Manufacture method of semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as uneven filling of materials, achieve the effects of eliminating interlayer dielectric layer gap filling, expanding opening size, and easy deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution, and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

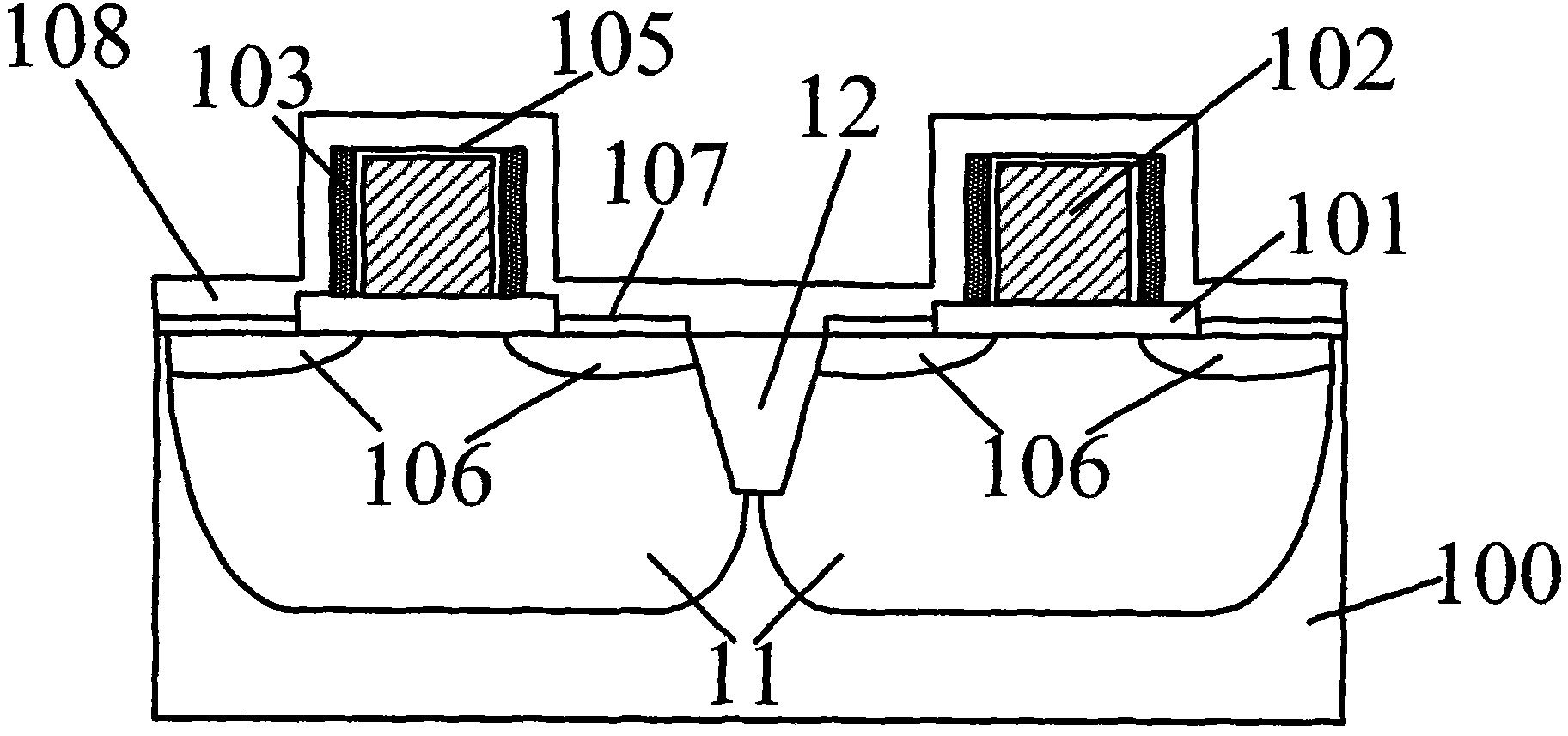

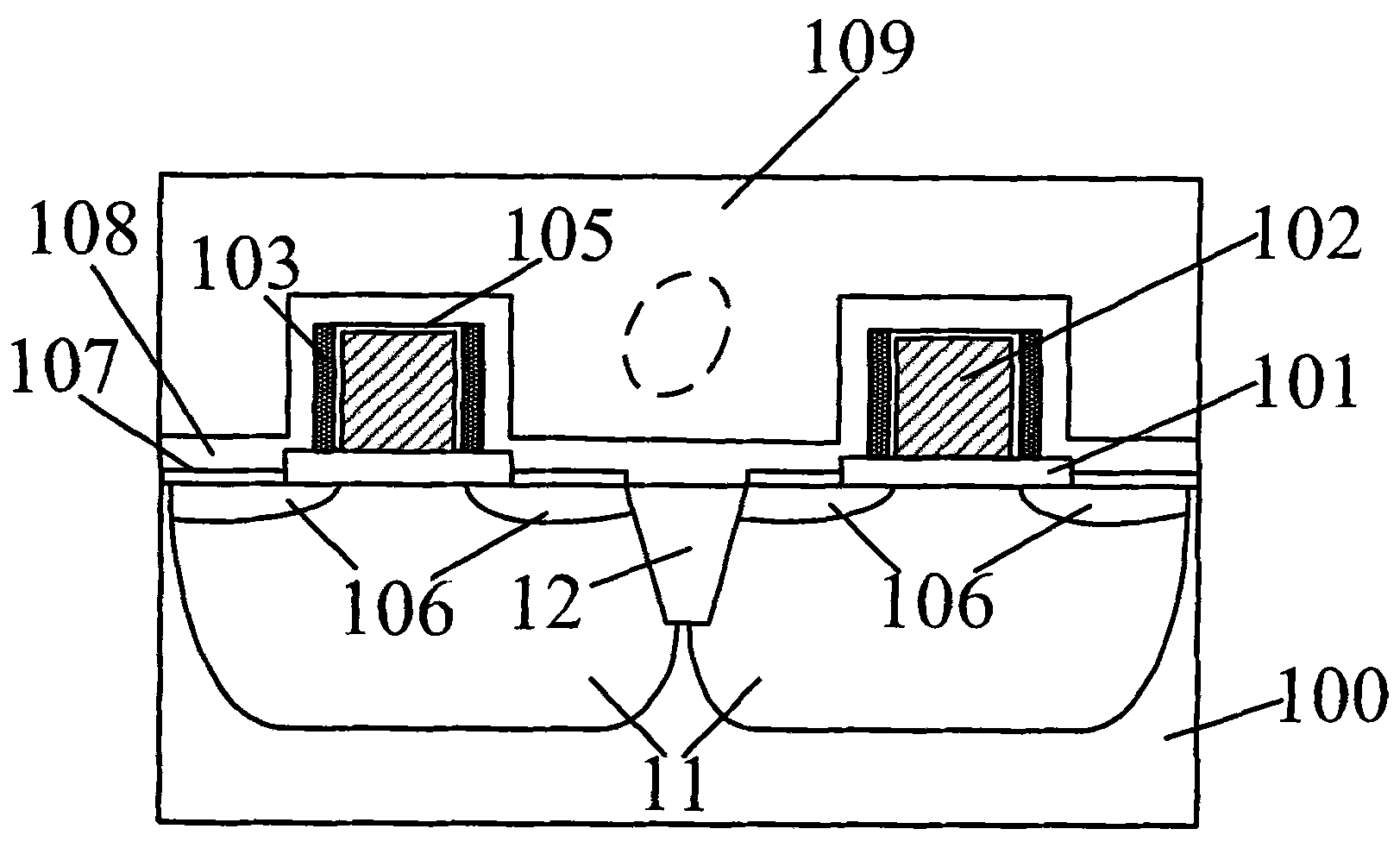

[0031] In the present invention, after etching back the nitride, the shape of the first sidewall layer is corrected so that the first sidewall layer has a tapered pointed shape. When the ILD material is deposited between the gate and the gate, the relative expansion The size of the opening between the gate and the gate is reduced, making it easier for the ILD material to be deposited in the area between the gate and the gate, thereby effectively eliminating the problem of interlayer dielectric layer gap fill (ILD gap fill).

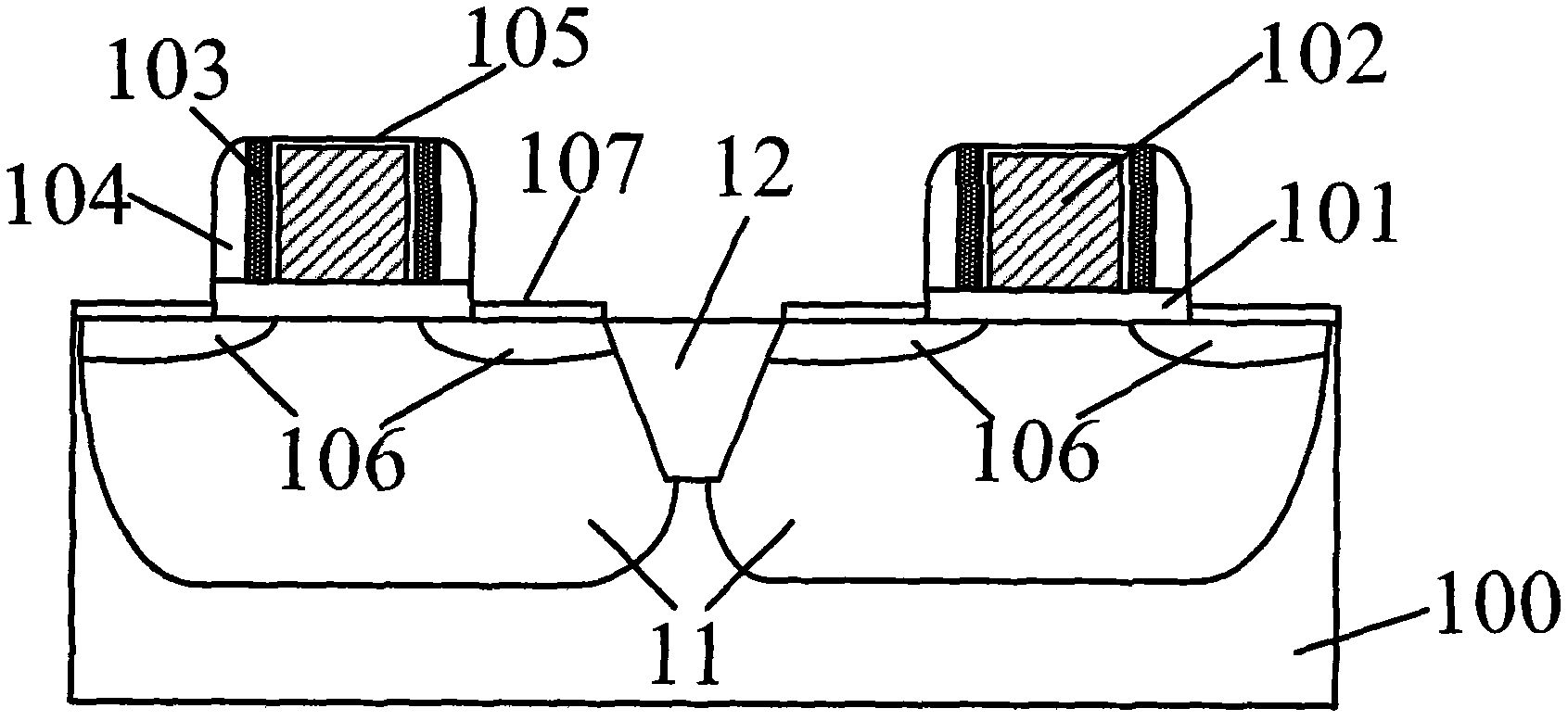

[0032] The present invention forms the fabrication method of the semiconductor device with ILD, below in conjunction with Figures 2a to 2c Describe in detail.

[0033] Such as Figure 2a As shown, a semiconductor substrate 100 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com