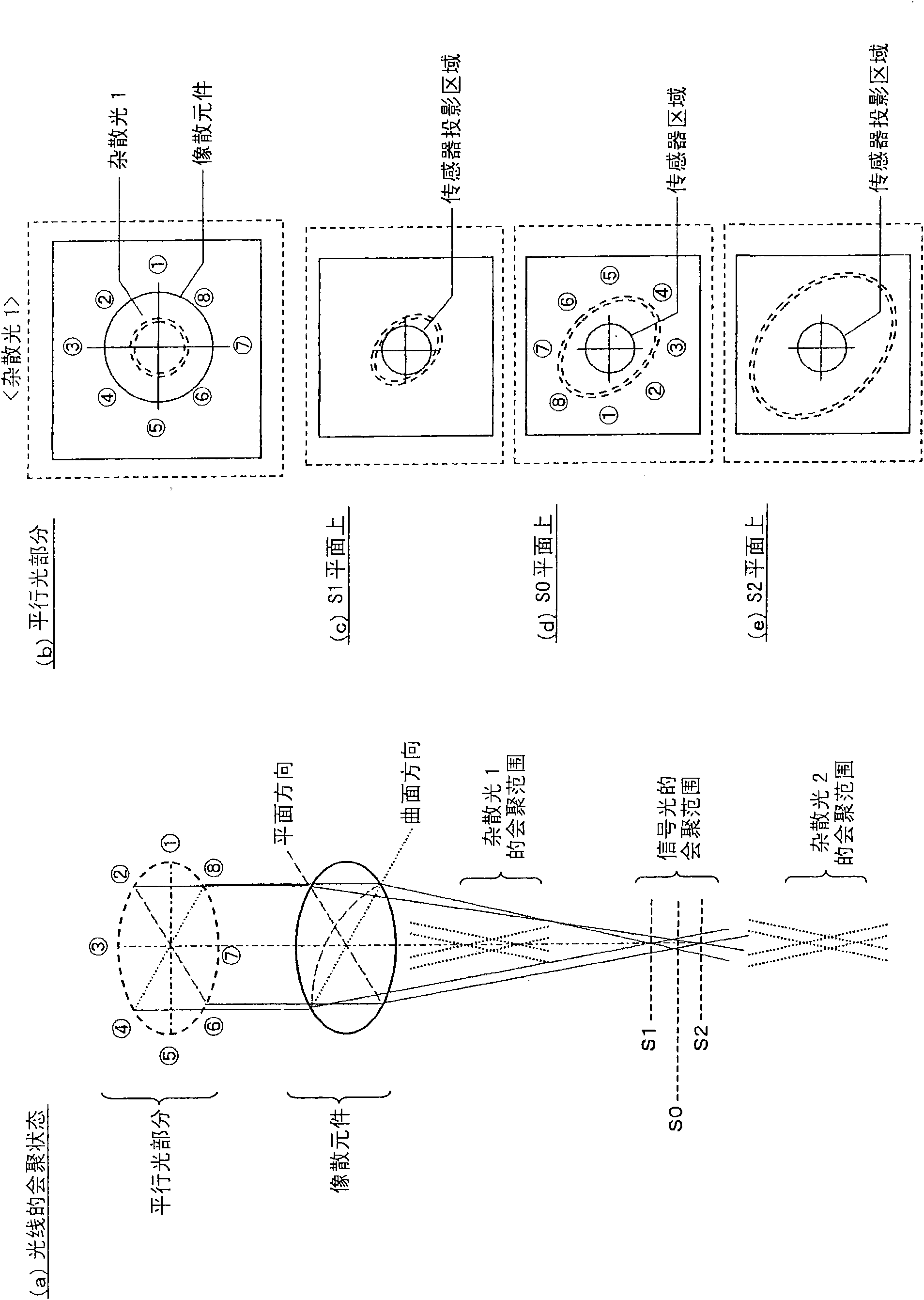

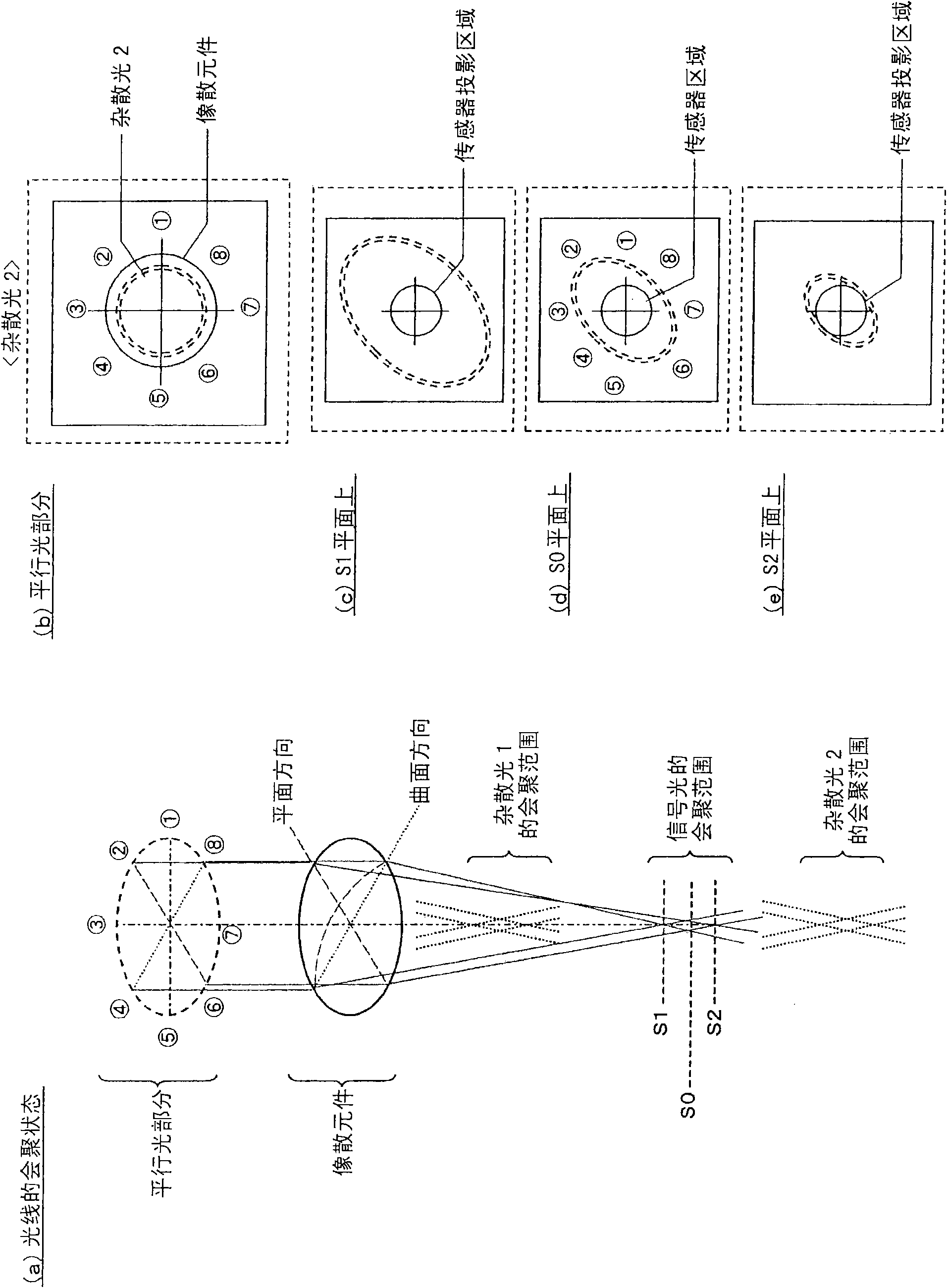

[0058] First, refer to Figure 1 to Figure 10 , to describe the technical principle applied in this embodiment.

[0059] figure 1 (a) is a diagram showing a converging state of signal light and stray light when laser light (signal light) reflected from a target recording layer enters an astigmatic element such as an anamorphic lens in a parallel light state. Among them, viewed from the side of the laser incident surface, "stray light 1" is the laser light reflected by the recording layer that is one layer deeper than the target recording layer, and "stray light 2" is the laser light that is on the outer layer than the target recording layer Laser light reflected by the recording layer. In addition, this figure shows the state when the signal light is focused on the target recording layer.

[0060] As shown in the figure, according to the action of the ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com