Method for manufacturing ceramic-base rigid circuit board

A manufacturing method and circuit board technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of difficulty in improving reliability, good thermal conductivity, poor thermal conductivity and heat dissipation, etc., and achieve high temperature resistance, high integration, and good thermal conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

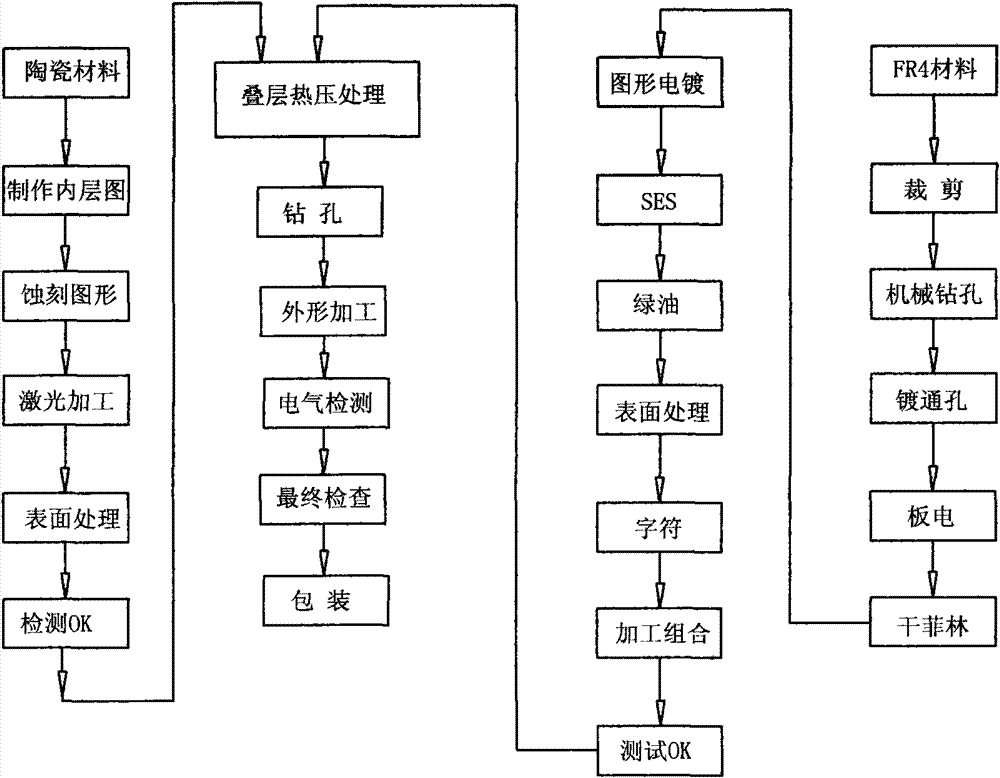

[0042] A method for manufacturing a ceramic-based rigid circuit board of the present invention comprises the following steps:

[0043] A. Making aluminum nitride ceramic circuit boards

[0044] a1. Make the inner layer graphics on the pretreated aluminum nitride ceramic copper clad laminate;

[0045] It mainly includes: incoming material inspection → degreasing → pickling → drying → film pressing → exposure → development → etching → film removal → drying and other processes;

[0046] The specific method is: clean the surface of the aluminum nitride ceramic copper clad substrate that has passed the inspection, use sodium persulfate to micro-etch the copper clad layer of the aluminum nitride ceramic copper clad substrate, and remove the oil and surface on the copper clad layer. Compared with the cleaning of the circuit board substrate by physical methods, it is more effective in preventing damage to the aluminum nitride ceramic copper-clad substrate, and the micro-etched alumin...

Embodiment 2

[0092] A method for manufacturing a ceramic-based rigid circuit board of the present invention comprises the following steps:

[0093] A. Making aluminum nitride ceramic circuit boards

[0094] a1. Make the inner layer graphics on the pretreated aluminum nitride ceramic copper clad laminate;

[0095] It mainly includes: incoming material inspection → degreasing → pickling → drying → film pressing → exposure → development → etching → film removal → drying and other processes;

[0096] The specific method is: clean the surface of the aluminum nitride ceramic copper clad substrate that has passed the inspection, use ammonium persulfate to micro-etch the copper clad layer of the aluminum nitride ceramic copper clad substrate, and remove the oil and surface on the copper clad layer. Compared with the cleaning of the circuit board substrate by physical methods, it is more effective in preventing damage to the aluminum nitride ceramic copper-clad substrate, and the micro-etched alum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com