Method for producing spherical stainless steel powder material by using high pressure water atomization method

A high-pressure water atomization, powder material technology, applied in the fields of precision casting, powder metallurgy and injection molding, can solve the problems of hindering sintering, high cost, irregular powder shape, etc., to achieve less pollution, low production cost, high sphericity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: 304 injection molding stainless steel powder production:

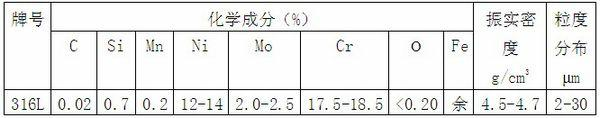

[0030] 1) Prepare the required stainless steel raw materials according to the content of each element in the stainless steel powder grade (Table 1);

[0031] 2) Add the above-mentioned stainless steel raw materials into the medium frequency induction heating furnace, and the superheat of the melt is 150°C;

[0032] 3) Pour the molten metal of the above stainless steel material into the crucible, and flow it down from the tundish 2, the flow rate of the molten metal is 40g / s;

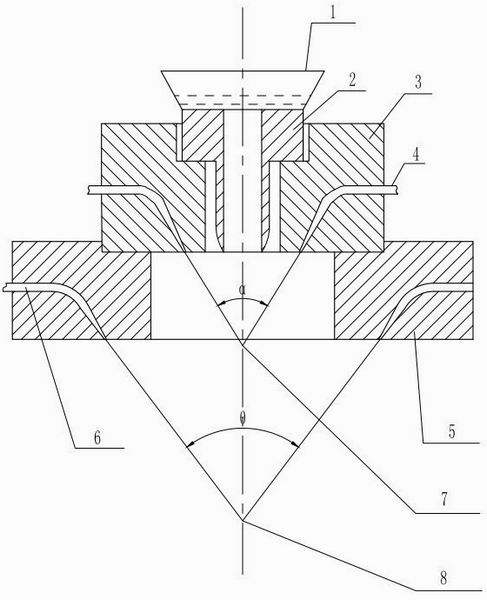

[0033] 4) Make high-pressure water spray from the nozzle of the atomizer with a water flow rate of 3.5 m 3 / min, the atomizer nozzle is a multi-focus jet double-layer annular nozzle, in which two main nozzles 4 and two sub-nozzles 6 are set, the spray angle α of the first focal point 7 is 17°, and the high-pressure water pressure is 50 Mpa, the spray angle θ of the second focal point 8 is 15°, and the high pressure water pr...

Embodiment 2

[0038] Example 2: Production of 316L injection molding stainless steel powder

[0039] 1) Prepare the required stainless steel raw materials according to the content of each element in the stainless steel powder grade (Table 1);

[0040] 2) Add the above-mentioned stainless steel raw materials into the medium frequency induction heating furnace, and the superheat of the melt is 180°C;

[0041] 3) Pour the molten metal of the above stainless steel material into the crucible 1 so that it flows down from the tundish 2, and the flow rate of the molten metal is medium 45g / s;

[0042] 4) Make high-pressure water spray out from the nozzle of the atomizer, and the water flow rate is 6m 3 / min, the atomizer nozzle is a double-layer annular nozzle with multi-focus jet, and two main nozzles 4 and two sub-nozzles 6 are set. The injection angle θ of the two focal points 8 is 16°, and the high pressure water pressure is 45Mpa.

[0043] The sphericity of the produced powder is 92%, and th...

Embodiment 3

[0046] Example 3: Production of 316L injection molding stainless steel powder

[0047] 1) Prepare the required stainless steel raw materials according to the content of each element in the stainless steel powder grade (Table 2);

[0048] 2) Add the above-mentioned stainless steel raw materials into the medium-frequency induction heating furnace, and the superheat of the melt is 200°C;

[0049] 3) Pour the molten metal of the above stainless steel material into the crucible 1, and then flow it down from the tundish 2, the flow rate of the molten metal is 38g / s;

[0050] 4) The high-pressure water is sprayed from the nozzle of the atomizer. The nozzle of the atomizer is a double-layer annular nozzle with multi-focus jet, and four main nozzles 4 and four auxiliary nozzles 6 are set. The spray angle of the first focal point 7 is α 18°, high pressure water pressure 70Mpa, second focus 8 jet angle θ is 16°, high pressure water pressure 60Mpa, water flow 5m 3 / min.

[0051] The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com