Meat processing waste water treatment process

A technology for meat processing and wastewater treatment, which is applied in animal processing wastewater treatment, biological water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problems of turbid water quality, perishable odor, and formation of scum, etc., to achieve Stable operation, convenient management and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

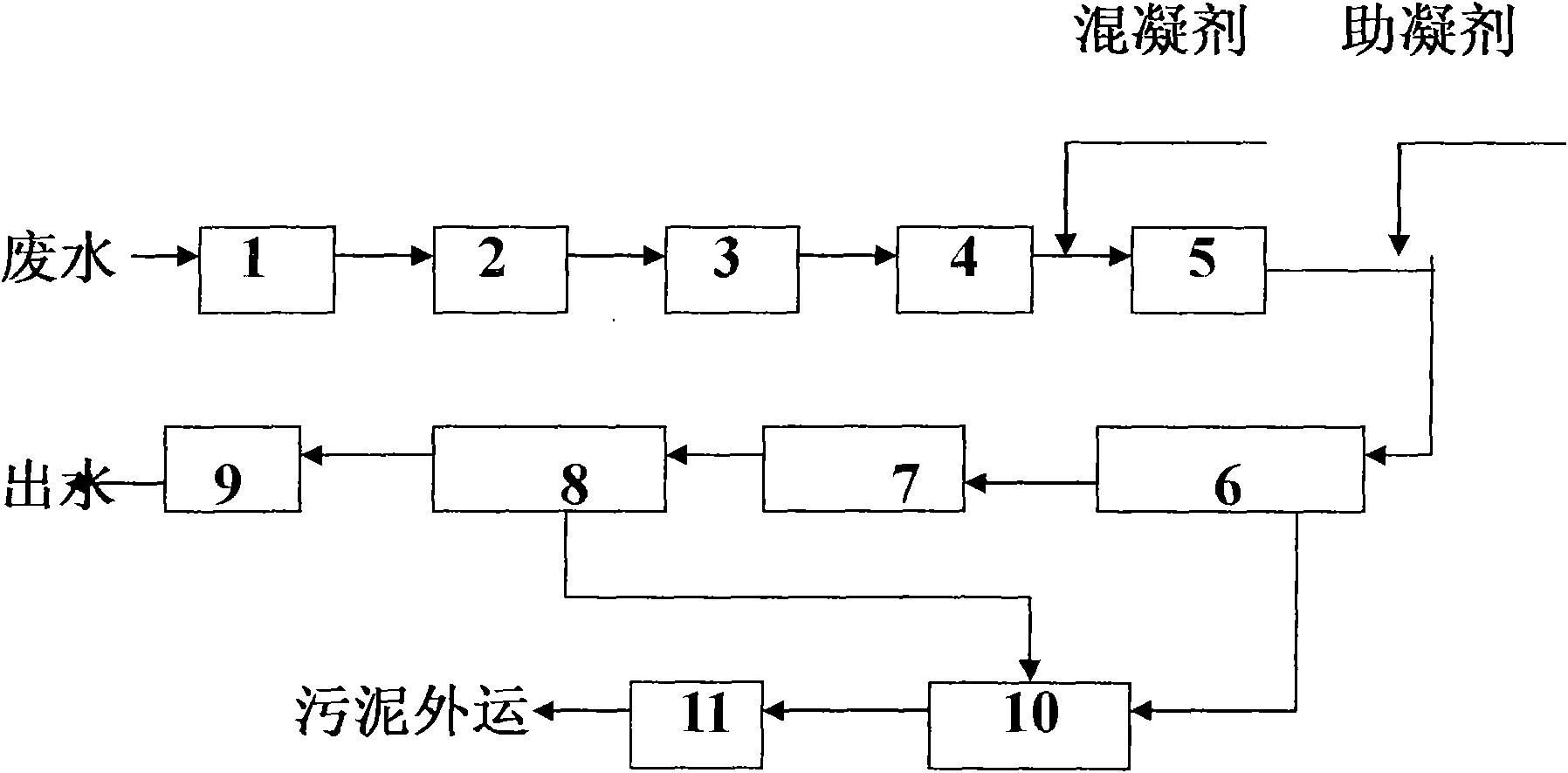

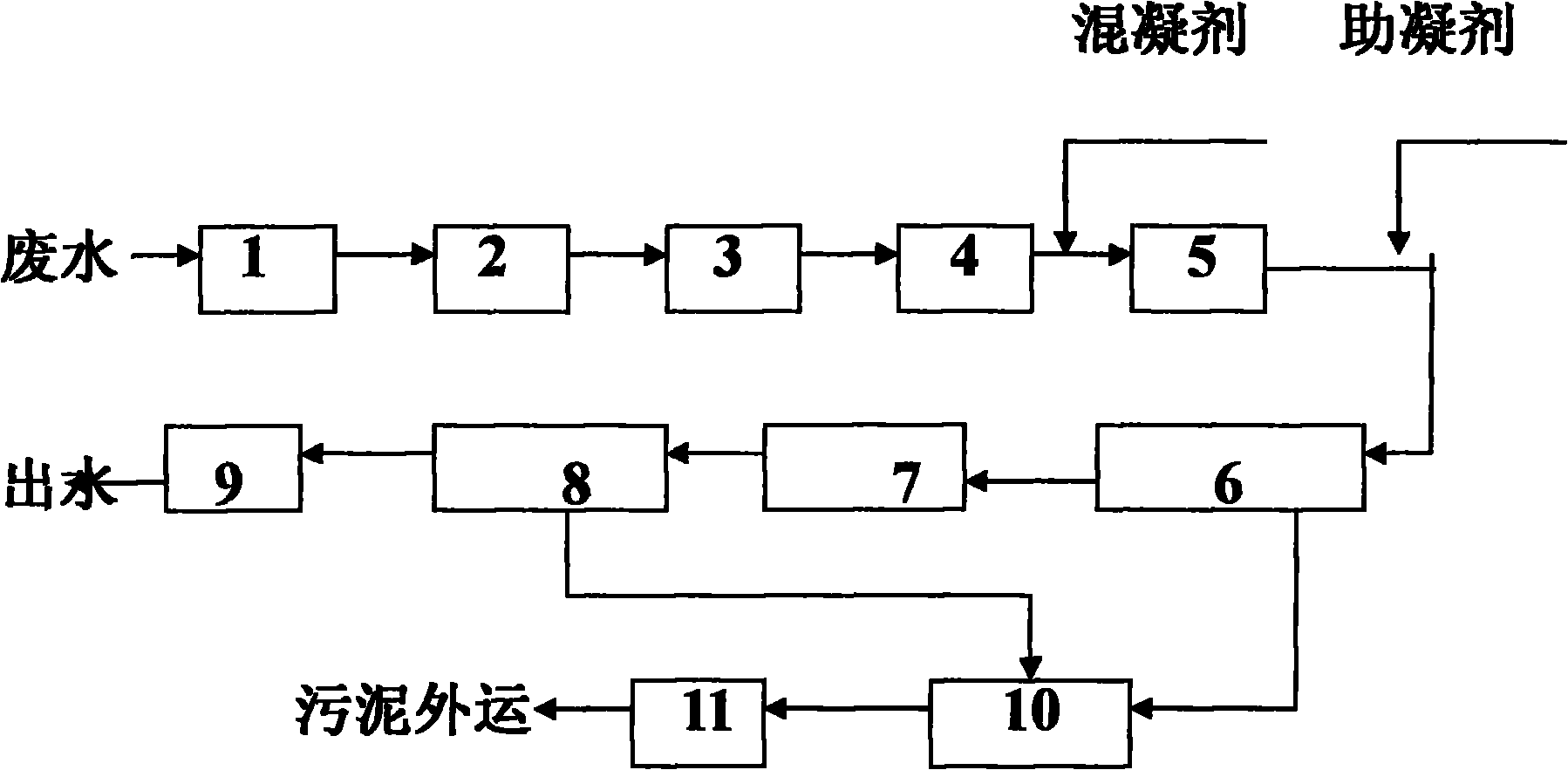

[0011] After the wastewater is desanded in the grit chamber and the water quality is adjusted in the regulating tank, it is upgraded to the high-efficiency CAF vortex air flotation system. The CAF vortex air flotation system removes most of the SS and COD in the wastewater, and then enters the contact oxidation tank for aerobic oxidation. biological treatment.

[0012] Major equipment:

[0013] 1. Grille

[0014] The waste water passes through the grid to remove part of the hair and suspended solids.

[0015] 2. Grit chamber

[0016] The advection type grit chamber is adopted, and the dust in the pond is regularly discharged through the sand discharge pipe at the bottom and enters the sand drying pond.

[0017] 3. Regulating pool

[0018] The water quality and quantity of meat processing wastewater fluctuate from time to time, and the regulating tank is used to adjust the water quantity.

[0019] 4. Lift the pump room

[0020] Two submersible sewage pumps are installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com